Concept

The decision to adhere to a restrictive standard is an act of strategic architecture. It represents a calculated choice to operate within a more demanding set of constraints than the market requires. This action redefines the very foundation of a business’s operational system, shifting its internal calculus from mere compliance to the pursuit of systemic excellence. Viewing standards through this lens reveals their true function ▴ they are powerful forcing mechanisms.

A restrictive standard compels an organization to achieve a higher state of efficiency, quality, or responsibility. It is a catalyst for introspection and innovation, demanding that a firm scrutinize its processes, eliminate latent inefficiencies, and develop superior operational capabilities. The competitive advantage, therefore, does not arise from the certificate on the wall. It is forged in the crucible of the changes required to earn it.

This process of transformation is a direct reflection of the principles articulated in the Porter Hypothesis. The hypothesis posits that stringent, well-designed regulations or standards can trigger innovations that offset the costs of compliance. By imposing limitations, a restrictive standard forces a company to solve problems its competitors are not even considering. This could manifest as the discovery of cleaner production technologies, the development of more efficient resource management protocols, or the creation of more resilient data security architectures.

The innovation effect makes production processes and products more efficient, and the resulting cost savings can be sufficient to overcompensate for the initial investment in compliance. A company that successfully navigates this path gains a first-mover advantage, leveraging its new capabilities, patents, and operational learning to establish a dominant competitive position long before regulations become mandatory or competitors recognize the strategic value of such high standards.

Adopting a restrictive standard is a deliberate act of system re-engineering designed to produce superior operational outcomes.

The advantage materializes across multiple dimensions of the business system. Operationally, the discipline required to meet a high standard streamlines workflows, reduces waste, and minimizes errors. This leads to lower production costs, improved product quality, and greater predictability in output. Strategically, it serves as a powerful signaling mechanism.

Certification to a restrictive standard communicates a commitment to quality, safety, or ethical conduct that builds profound trust with customers, partners, and investors. In an increasingly transparent and risk-averse market, such trust is a primary driver of brand loyalty and valuation. It can unlock access to premium markets, attract top-tier talent, and reduce the cost of capital by assuring stakeholders of minimized legal, reputational, and operational risks.

Ultimately, adhering to the most restrictive standard is an offensive strategy disguised as a defensive measure. It is a method for building a more robust, efficient, and resilient organization from the inside out. The standard itself is simply the blueprint; the competitive advantage is the superior operational structure that is built by following it.

This structure is difficult for competitors to replicate because it is embedded in the company’s culture, processes, and technological infrastructure. While others focus on meeting the minimum acceptable threshold, the standard-bearer is already operating at a higher level of performance, continuously refining the very systems that will define the next generation of competition.

Strategy

The strategic integration of restrictive standards into a business’s core operating model is what separates market leaders from mere participants. It is the deliberate process of transforming a compliance requirement into a value-generation engine. This requires moving beyond a reactive, checklist-based mentality to a proactive, architectural approach where standards are selected and implemented to amplify the company’s unique competitive positioning.

The success of this endeavor hinges on the precise alignment between the chosen standard and the firm’s overarching strategic objectives. A standard is not a one-size-fits-all solution; it is a specialized tool that must be wielded with purpose.

Frameworks for Strategic Implementation

A business can pursue several distinct strategic trajectories when leveraging restrictive standards. The choice of framework depends on the company’s market position, its core competencies, and its long-term vision. Each framework utilizes the standard as a lever to achieve a different kind of competitive advantage.

Operational Excellence through Systematization

This framework is centered on using standards like ISO 9001 to achieve profound internal efficiencies. The primary goal is to optimize processes, reduce waste, and enhance productivity, thereby lowering the cost base and improving margins. The standard acts as a catalyst for rigorous process mapping, documentation, and continuous improvement. By formalizing workflows and establishing clear metrics for performance, the organization eliminates ambiguity and reduces the potential for costly errors.

This systematization leads to more predictable outcomes, shorter lead times, and improved resource utilization. The competitive advantage is rooted in cost leadership, derived from a superiorly designed and managed operational system.

Differentiation through Trust and Reputation

In this framework, standards are employed as a means of building intangible brand equity. Adherence to stringent environmental standards (like ISO 14001), data security protocols (like SOC 2 or a proprietary, stricter framework), or ethical sourcing certifications signals a commitment to values that resonate with specific customer segments. This strategy is particularly effective in markets where customers are highly discerning and make purchasing decisions based on trust, safety, and corporate responsibility.

The standard becomes a verifiable proxy for quality and integrity, allowing the company to command premium prices, foster deep customer loyalty, and insulate itself from the reputational damage that can plague less disciplined competitors. The competitive advantage is differentiation, built on a foundation of demonstrable trustworthiness.

Innovation Leadership via First Mover Advantage

This framework embodies the core of the Porter Hypothesis. It involves proactively adopting or even helping to define emerging, highly restrictive standards before they become mainstream or mandated by regulation. By doing so, a company forces itself to innovate. It must develop new technologies, processes, and expertise to meet the demanding requirements of the new standard.

This journey of discovery often leads to valuable intellectual property, unique operational capabilities, and a deep understanding of future market dynamics. When the rest of the market is forced to adapt to the new standard, the first mover is already years ahead on the learning curve, holding key patents and enjoying a reputation as an industry pioneer. The competitive advantage is one of innovation leadership, secured by mastering the future before it arrives.

How Does Strategic Selection Amplify the Advantage?

The process of selecting which standard to pursue is a critical strategic decision. A poorly chosen standard can become a costly distraction, while a well-chosen one acts as a powerful accelerant. The selection process must be a deliberate exercise in strategic foresight, involving a deep analysis of market trends, customer values, and the company’s own internal capabilities.

- Strategic Goal Alignment ▴ The first step is to clearly articulate the primary strategic objective. Is the goal to become the lowest-cost producer, the most trusted brand, or the most innovative player in the industry? The answer to this question will narrow the field of potential standards to those that directly support the chosen path.

- Market And Stakeholder Analysis ▴ The organization must identify the standards that hold the most currency with its key stakeholders. This includes customers, investors, regulators, and employees. For a B2B technology firm, SOC 2 certification might be non-negotiable for winning enterprise clients. For a consumer goods company, a verifiable sustainability standard could be the key to unlocking a new demographic of environmentally conscious buyers.

- Capability And Gap Assessment ▴ A realistic assessment of the organization’s current capabilities is essential. The implementation of a restrictive standard requires significant resources, expertise, and commitment. A gap analysis will reveal the distance between the company’s current state and the requirements of the standard, allowing for a clear-eyed evaluation of the required investment in time, capital, and personnel.

- Future-Proofing And Regulatory Foresight ▴ The most strategic choices often anticipate future trends. By analyzing the direction of regulatory policy and societal expectations, a company can select a standard that not only provides an immediate advantage but also positions it favorably for the future. Adopting a strict data privacy standard today could provide a significant edge when inevitable data protection regulations are enacted tomorrow.

A standard’s value is not intrinsic; it is unlocked through its alignment with a coherent and well-executed business strategy.

The following table provides a comparative analysis of these strategic frameworks, illustrating how the same concept ▴ adhering to a restrictive standard ▴ can be deployed to achieve divergent business outcomes.

| Strategic Framework | Primary Objective | Exemplar Standard | Core Mechanism | Primary Locus of Advantage | Key Performance Indicators |

|---|---|---|---|---|---|

| Operational Excellence | Cost Leadership | ISO 9001 (Quality Management) | Process optimization, waste reduction, error minimization. | Internal Operations | Cost of Goods Sold (COGS), Overall Equipment Effectiveness (OEE), Defect Rate. |

| Differentiation Through Trust | Brand Equity & Premium Pricing | ISO 14001 (Environmental), SOC 2 (Security) | Signaling commitment to non-functional values (safety, ethics). | Market Perception | Customer Retention Rate, Net Promoter Score (NPS), Brand Trust Index. |

| Innovation Leadership | First-Mover Advantage | Early adoption of new environmental or tech standards | Forced innovation, IP generation, learning curve effects. | Technological Capability | Number of Patents Filed, R&D as % of Revenue, Time to Market for New Products. |

Ultimately, the strategic application of restrictive standards is about building a business that is fundamentally more robust. It is a commitment to constructing a system that is not only compliant with the rules of today but is also engineered to win the competition of tomorrow. The advantage it creates is durable because it is systemic, woven into the very fabric of how the organization operates, innovates, and interacts with the world.

Execution

The translation of a strategic decision to adopt a restrictive standard into a tangible competitive advantage occurs at the level of execution. This is where abstract goals are converted into concrete operational protocols, system architectures, and performance metrics. A flawless execution plan ensures that the standard is not merely adopted, but deeply integrated into the corporate DNA, creating systemic capabilities that are difficult for competitors to replicate.

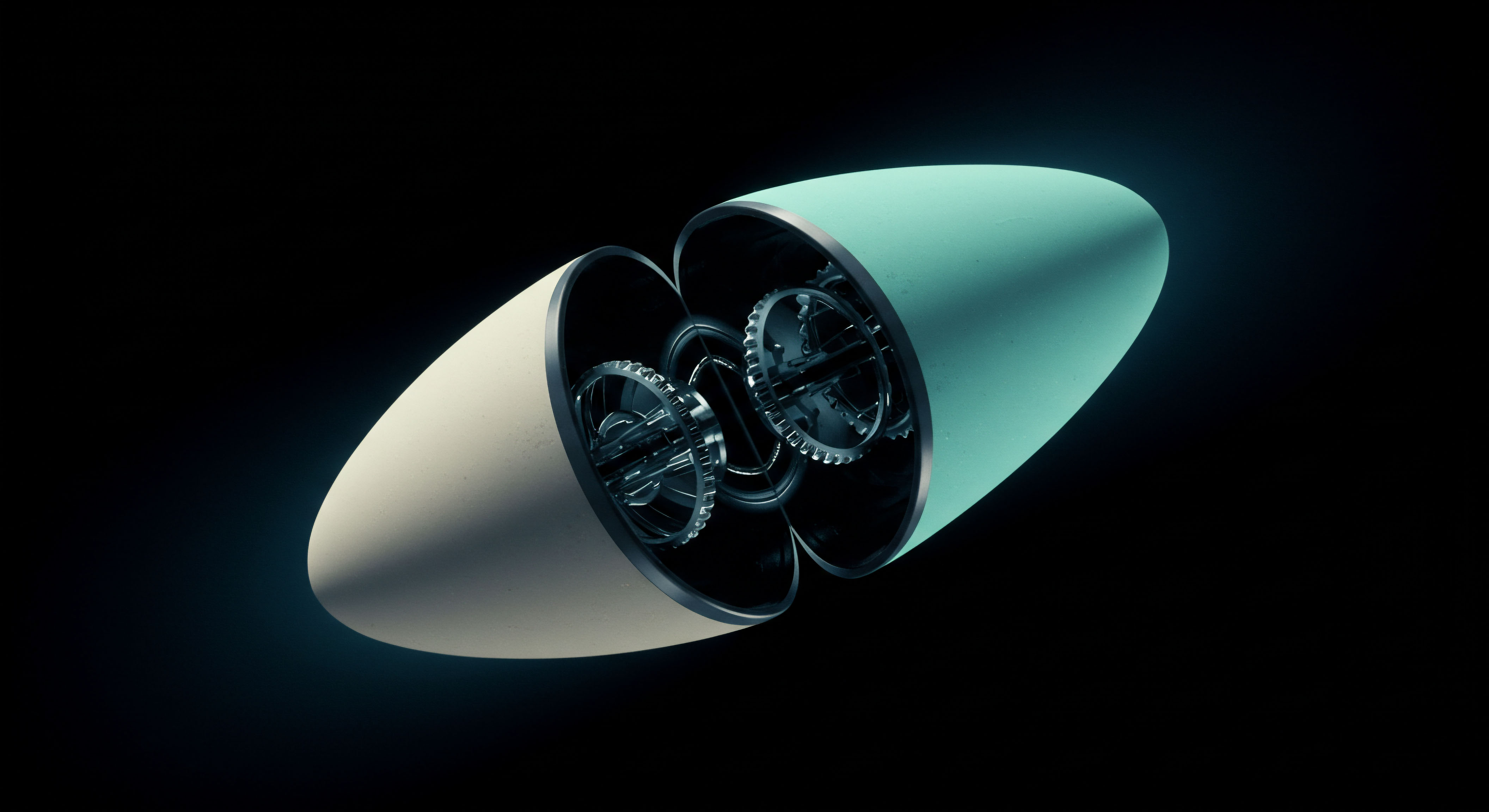

What follows is an in-depth examination of the execution process, using a hypothetical scenario of a mid-sized aerospace components manufacturer, “AeroForge Inc. ” that decides to proactively adopt “AS9100-Plus,” a fictional, highly restrictive standard that combines the rigorous quality requirements of AS9100 with cutting-edge environmental sustainability and supply chain traceability mandates.

The Operational Playbook for AS9100 plus Implementation

The execution for AeroForge is structured as a multi-phase project, managed with the same rigor as a critical product launch. Each phase has defined objectives, deliverables, and cross-functional teams responsible for its success.

Phase 1 Discovery and Systemic Gap Analysis

The initial phase is dedicated to understanding the full scope of the challenge. AeroForge cannot build a new system without first having a precise blueprint of its existing one.

- Comprehensive Process Mapping ▴ A dedicated team of process engineers and quality assurance specialists meticulously documents every workflow, from raw material intake to final product inspection and shipping. This includes mapping not just the physical flow of materials but also the flow of information and data across different enterprise systems.

- Multi-Dimensional Gap Analysis ▴ The documented processes are then audited against every clause of the AS9100-Plus standard. This analysis is conducted across three key dimensions ▴ quality management systems (QMS), environmental impact (energy usage, waste streams, emissions), and supply chain traceability (provenance of materials, supplier compliance).

- Technology Stack Assessment ▴ The IT architecture team evaluates the current ERP, MES (Manufacturing Execution System), and PLM (Product Lifecycle Management) systems to determine their capacity to support the new data collection, analysis, and reporting requirements of the standard. The output is a detailed report identifying specific software limitations and integration challenges.

Phase 2 System Re-Engineering and Technological Integration

This phase involves actively redesigning the operational core of the business to meet the new standard.

- Process Redesign Workshops ▴ Cross-functional teams are assembled to re-imagine the workflows identified as non-compliant or inefficient during the gap analysis. The focus is on embedding quality, sustainability, and traceability checks directly into the production process, rather than treating them as after-the-fact inspections.

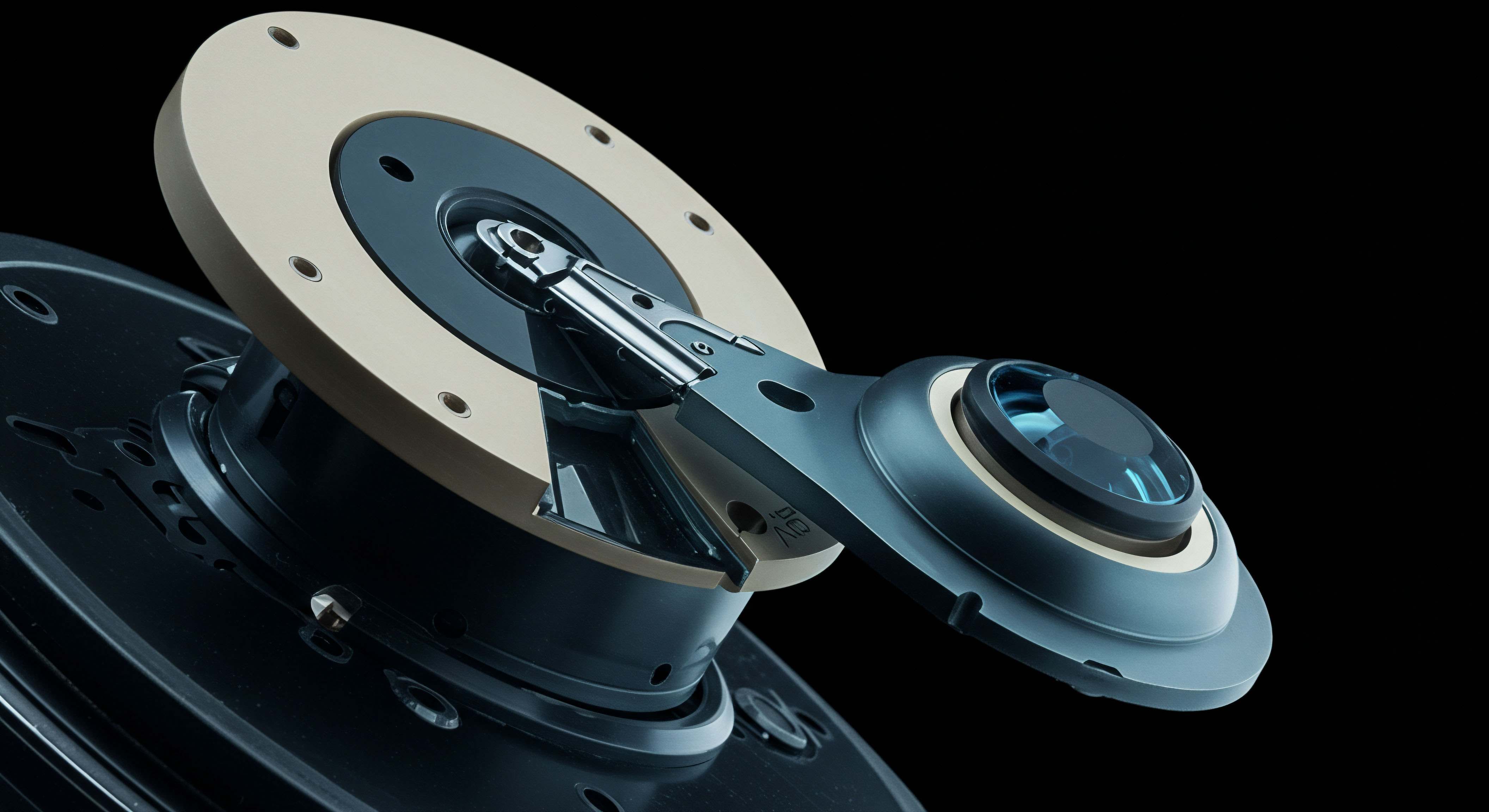

- Capital Investment And Upgrades ▴ Based on the technology assessment, AeroForge invests in new sensor technology for its CNC machines to monitor energy consumption in real-time. It also upgrades its MES to a version capable of creating a digital “birth certificate” for every component, tracking all materials, processes, and inspections from start to finish.

- ERP And MES Integration ▴ A major IT project is launched to create seamless data pipelines between the shop floor (MES) and the top floor (ERP). This ensures that sustainability metrics and traceability data are no longer siloed in operational systems but are integrated into the company’s core financial and planning software.

Phase 3 Supply Chain Fortification

AeroForge recognizes that its own compliance is contingent on the compliance of its suppliers. The AS9100-Plus standard requires traceability two tiers down the supply chain.

- Supplier Audit And Tiering ▴ All Tier-1 and critical Tier-2 suppliers are audited against the new standard’s requirements. They are then tiered into categories ▴ Fully Compliant, Compliance Roadmap Required, and High-Risk.

- Collaborative Compliance Programs ▴ For suppliers in the “Roadmap Required” category, AeroForge establishes joint task forces to help them upgrade their processes and systems. This collaborative approach strengthens relationships and builds a more resilient and capable supply network.

- Risk Mitigation And Diversification ▴ High-risk suppliers are phased out, and new, pre-vetted suppliers are brought on board. This process, while challenging, de-risks the supply chain from future disruptions related to quality or environmental non-compliance.

What Are the Quantifiable Returns on This Investment?

The decision to invest in such a demanding standard must be underpinned by a rigorous quantitative analysis. AeroForge’s leadership requires a clear model demonstrating that the benefits will eventually outweigh the substantial upfront and recurring costs. The following tables provide a simplified model of this analysis.

A well-executed standard implementation transforms operational costs into strategic investments with measurable returns.

Quantitative Modeling and Data Analysis

The financial viability of the AS9100-Plus project is continuously tracked using a detailed cost-benefit model. This model serves as a critical tool for project governance and for communicating the value of the initiative to the board and investors.

| Category | Item | Year 1 Cost ($) | Annual Recurring Cost ($) | Year 5 Projected Annual Benefit ($) | Notes |

|---|---|---|---|---|---|

| Investment Costs | Consulting & Gap Analysis | 250,000 | 0 | 0 | Upfront cost for external expertise. |

| Capital Equipment (Sensors, Filters) | 1,500,000 | 50,000 | 0 | New hardware for process monitoring and waste reduction. | |

| Software (MES/ERP Upgrade) | 750,000 | 150,000 | 0 | Licensing and maintenance for enhanced software. | |

| Training & Certification | 400,000 | 100,000 | 0 | Initial mass training and annual recertification fees. | |

| Operational Benefits | Energy Reduction | 0 | 0 | 350,000 | From real-time monitoring and process optimization. |

| Reduced Scrap/Rework Rate | 0 | 0 | 600,000 | Improved process control leads to fewer defects. | |

| Lower Insurance Premiums | 0 | 0 | 150,000 | Reduced risk profile acknowledged by insurers. | |

| Supply Chain Reliability Savings | 0 | 0 | 250,000 | Fewer disruptions and penalties from supplier issues. | |

| Strategic Benefits | Access to Premium Contracts | 0 | 0 | 1,200,000 | Winning contracts with clients mandating high standards. |

| Totals | 2,900,000 | 300,000 | 2,550,000 | Projected to reach positive ROI in Year 4. |

The second quantitative pillar of the execution plan is the rigorous measurement of the standard’s impact on the resilience and performance of the supply chain. A more compliant supply chain is a more predictable and higher-quality one.

| Metric | Supplier Tier | Pre-Standard Baseline | Post-Standard Target (Year 3) | Projected Improvement | Impact on AeroForge |

|---|---|---|---|---|---|

| On-Time Delivery Rate | Tier 1 | 92.5% | 99.0% | +6.5% | Reduced need for safety stock, improved production scheduling. |

| Tier 2 | 85.0% | 95.0% | +10.0% | Fewer downstream disruptions in Tier 1 production. | |

| Incoming Material Defect Rate | Tier 1 | 1,500 PPM | 200 PPM | -86.7% | Drastic reduction in rework and scrap costs. |

| Tier 2 | 4,000 PPM | 800 PPM | -80.0% | Improved quality of sub-components from Tier 1 suppliers. | |

| Compliance Documentation Accuracy | Tier 1 | 88.0% | 99.8% | +11.8% | Reduced administrative burden and audit risk. |

| Tier 2 | 70.0% | 98.0% | +28.0% | Full traceability and significantly lower risk of non-compliance. |

Predictive Scenario Analysis a Case Study in Execution

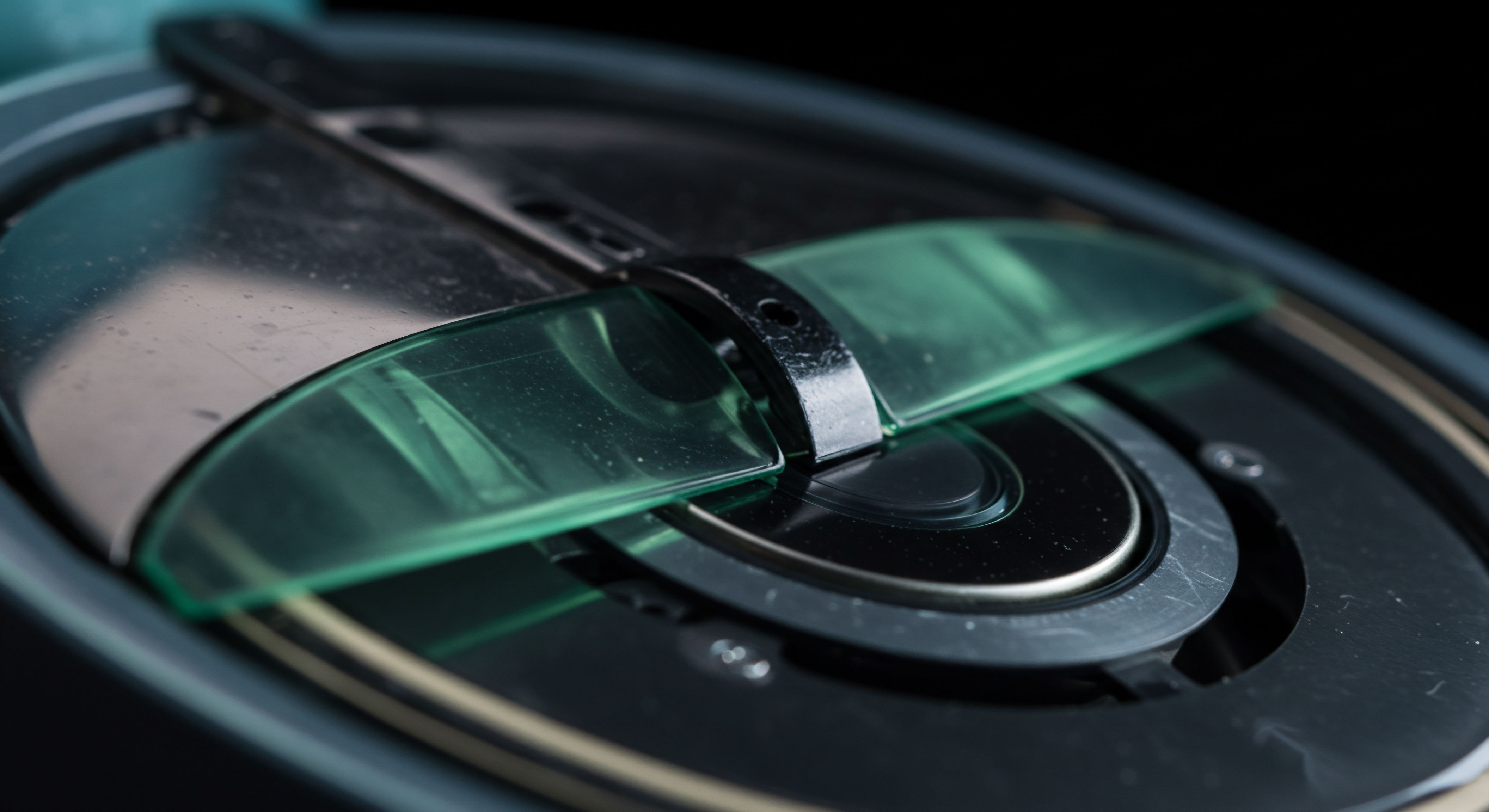

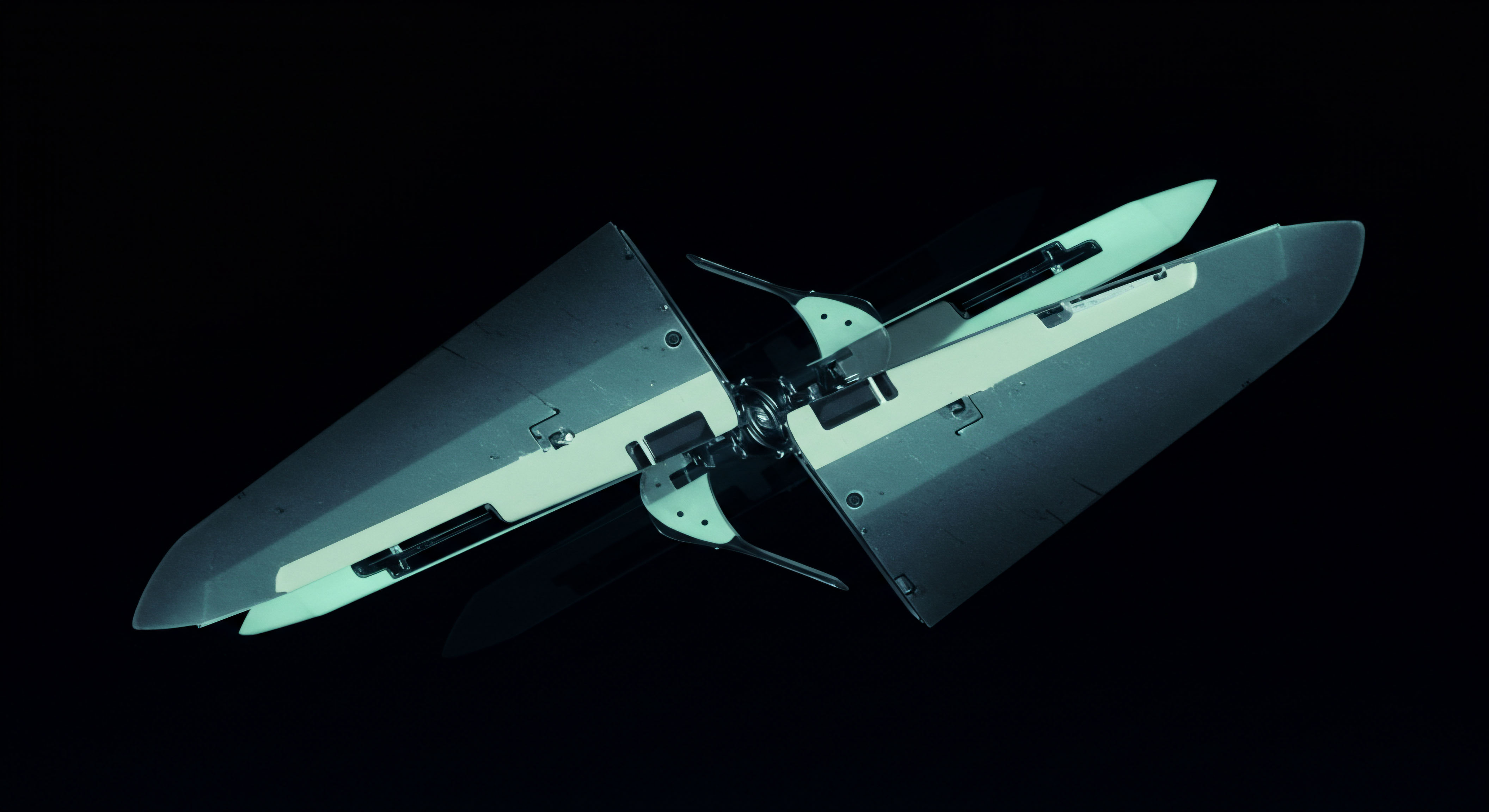

Two years after completing its AS9100-Plus certification, AeroForge bids on a major, multi-year contract to supply critical components for a new generation of electric vertical take-off and landing (eVTOL) aircraft. The client, a well-funded startup named “Urban Mobility Corp,” has built its entire brand on safety and sustainability. Their request for proposal (RFP) includes unusually strict requirements ▴ a maximum carbon footprint per component and full lifecycle traceability of all “exotic” materials. Most of AeroForge’s competitors, including a larger, lower-cost incumbent, are unable to meet these specific requirements.

Their existing systems cannot provide the granular data required. They can promise future compliance, but they cannot demonstrate current capability. AeroForge, in contrast, is able to respond to the RFP with a detailed data package generated directly from its integrated MES/ERP system. The package includes a full carbon accounting for the proposed components and a complete traceability report for every ounce of raw material, linked to its certified, AS9100-Plus compliant suppliers.

This demonstrable capability becomes the decisive factor. Urban Mobility’s procurement team sees that AeroForge has already built the systems and processes needed to guarantee the safety and sustainability they have promised to their own customers and investors. They award the contract to AeroForge, even though its bid is 5% higher than the incumbent’s. The contract’s value is more than triple the initial investment in the AS9100-Plus standard, vindicating the entire strategic initiative and establishing AeroForge as the leading supplier in the burgeoning eVTOL market. The competitive advantage was not won during the bidding process; it was secured two years earlier when the first process engineer began mapping the factory floor.

References

- Porter, Michael E. and Claas van der Linde. “Toward a New Conception of the Environment-Competitiveness Relationship.” Journal of Economic Perspectives, vol. 9, no. 4, 1995, pp. 97-118.

- Ambec, Stefan, et al. “The Porter Hypothesis at 20 ▴ Can Environmental Regulation Enhance Innovation and Competitiveness?” Review of Environmental Economics and Policy, vol. 7, no. 1, 2013, pp. 2-22.

- Tarí, Juan José, et al. “Benefits of the ISO 9001 and ISO 14001 standards ▴ A literature review.” Journal of Industrial Engineering and Management, vol. 5, no. 2, 2012, pp. 297-322.

- King, Andrew A. and Michael J. Lenox. “Does it Really Pay to Be Green? An Empirical Study of Firm Motivation for Proactive Environmental Management.” Journal of Industrial Ecology, vol. 5, no. 1, 2001, pp. 105-116.

- Johnstone, Nick, et al. “Environmental Policy Stringency and Foreign Direct Investment.” The B.E. Journal of Economic Analysis & Policy, vol. 10, no. 1, 2010.

- Wagner, Marcus. “The Role of Corporate Sustainability Performance for Economic Performance ▴ A Review of Astonishment.” Business Strategy and the Environment, vol. 24, no. 7, 2015, pp. 627-645.

- Heras-Saizarbitoria, Iñaki, and José F. Molina-Azorín. “ISO 9001 and ISO 14001 ▴ Towards a Research Agenda on Management System Standards.” International Journal of Management Reviews, vol. 14, no. 1, 2012, pp. 47-65.

- Albrecht, Johan. “Environmental Regulation, Comparative Advantage and the Porter Hypothesis.” Fondazione Eni Enrico Mattei, 1998.

Reflection

Designing the Resilient Firm

The journey through concept, strategy, and execution reveals a fundamental truth ▴ restrictive standards are architectural choices. The decision to adopt one is the decision to redesign the firm’s operating system from the ground up. The process forces a level of introspection that is rare in the day-to-day running of a business. It compels an organization to ask foundational questions about its purpose, its processes, and its position in the market.

What are the true drivers of value for our customers? Where are the hidden points of failure in our supply chain? How can we build a system that is not just profitable today, but resilient enough to thrive in the uncertain markets of tomorrow?

The knowledge gained from this process is a strategic asset in itself. It provides a map of the organization’s inner workings, revealing both its strengths and its vulnerabilities with unflinching clarity. This systemic self-awareness is the platform upon which true competitive advantage is built. It allows a leadership team to move beyond reactive problem-solving and begin proactively shaping their company’s destiny.

The standard ceases to be an external mandate and becomes an internal compass, guiding decisions on everything from capital allocation to talent development. Consider your own operational framework. Is it a product of deliberate design, or an accumulation of legacy processes? What forcing function could you introduce to catalyze its evolution toward a higher state of performance?

Glossary

Restrictive Standard

Competitive Advantage

Porter Hypothesis

First-Mover Advantage

Restrictive Standards

Iso 9001

Iso 14001

Gap Analysis