Concept

The operational cadence of a procurement department dictates the financial metabolism of the entire enterprise. Viewing this critical function as a series of disconnected tasks ▴ sourcing, ordering, paying ▴ creates a distorted picture, one that obscures profound inefficiencies. A more precise understanding frames procurement as a unified, data-centric operating system. Within this system, Key Performance Indicators (KPIs) are the primary data outputs, the continuous telemetry that signals the health and performance of the enterprise’s supply chain and fiscal discipline.

The automation of KPI tracking is therefore an architectural imperative. It represents the deliberate engineering of a system where performance data is generated, captured, and analyzed as an intrinsic property of the procurement process itself, a seamless flow of information that replaces the friction and latency of manual intervention.

This systemic view recasts the procurement professional from a process administrator into a systems analyst. Their primary function shifts from the manual compilation of reports to the strategic interpretation of real-time data streams. When technology is correctly applied, it does the work of data aggregation, freeing human capital to focus on exception handling, strategic sourcing, and supplier relationship management. The objective is to construct a procurement apparatus where every transaction, from requisition to final settlement, contributes to a live, multi-dimensional model of organizational spending and supplier performance.

This model becomes the foundation for predictive analytics and strategic decision-making, transforming a historically reactive cost center into a proactive value-generation engine. The core principle is that data has its highest value at the moment of its creation. Automated systems capture this value instantly, preventing the informational decay that plagues manual processes and enabling a level of operational agility previously unattainable.

Automating KPI tracking transforms procurement from a set of manual tasks into a cohesive, data-driven system that fuels strategic decisions.

The architecture of such a system is built upon the integration of disparate platforms ▴ Enterprise Resource Planning (ERP), procure-to-pay (P2P) suites, supplier management portals, and contract lifecycle management (CLM) tools. Through a carefully designed network of APIs and data warehouses, these once-siloed systems begin to function as a single, coherent entity. A purchase order created in a P2P system automatically updates inventory levels in the ERP. A supplier’s performance data, captured from delivery confirmations and quality inspections, dynamically adjusts their scorecard within a supplier relationship management (SRM) module.

This interconnectedness is the bedrock of automated KPI tracking. Metrics like ‘Procurement Cycle Time’ or ‘Spend Under Management’ are calculated automatically because the system captures the timestamps and data points at every stage of the process without human intervention. This systemic integrity ensures that the resulting KPIs are accurate, auditable, and available on demand, providing leadership with a trusted, real-time view of procurement operations.

Strategy

Developing a strategic framework for automating procurement KPIs requires a deliberate shift from a tool-centric mindset to a capability-centric one. The primary goal is the cultivation of specific operational capabilities ▴ real-time visibility, predictive cost modeling, systemic risk mitigation, and enhanced supplier collaboration. The technology is the enabler of these capabilities, the underlying infrastructure of a more intelligent procurement function. A successful strategy begins with a comprehensive mapping of the existing procurement value chain, identifying the points of highest friction, data loss, and manual effort.

This analysis provides the blueprint for a phased implementation, prioritizing automation where it can deliver the most significant impact on efficiency and strategic value. Organizations that achieve the highest returns on their technology investment approach automation as a continuous improvement cycle, beginning with foundational processes and progressively layering more sophisticated analytical and predictive capabilities.

The Phased Capability Rollout

A phased approach allows an organization to build momentum, demonstrate value, and manage the complexities of change without disrupting core operations. The strategy unfolds across distinct, sequential stages, each building upon the last to create a fully integrated and intelligent procurement ecosystem. This methodical progression ensures that both the technology and the organizational culture evolve in tandem.

- Foundational Data Integration ▴ The initial phase centers on creating a single source of truth for all procurement-related data. This involves integrating the core ERP system with procure-to-pay (P2P) platforms and contract management systems. The primary objective is to eliminate data silos and automate the flow of essential information, such as purchase orders, invoices, and supplier master data. Key KPIs automated at this stage include Spend Under Management and Purchase Order Accuracy.

- Process Automation and Control ▴ With a unified data foundation in place, the focus shifts to automating core transactional processes. This includes implementing automated three-way matching (purchase order, goods receipt, invoice), workflow-driven approvals, and electronic invoicing. This stage dramatically reduces manual processing times and error rates. KPIs such as Invoice Processing Cost and Procurement Cycle Time see significant improvement.

- Supplier Performance and Risk Management ▴ The third phase extends automation to the realm of supplier management. This involves deploying supplier portals for collaboration and implementing automated systems for tracking supplier performance against contractual obligations. Data on delivery times, quality acceptance rates, and compliance is captured systematically. This enables the automated calculation of Supplier Reliability and Quality Scorecard KPIs, providing an objective basis for supplier segmentation and development.

- Advanced Analytics and Strategic Sourcing ▴ The final phase leverages the accumulated data for strategic advantage. With a rich, clean dataset, the organization can deploy advanced analytics and AI-powered tools for spend analysis, cost modeling, and predictive risk identification. Strategic sourcing events are informed by deep insights into spending patterns and supplier performance, enabling procurement teams to negotiate from a position of informational strength.

Selecting the Appropriate Technological Framework

The choice of technology is a critical strategic decision that shapes the capabilities of the procurement function for years to come. The two dominant approaches are the integrated suite and the best-of-breed model. Each presents a different set of advantages and challenges, and the optimal choice depends on the organization’s existing technology landscape, internal capabilities, and long-term strategic goals.

An integrated suite offers a unified user experience and pre-built integrations, simplifying deployment. A best-of-breed approach provides deeper functionality in specific areas but requires a more significant investment in integration and data management.

The following table provides a comparative analysis of these two strategic technology frameworks, outlining their core attributes and implications for a procurement automation initiative.

| Attribute | Integrated Suite (e.g. SAP Ariba, Coupa) | Best-of-Breed (e.g. Zycus for Analytics, Ivalua for P2P) |

|---|---|---|

| Integration | Offers pre-built, seamless integration between modules (sourcing, contracting, P2P). Simplifies data flow and reduces initial implementation complexity. | Requires dedicated integration efforts, often using middleware or custom APIs, to connect specialized applications from different vendors. |

| Functionality | Provides broad functionality across the entire procurement lifecycle. May lack the deep, specialized features of a dedicated point solution. | Delivers deep, specialized functionality and innovation within a specific niche (e.g. advanced spend analytics, direct materials sourcing). |

| User Experience | A consistent user interface and experience across all modules, which can accelerate user adoption and reduce training requirements. | Variable user experiences across different applications, potentially requiring more extensive training and change management. |

| Vendor Management | Consolidates vendor relationship and support into a single point of contact, simplifying contract management and issue resolution. | Involves managing multiple vendor relationships, contracts, and support channels, which can increase administrative overhead. |

| Scalability & Flexibility | Scalability is managed by a single vendor. Can be less flexible in adapting to unique or highly specialized business processes. | Offers greater flexibility to select and replace individual components as business needs evolve or new technologies emerge. |

Execution

The execution of a procurement automation strategy is a complex systems engineering project. It demands a granular understanding of processes, data flows, and technological capabilities. Success hinges on a meticulously planned operational playbook that translates strategic objectives into concrete actions, technological configurations, and performance metrics.

This playbook serves as the definitive guide for the transformation, ensuring that all stakeholders, from IT to finance to procurement, are aligned on the objectives, methodologies, and expected outcomes. The core of this execution phase is the systematic instrumentation of the entire procure-to-pay lifecycle, ensuring every critical event is captured as a data point for real-time analysis and control.

The Operational Playbook for Implementation

This playbook outlines the critical steps for deploying an automated KPI tracking system within the procurement function. It is designed as a sequential, multi-stage process that ensures a robust and scalable implementation. This is where the theoretical gives way to the practical, where system configurations meet business process realities. There’s a certain intellectual friction here, a necessary grappling with the messy details of legacy systems and ingrained human behaviors.

It is within this friction that the true value of the system is forged. The process requires a relentless focus on data integrity, as the quality of the automated KPIs is a direct function of the quality of the underlying data.

- Step 1 ▴ KPI Definition and Baseline Measurement. Before any technology is implemented, the project team must finalize the specific KPIs that will be tracked. For each KPI, a precise definition, formula, and data source must be documented. Following this, a baseline measurement must be established using existing manual processes. This baseline is the critical benchmark against which the success of the automation project will be measured.

- Step 2 ▴ Process Mining and Optimization. Utilizing process mining software, the team analyzes the existing procurement workflows to identify bottlenecks, deviations, and inefficiencies. This data-driven analysis provides an objective map of how processes are actually executed, often revealing discrepancies with official documentation. The workflows are then redesigned and optimized for automation before being configured in the new system.

- Step 3 ▴ System Configuration and Integration. This is the primary technical phase. The chosen procurement platform (whether a suite or best-of-breed) is configured to match the optimized processes. This involves setting up approval workflows, configuring business rules for three-way matching, and defining user roles and permissions. Crucially, robust integrations are built to the ERP for financial data, the CLM for contract data, and any other relevant systems.

- Step 4 ▴ User Acceptance Testing (UAT) and Training. A cross-functional team of end-users conducts rigorous testing of the system using real-world scenarios. This UAT phase is designed to identify any gaps in configuration or usability before go-live. Concurrent to UAT, a comprehensive training program is rolled out to all users, focusing on the new workflows and the benefits of the automated system.

- Step 5 ▴ Go-Live and Hypercare. The system is launched, and a period of “hypercare” begins, typically lasting 2-4 weeks. During this time, the project team provides intensive support to end-users, quickly resolving any issues that arise. Automated KPI dashboards are closely monitored to ensure data is flowing correctly and metrics are being calculated as expected.

- Step 6 ▴ Continuous Improvement and Value Realization. Post-launch, the focus shifts to ongoing optimization. The procurement analytics team regularly reviews the KPI dashboards to identify trends and opportunities for further improvement. They work with category managers and sourcing specialists to use the insights from the system to drive strategic initiatives, such as supplier consolidation, contract renegotiation, and demand management.

Quantitative Modeling and Data Analysis

The heart of an automated procurement system is its ability to generate, process, and present data for quantitative analysis. The table below details a selection of core procurement KPIs, moving beyond simple definitions to specify the data sources, automation mechanisms, and strategic implications of each. This level of granularity is essential for building a system that delivers trusted, actionable intelligence. The entire structure is designed to convert raw transactional data into a clear view of operational performance.

A successful execution playbook translates strategic goals into tangible system configurations and precisely defined, automated performance metrics.

| Key Performance Indicator (KPI) | Formula / Definition | Primary Data Sources | Automation Mechanism | Strategic Implication |

|---|---|---|---|---|

| Procurement Cycle Time | Time from approved purchase requisition to confirmed goods receipt. | P2P System (Requisition Timestamp), ERP System (Goods Receipt Timestamp). | System automatically calculates the delta between the two timestamps for each completed order and aggregates the average. | Identifies bottlenecks in the sourcing and fulfillment process. Shorter cycle times improve operational agility and reduce lead time variability. |

| Spend Under Management (SUM) | (Total spend actively managed by procurement) / (Total addressable spend). | Spend Analytics Platform, ERP Vendor Payment Data. | The analytics platform categorizes all organizational spend and flags transactions associated with procurement-led contracts or sourcing events. | Measures the influence and control of the procurement function. Higher SUM correlates with greater cost savings and risk mitigation. |

| Invoice Processing Cost | (Total cost of AP department) / (Total number of invoices processed). | AP Automation System, ERP Financials. | The system tracks the number of invoices processed electronically versus manually, allowing for a weighted average cost calculation. | Directly measures the efficiency of the procure-to-pay process. Automation dramatically lowers this cost by reducing manual labor. |

| Supplier On-Time Delivery Rate | (Number of orders received on or before the requested date) / (Total number of orders). | ERP (Requested Delivery Date, Actual Receipt Date). | The system compares the requested delivery date on the PO with the actual goods receipt date in the ERP for every line item. | A critical measure of supplier reliability. Poor performance impacts production schedules and can lead to stockouts. |

| First-Pass Match Rate | (Number of invoices that match PO and goods receipt without manual intervention) / (Total number of invoices). | P2P or AP Automation System. | The system’s three-way matching engine automatically logs successful matches versus exceptions that require manual review. | Indicates the quality of purchasing data and supplier invoicing accuracy. A high rate signifies a highly efficient, touchless P2P process. |

| Procurement ROI | (Annual cost savings + Cost avoidance) / (Annual cost of procurement operations). | Spend Analytics, e-Sourcing Platform, ERP Financials. | The system tracks and aggregates savings documented in sourcing events and contract negotiations against the operational budget of the procurement department. | The ultimate measure of the procurement function’s value contribution to the enterprise. |

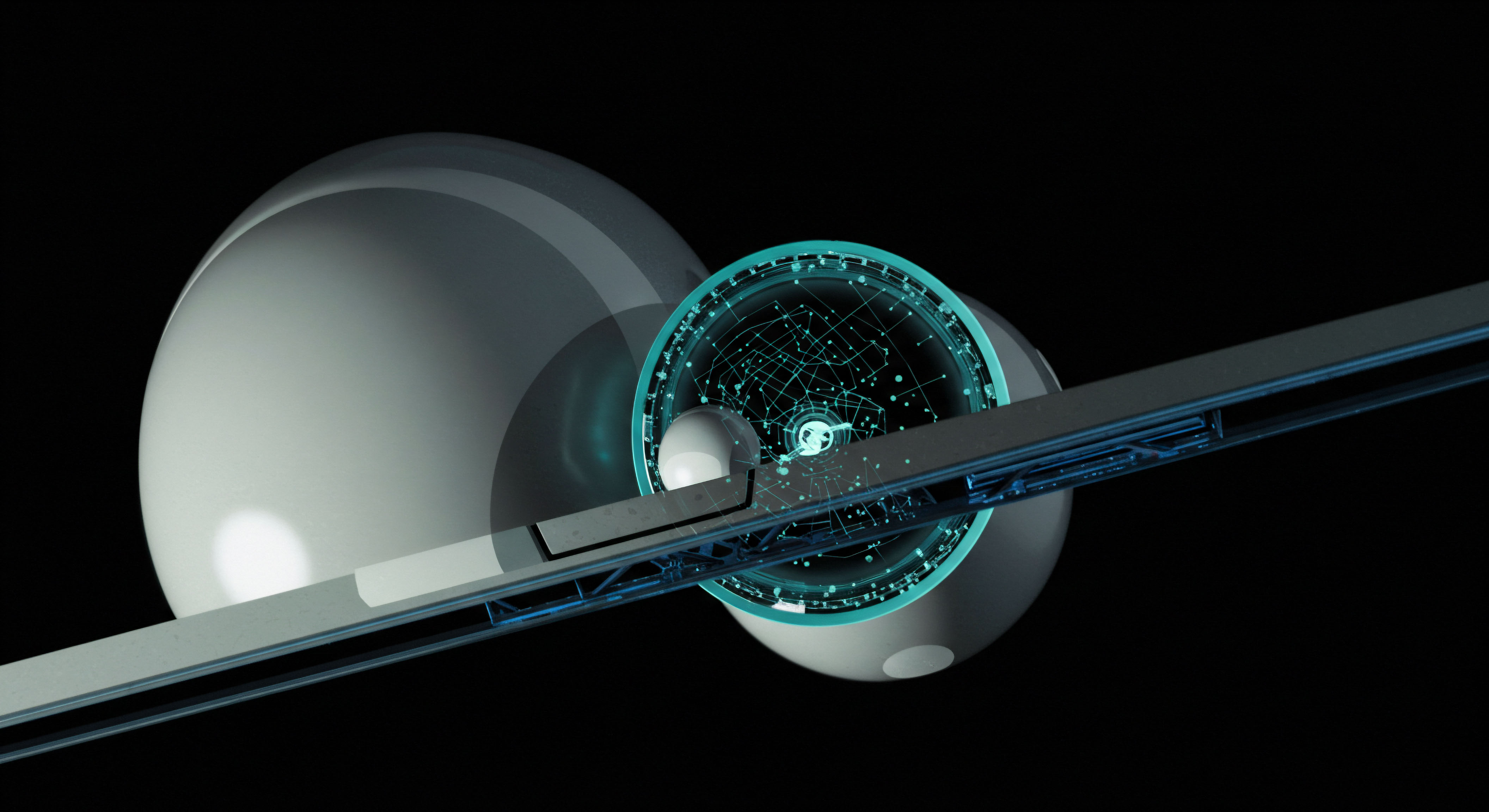

System Integration and Technological Architecture

The technological architecture for an automated procurement system is a federated model, with a central analytics and process management layer orchestrating data and workflows across several specialized systems. The design prioritizes seamless data flow and a unified user experience, abstracting the complexity of the underlying systems from the end-user. The diagram below illustrates a common architectural pattern.

The core components of this architecture are:

- Enterprise Resource Planning (ERP) System ▴ This is the system of record for financial data, vendor master files, and inventory. It is the ultimate destination for approved invoices and the source of payment information.

- Procure-to-Pay (P2P) Suite ▴ This is the primary transactional engine, managing the process from requisition through to invoice approval. It houses the workflows, the three-way matching engine, and the user interface for most procurement staff.

- Data Warehouse & Analytics Platform ▴ This is the intelligence layer. It extracts data from the ERP, P2P suite, and other sources via APIs. Within this platform, data is cleansed, transformed, and loaded into analytical models that power the KPI dashboards and spend analysis tools.

- Supplier Portal ▴ This web-based interface provides a secure channel for suppliers to receive purchase orders, submit invoices, and update their information. It is a critical component for improving supplier collaboration and data accuracy.

The integration between these systems is typically managed through a combination of pre-built connectors (common for major ERP and P2P platforms) and custom-developed APIs for more specialized applications. A robust integration strategy is the single most important technical factor in the success of the project. A failure here results in data silos, manual workarounds, and a complete loss of trust in the automated KPIs. It is the absolute foundation.

This requires a significant upfront investment in technical discovery and development, a fact that is often underestimated in initial project planning. The long-term stability and value of the entire system are dependent on the quality and resilience of these data pathways. Without them, the system is merely a collection of expensive, disconnected software licenses. With them, it becomes a true nervous system for the enterprise’s supply-side operations.

The architecture’s integrity depends entirely on the quality of its integrations; these data pathways are what elevate a collection of software into a cohesive intelligence system.

This entire structure is designed to create a virtuous cycle of data. Better processes in the P2P suite generate cleaner data. Cleaner data flows into the analytics platform, producing more accurate and insightful KPIs. These insights empower procurement professionals to make better strategic decisions, such as negotiating better contracts or rationalizing the supplier base.

These strategic actions are then executed back through the P2P suite, and the cycle begins again, with each iteration delivering incremental improvements in efficiency and cost savings. This is the engine of modern procurement.

References

- Batenburg, Ronald. “E-procurement adoption by European firms ▴ A quantitative analysis.” Journal of purchasing and supply management 13.3 (2007) ▴ 182-192.

- Flechsig, Christian, et al. “The Impact of Intelligent Process Automation on Purchasing and Supply Management ▴ Initial Insights from a Multiple Case Study.” Proceedings of the 28th European Conference on Information Systems (ECIS), 2020.

- Joshi, Rahul. E-supply Chain Collaboration and Logistics. Cengage Learning, 2009.

- Lyson, Kenneth, and Brian Farrington. Purchasing and supply chain management. Pearson Education, 2006.

- McKinsey & Company. “Strategic procurement ▴ The new catalyst for value creation.” McKinsey & Company Report, 2023.

- Nicoletti, Bernardo. Procurement 4.0 and the Fourth Industrial Revolution ▴ The Opportunities and Challenges of a Digital World. Springer Nature, 2020.

- Patrucco, Andrea S. Antonella Moretto, and Stefano Ronchi. “The impact of lean and agile procurement practices on supply chain performance.” International Journal of Production Economics 210 (2019) ▴ 147-161.

- Schoenherr, Tobias. “Procurement 4.0 ▴ The digital transformation of procurement.” Business Horizons 62.6 (2019) ▴ 739-750.

- Yuchtman, Ephraim, and Stanley E. Seashore. “A system resource approach to organizational effectiveness.” American sociological review (1967) ▴ 891-903.

- Zycus. “Procurement Efficiency Metrics & AI ▴ A Strategic Guide for 2025.” Zycus White Paper, 2024.

Reflection

From Measurement to Foresight

The assembly of an automated procurement system provides the organization with a new sensory apparatus, one capable of perceiving its own operational metabolism in real time. The initial value is found in the clarity of this new perception, the ability to measure and manage with a precision that was previously impossible. Yet, the ultimate potential of this system extends beyond mere measurement.

The rich, structured, and continuous flow of data it produces is the raw material for foresight. The historical record of cycle times, supplier performance, and price volatility becomes the training ground for predictive models.

The Emergence of a Predictive Capability

With sufficient historical data, the system can begin to anticipate future states. It can forecast commodity price fluctuations based on market indices and past purchasing behavior. It can predict which suppliers are at high risk of late delivery based on recent performance trends. It can model the budget impact of proposed sourcing decisions before they are made.

This predictive capability fundamentally changes the posture of the procurement function. It moves from reacting to events that have already occurred to proactively shaping future outcomes. The conversation shifts from “What was our spend last quarter?” to “What is our optimal spend profile for the next quarter, given our demand forecast and market risk assessment?” This evolution from rearview mirror reporting to forward-looking guidance is the final destination of the automation journey, representing the full realization of procurement as a strategic, data-driven entity.

Glossary

Kpi Tracking

Supplier Relationship Management

Supplier Performance

Procure-To-Pay

P2p

Procurement Cycle Time

Spend under Management

Procurement Function

Invoice Processing Cost

Three-Way Matching

Strategic Sourcing

Procurement Automation

Automated Procurement System

Automated Procurement