Concept

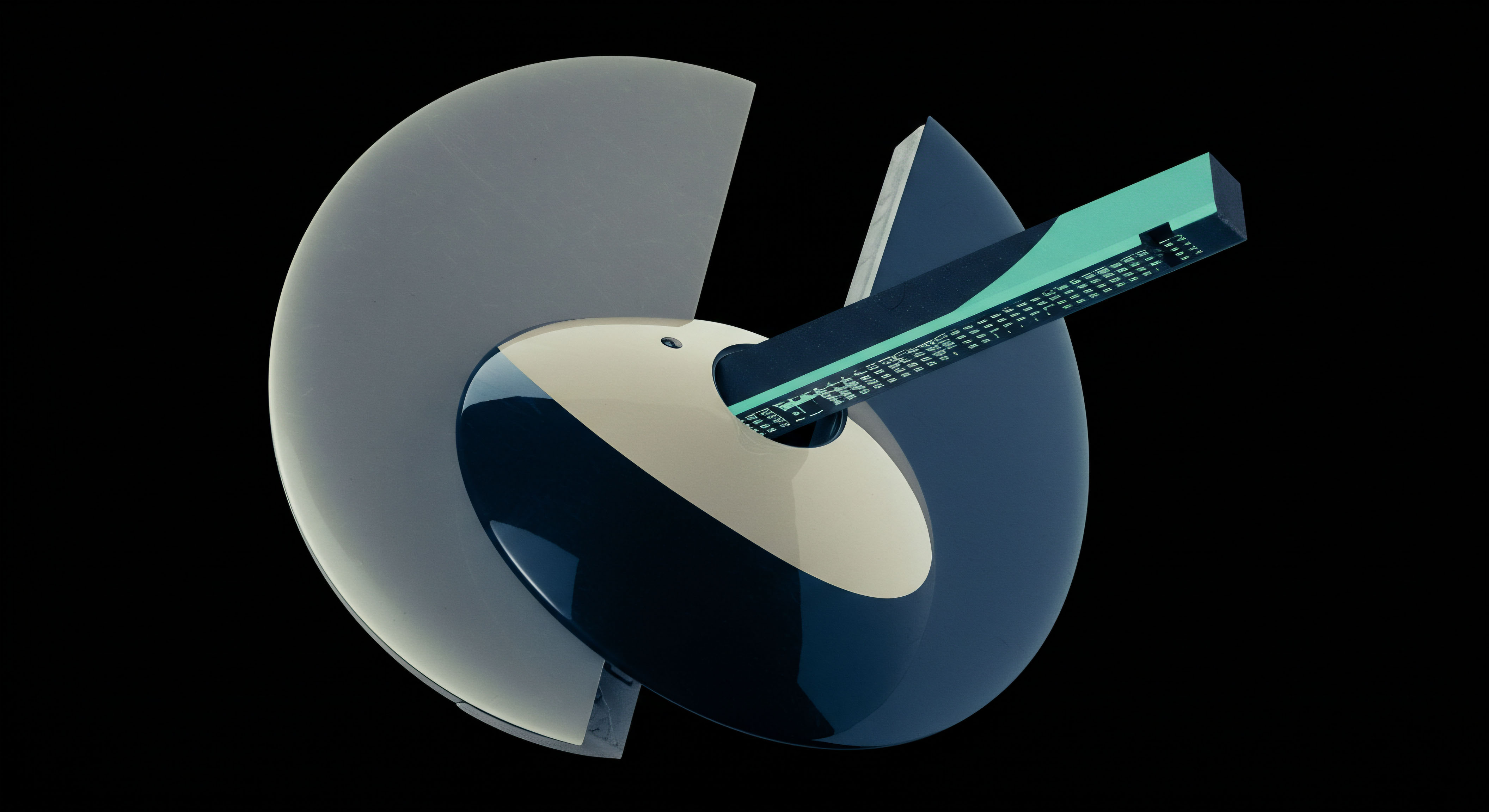

The decision to centralize Request for Proposal (RFP) communications fundamentally recalibrates the operational identity of a procurement team. This transformation moves the function from a series of disconnected, tactical purchasing actions into a cohesive, strategic intelligence hub. Centralization is an organizational design choice that consolidates the flow of all supplier-related inquiries, negotiations, and data through a single, authoritative channel.

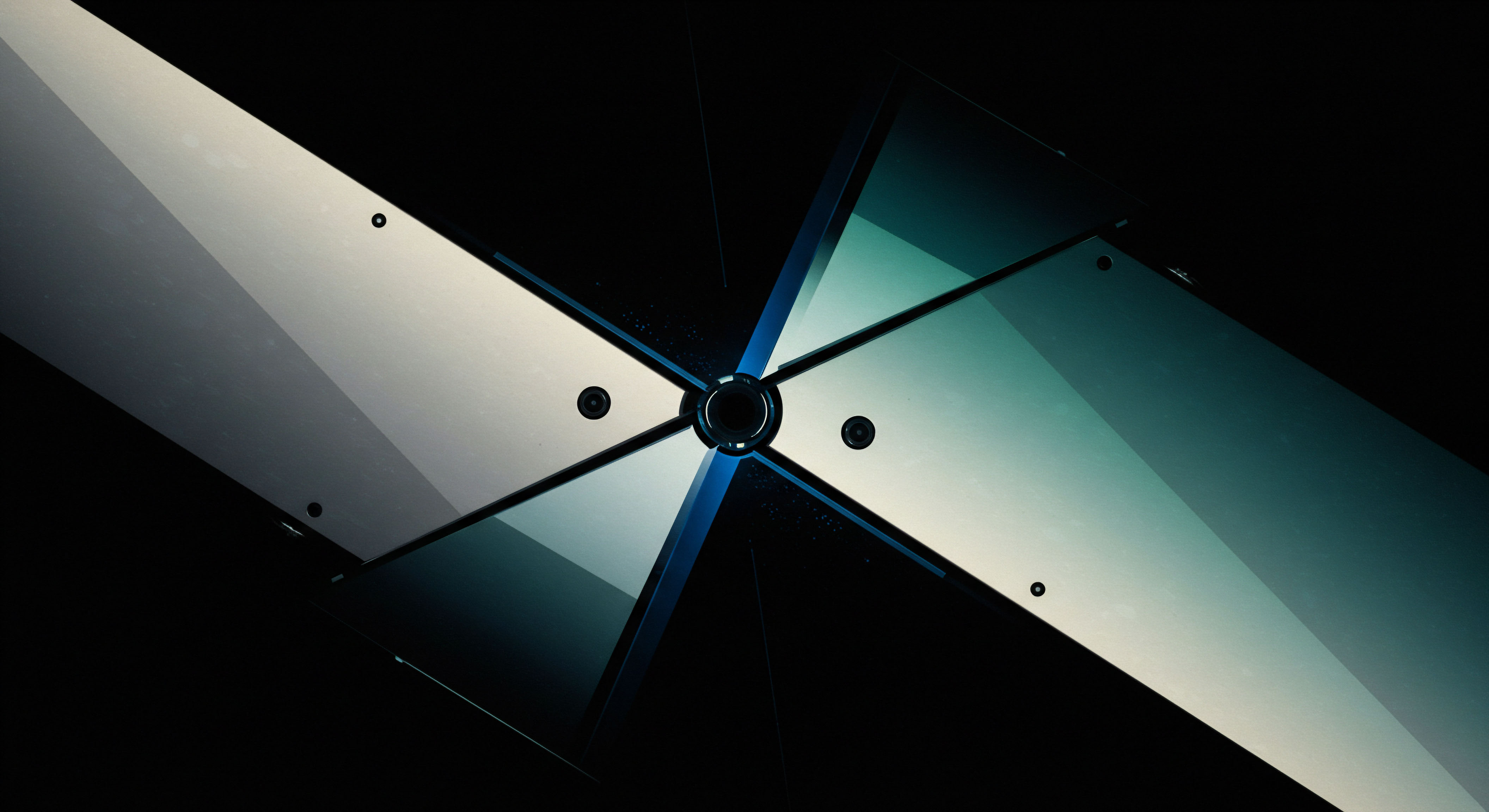

The immediate effect is the establishment of a panoramic view of the enterprise’s purchasing activities, where previously there existed only isolated snapshots. This systemic shift dissolves informational silos that naturally form in decentralized structures, where individual departments or business units manage their own sourcing events.

By unifying these communication streams, the procurement team gains an unprecedented level of control and visibility. Every interaction, every quote, and every contractual term becomes a data point in a larger, analyzable mosaic. This aggregation of information is the bedrock upon which strategic procurement is built. The team’s role begins to pivot from processing requisitions to architecting the supply base.

They are no longer simply facilitators of transactions but the primary custodians of the organization’s external spending power and supplier relationships. This consolidation of authority and information fundamentally alters the team’s capacity to act strategically, enabling them to leverage the organization’s full purchasing volume in negotiations and to implement consistent standards for quality and performance across the entire supplier ecosystem.

Centralizing RFP communications transforms a procurement team from a transactional service unit into a strategic organizational pillar.

This structural change also imposes a new level of discipline and standardization. In a decentralized model, RFP processes often vary widely, reflecting the disparate needs and practices of different departments. Centralization necessitates the development and enforcement of a single, optimized procurement methodology. The procurement team becomes the owner and enforcer of this standard, ensuring that every sourcing event adheres to best practices in terms of fairness, transparency, and rigor.

This uniformity streamlines the procurement cycle, reducing administrative overhead and accelerating the pace of sourcing. It also provides a clear, consistent interface for suppliers, which enhances the organization’s reputation as a professional and reliable partner. The transition, therefore, is one of both empowerment and responsibility, as the procurement team assumes a far more influential role in shaping the organization’s operational efficiency and financial performance.

Strategy

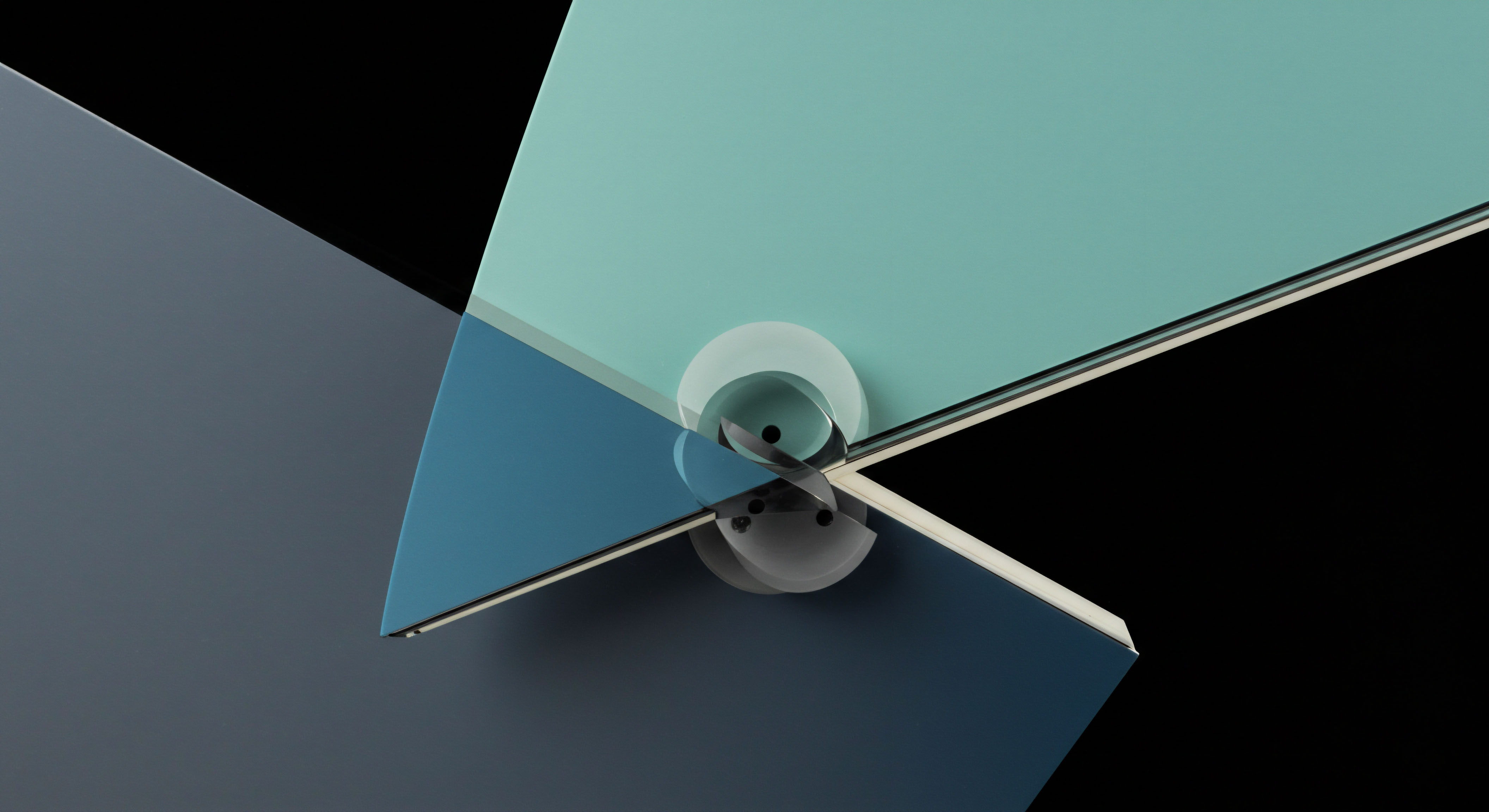

Adopting a centralized RFP communication model is a strategic maneuver that fundamentally reshapes the procurement function’s value proposition. The initiative extends well beyond a simple process adjustment; it represents a deliberate shift in how the organization leverages market intelligence, manages supplier relationships, and mitigates supply chain risk. The strategic impetus for this change is the recognition that fragmented purchasing power leads to value leakage through missed volume discounts, inconsistent contractual terms, and an inability to form deep, collaborative partnerships with critical suppliers. By channeling all RFP-related interactions through a central nexus, the procurement team is positioned to execute a cohesive, enterprise-wide sourcing strategy.

The Evolution from Tactical Buyer to Strategic Leader

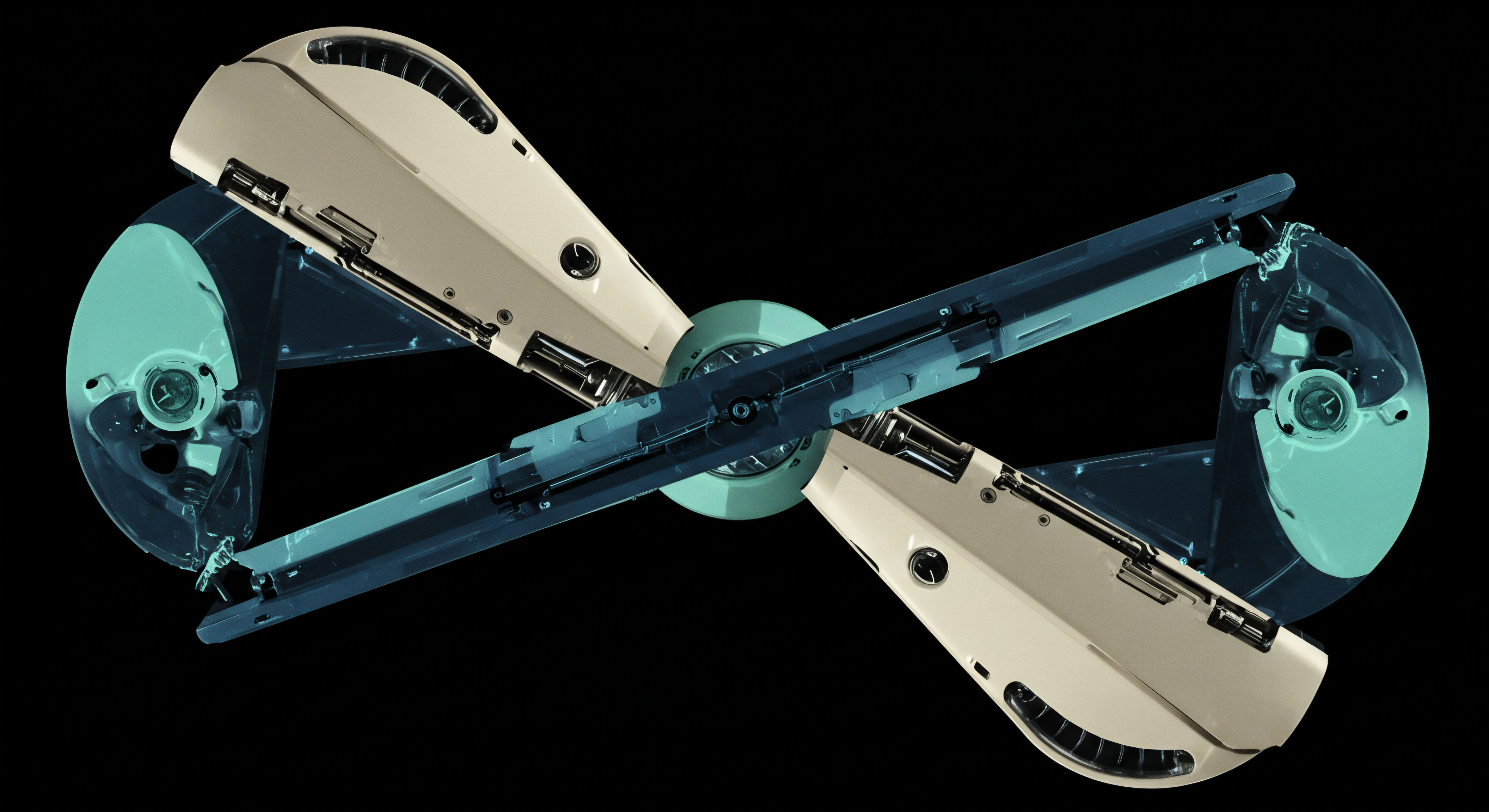

Centralization acts as a catalyst for a profound evolution in the roles within the procurement team. The focus shifts from the tactical execution of individual purchase orders to the strategic management of entire spend categories. Team members who once operated as generalist buyers are compelled to develop deep expertise in specific market sectors, becoming category managers who understand the nuances of their assigned supply markets. Their responsibilities expand to include market analysis, supplier development, and long-term strategic planning.

This elevated role requires a different set of competencies, moving from administrative efficiency to analytical acumen and strategic foresight. The procurement professional’s primary function becomes one of value creation, achieved through the strategic management of supplier capabilities and costs on a global scale.

The table below delineates the fundamental shift in roles and responsibilities that accompanies the centralization of RFP communications.

| Function | Decentralized Model (Tactical) | Centralized Model (Strategic) |

|---|---|---|

| Primary Focus | Processing purchase requisitions and fulfilling immediate departmental needs. | Managing total cost of ownership (TCO) across entire spend categories. |

| Supplier Interaction | Transactional and focused on individual RFP events. Relationships are often shallow and short-term. | Relationship-based and focused on long-term partnership and value co-creation. |

| Key Skills | Administrative processing, basic negotiation, and order management. | Data analysis, market intelligence, advanced negotiation, risk management, and supplier relationship management. |

| Performance Metrics | Purchase price variance (PPV) and requisition-to-order cycle time. | Category-level cost savings, supplier performance improvement, risk reduction, and innovation contributions. |

| Decision-Making | Reactive and driven by immediate internal client requests. | Proactive and driven by long-term strategic plans and data-driven insights. |

Cultivating a New Competency Matrix

The strategic reorientation of the procurement team necessitates a deliberate investment in developing new skills. A centralized model generates a vast amount of structured data from RFPs, creating a demand for professionals who can translate this data into actionable intelligence. The key competencies required for a strategic procurement function include:

- Advanced Data Analytics ▴ Team members must be proficient in analyzing spend data to identify savings opportunities, modeling total cost of ownership, and using predictive analytics to forecast price trends.

- Strategic Sourcing ▴ The ability to develop and execute comprehensive sourcing strategies for key categories, including conducting in-depth market research and supplier analysis.

- Supplier Relationship Management (SRM) ▴ Skills in segmenting the supplier base, developing collaborative partnerships with strategic suppliers, and managing supplier performance to drive continuous improvement.

- Complex Negotiation and Contract Management ▴ The capacity to lead complex negotiations for high-value contracts and to manage those contracts proactively to ensure compliance and value delivery.

- Risk Management ▴ The expertise to identify, assess, and mitigate a wide range of supply chain risks, from supplier financial instability to geopolitical disruptions.

Data as a Strategic Command Center

In a centralized model, the RFP process becomes a primary source of market intelligence. Every submitted proposal, every question from a supplier, and every negotiated price point contributes to a rich, historical database. This centralized repository of information allows the procurement team to move beyond anecdotal evidence and make decisions based on empirical data. They can benchmark pricing across suppliers and over time, track supplier performance against contractual obligations, and gain deep insights into market dynamics.

This data-driven approach enhances the credibility of the procurement team within the organization, allowing them to provide data-backed recommendations to senior leadership and to challenge internal stakeholders’ assumptions with hard evidence. The procurement function transforms into a command center for strategic intelligence, guiding the organization’s spending decisions with a level of insight that is impossible to achieve in a fragmented system.

Execution

The execution of a centralized RFP communication strategy requires a meticulously planned and phased approach. It is a transformational project that involves changes to processes, technology, and people. A successful implementation hinges on a clear operational playbook, the rigorous application of quantitative analysis, and the adoption of a robust technological architecture.

This transition is where strategic vision is translated into tangible operational control and measurable financial benefits. The procurement team must lead this charge, demonstrating the value of the new model through flawless execution and data-driven results.

The Operational Playbook for Centralization

Transitioning to a centralized RFP model involves a series of deliberate steps designed to ensure a smooth and effective rollout. This playbook provides a structured framework for managing the change and embedding the new operating model within the organization.

- Phase 1 ▴ Foundation and Design

- Stakeholder Alignment ▴ Conduct workshops with leaders from finance, IT, legal, and key business units to articulate the vision, benefits, and requirements of the centralized model. Secure executive sponsorship to champion the initiative.

- Process Mapping ▴ Document the existing decentralized RFP processes across the organization to identify variations, pain points, and inefficiencies.

- Design the Centralized Process ▴ Develop a single, standardized RFP process flow, from initial needs assessment to contract award. Define clear roles, responsibilities, and service level agreements (SLAs) for the central procurement team and business unit stakeholders.

- Technology Evaluation ▴ Assess the current technology landscape and identify the need for a dedicated e-procurement or RFP management platform. Develop a business case for technology investment if required.

- Phase 2 ▴ Building the Infrastructure

- Technology Implementation ▴ Select and implement the chosen technology platform. Configure the system to support the new standardized process, including templates for RFP documents, scoring matrices, and communication logs.

- Team Restructuring and Training ▴ Realign the procurement team around the new strategic roles (e.g. category managers, sourcing analysts). Develop and deliver a comprehensive training program covering the new processes, technology platform, and advanced skills like strategic sourcing and data analysis.

- Develop a Communication Plan ▴ Create a detailed plan for communicating the changes to all employees and key suppliers. The plan should explain the rationale for the change, the benefits, and the new procedures for initiating a sourcing request.

- Phase 3 ▴ Phased Rollout and Hypercare

- Pilot Program ▴ Launch the new model with a single, supportive business unit or a specific spend category. Use the pilot to test the process, technology, and team structure in a controlled environment.

- Gather Feedback and Refine ▴ Collect feedback from pilot participants and make necessary adjustments to the process and system before a full-scale rollout.

- Enterprise-Wide Deployment ▴ Roll out the centralized model to the rest of the organization in a phased manner. Provide “hypercare” support during the initial weeks of each phase to address issues quickly and ensure user adoption.

- Phase 4 ▴ Optimization and Continuous Improvement

- Performance Monitoring ▴ Establish a set of key performance indicators (KPIs) to track the success of the new model. Monitor metrics such as cost savings, cycle time reduction, and user satisfaction.

- Supplier Performance Management ▴ Leverage the centralized data to implement a formal supplier performance management program, including regular business reviews with strategic suppliers.

- Continuous Improvement ▴ Conduct regular reviews of the centralized process to identify opportunities for further optimization and efficiency gains.

Quantitative Modeling and Data Analysis

The value of centralization is most powerfully demonstrated through quantitative analysis. The consolidated data stream enables the procurement team to build sophisticated models for tracking performance and identifying opportunities. The table below illustrates a supplier performance scorecard, a critical tool enabled by centralized data collection.

| Metric | Weighting | Supplier A Score (1-5) | Supplier B Score (1-5) | Supplier C Score (1-5) | Data Source |

|---|---|---|---|---|---|

| Cost Competitiveness | 30% | 4 | 5 | 3 | Centralized RFP Bid Analysis |

| On-Time Delivery | 25% | 5 | 4 | 4 | ERP System Integration |

| Quality / Defect Rate | 25% | 4 | 3 | 5 | Quality Management System |

| Responsiveness & Communication | 10% | 3 | 5 | 4 | Centralized Communication Log |

| Innovation & Collaboration | 10% | 4 | 3 | 2 | Category Manager Assessment |

| Weighted Score | 100% | 4.10 | 4.15 | 3.65 | Calculated |

A centralized data framework allows procurement to shift from subjective supplier assessments to objective, data-driven performance management.

Predictive Scenario Analysis

Consider a multinational manufacturing firm, “GlobalCorp,” with five autonomous business units (BUs). Before centralization, each BU managed its own procurement, including RFPs for critical components. The procurement team in each BU operated independently, leading to significant inefficiencies. For instance, the company was purchasing similar electronic components from three different suppliers at varying prices, with an average unit cost of $5.25.

The lack of visibility meant that no single person at GlobalCorp knew the total spend on this category, which amounted to over $10 million annually across all BUs. Supplier relationships were transactional, and contract terms were inconsistent. The procurement professionals spent most of their time on administrative tasks, processing paperwork and responding to urgent requests from their local stakeholders. There was no overarching strategy, no leverage of the company’s scale, and significant value leakage.

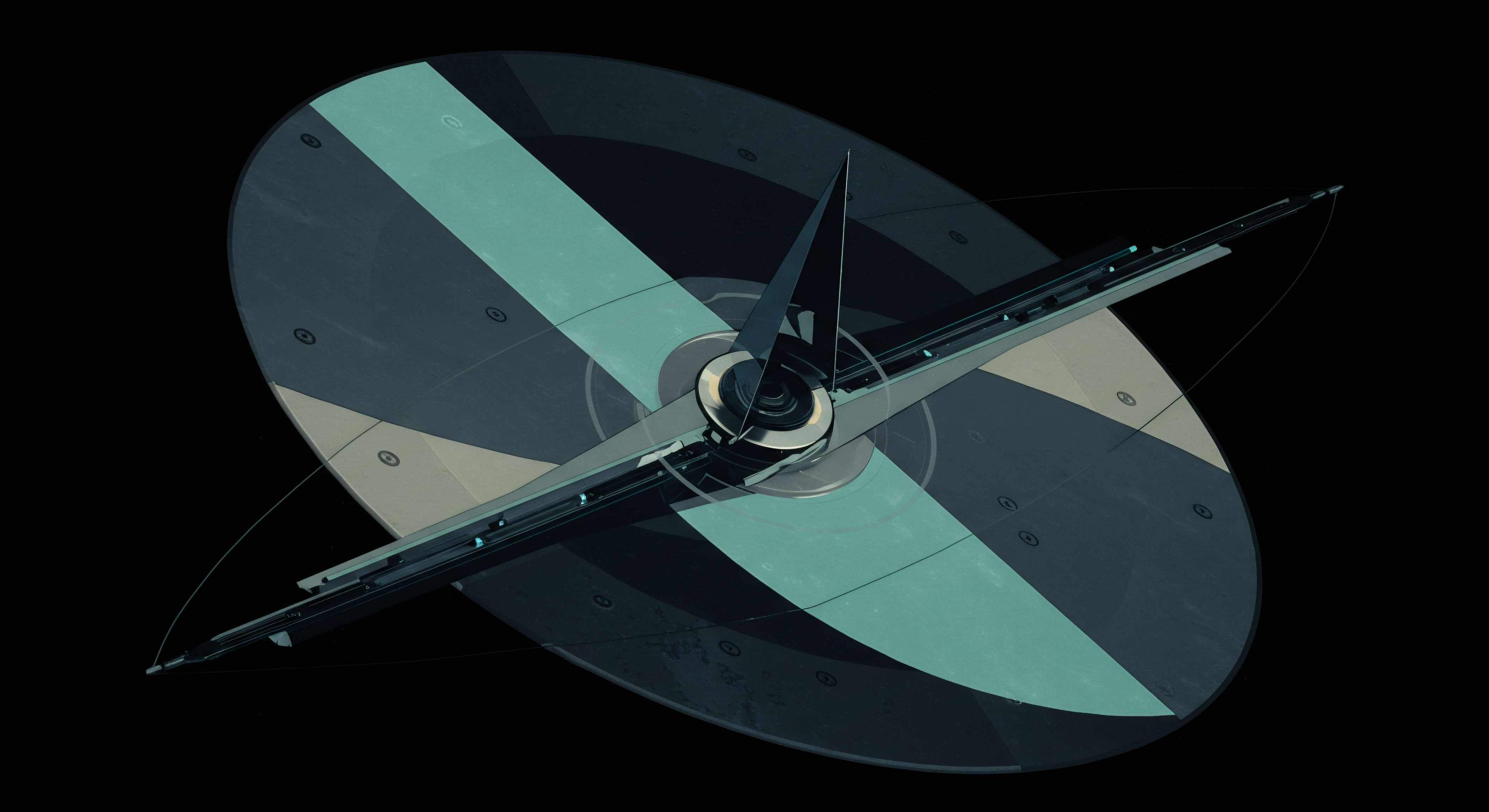

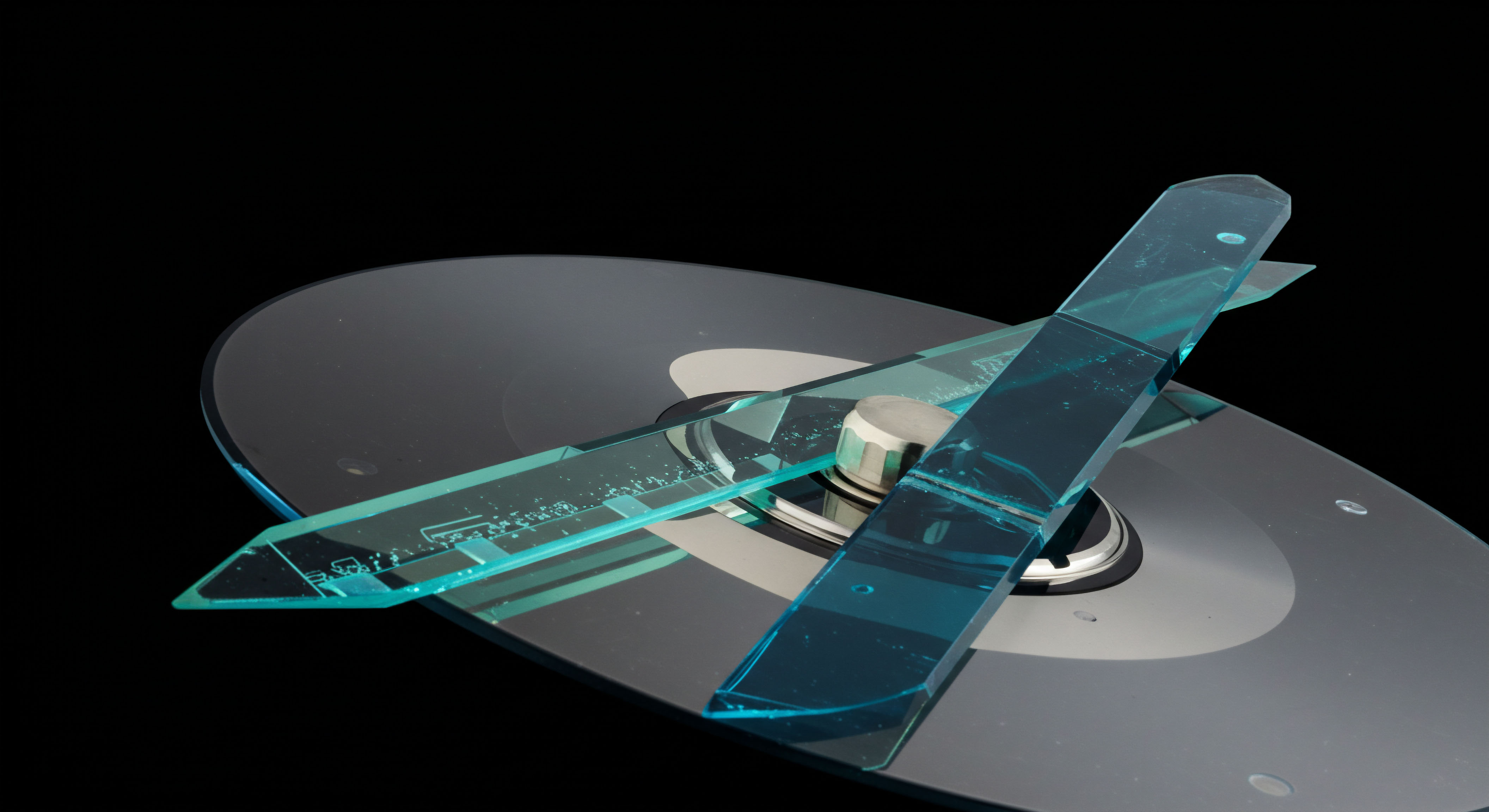

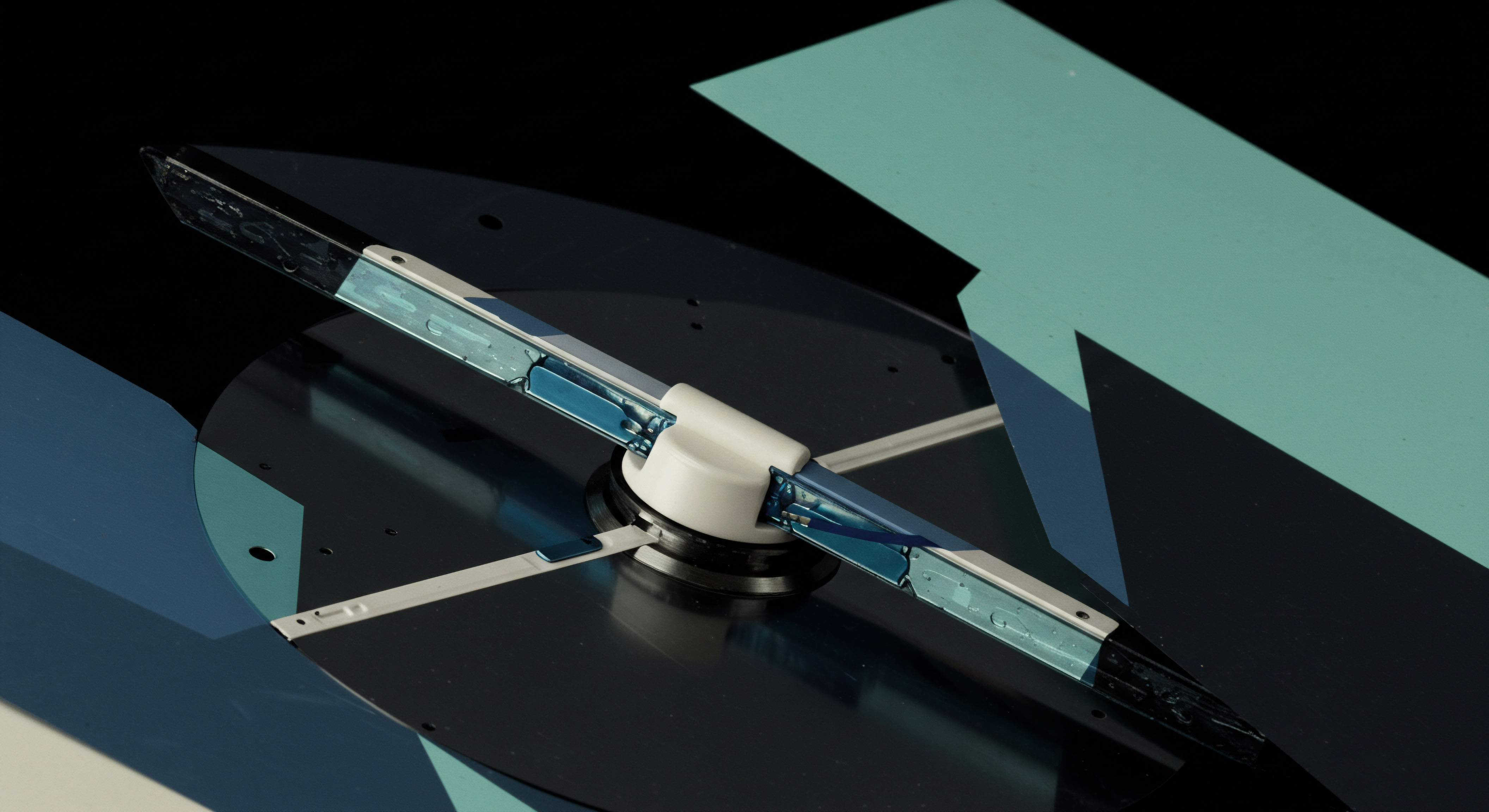

The newly appointed Chief Procurement Officer (CPO) initiated a project to centralize all strategic sourcing activities, starting with RFP communications. The first step was to implement a cloud-based e-sourcing platform to serve as the single portal for all RFP activities. A central procurement team was established, with category managers assigned to key areas like electronics, logistics, and professional services. The team’s first major initiative was to run a consolidated RFP for the electronic components previously sourced independently by the BUs.

The category manager began by using the new platform to gather all historical spend data, discovering the full $10 million scope of the category. This data alone provided a powerful new perspective. Armed with this information, the category manager conducted a thorough market analysis and identified a long list of ten potential suppliers, including the three incumbents.

A single, comprehensive RFP was issued through the e-sourcing portal to all ten suppliers. The RFP included detailed specifications, volume forecasts for the entire organization, and a standardized template for pricing. For the first time, suppliers were competing for the entire volume of GlobalCorp’s business in this category. The centralized communication feature of the platform was critical during this phase.

All supplier questions were submitted through the portal and the answers were broadcast to all participants simultaneously, ensuring a fair and transparent process. This eliminated the risk of one supplier receiving information that others did not, a common problem in the previous decentralized model.

The results of the consolidated RFP were transformative. The increased competition and the leverage of the full $10 million spend resulted in a significant reduction in unit cost. The winning bid came in at an average of $4.10 per unit, a 22% reduction from the previous average. This single sourcing event generated over $2.2 million in annual savings.

The benefits, however, went far beyond cost reduction. The centralized process allowed GlobalCorp to award the business to a single, highly capable supplier. This consolidation enabled the negotiation of a multi-year strategic partnership agreement that included terms for supplier-held inventory, joint innovation workshops, and a continuous improvement program. The procurement category manager’s role shifted from a tactical buyer to a strategic relationship manager, responsible for maximizing the value of this new partnership.

The transition was not without its challenges. Initially, there was resistance from the business units, who were accustomed to their autonomy and existing supplier relationships. The CPO and the central procurement team had to conduct extensive roadshows and training sessions to get buy-in from local stakeholders. They used the data from the pilot electronics RFP to build a powerful business case, demonstrating the tangible financial benefits of the new model.

The success of this first project helped to overcome the initial skepticism and build momentum for centralizing other spend categories. Over the next two years, GlobalCorp rolled out the centralized model across all its major spend areas, achieving over $30 million in annualized savings and transforming its procurement function from a fragmented, administrative cost center into a unified, strategic powerhouse that delivered a significant competitive advantage.

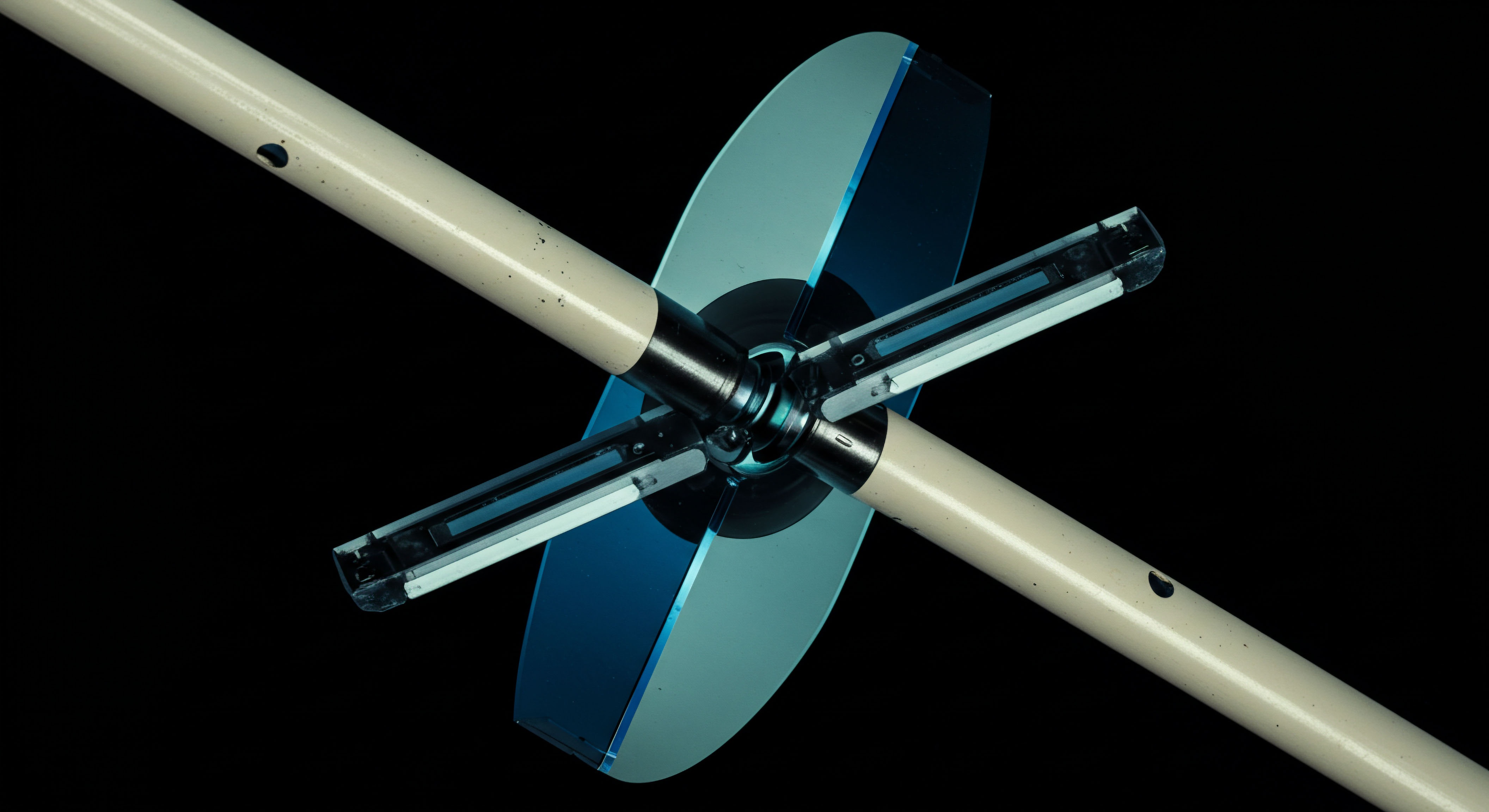

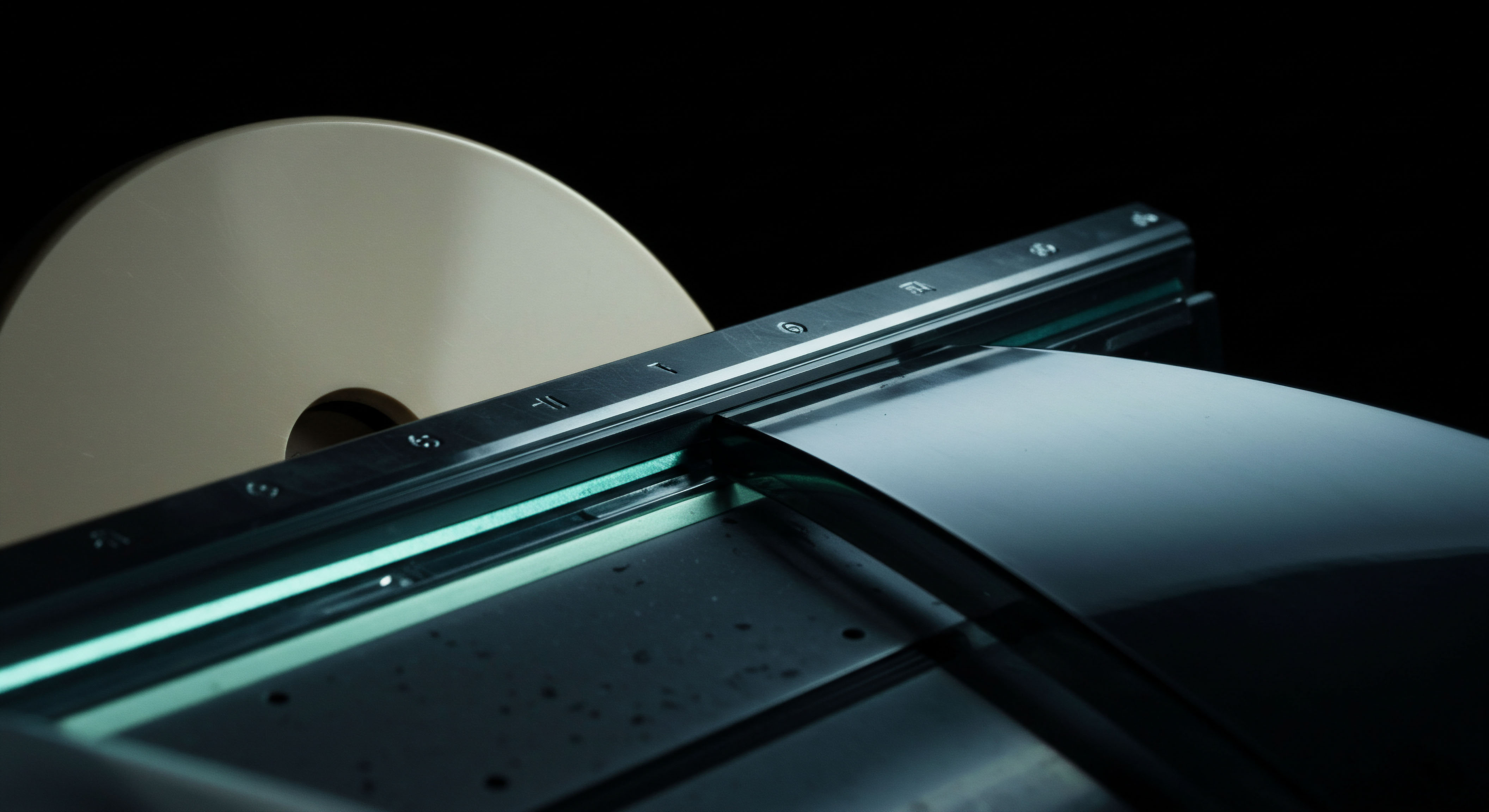

System Integration and Technological Architecture

The execution of a centralized strategy is critically dependent on a robust technological foundation. An integrated procurement technology suite serves as the central nervous system for the entire process, enabling the efficiency, visibility, and data analysis that the model promises. The core components of this architecture include:

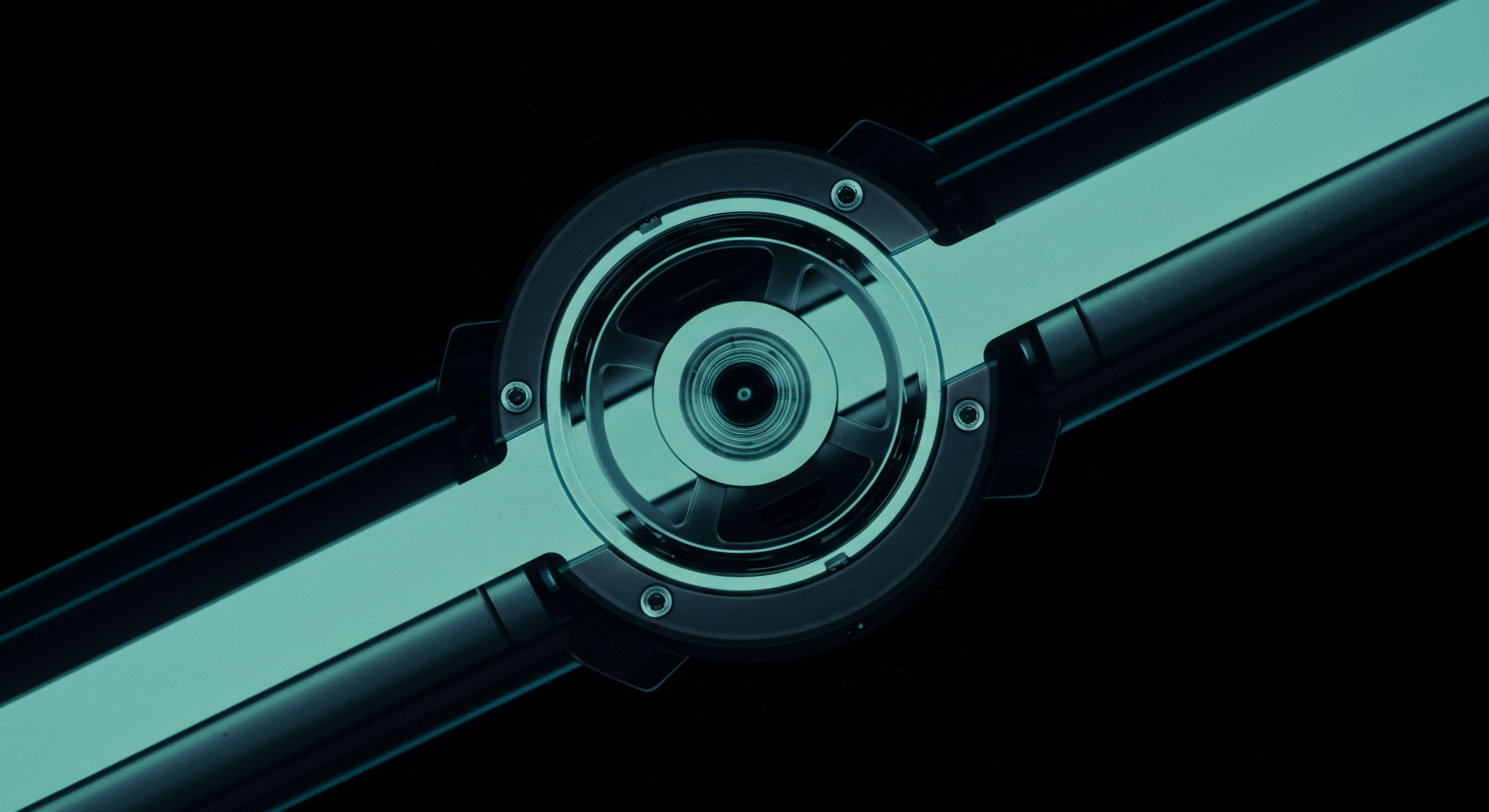

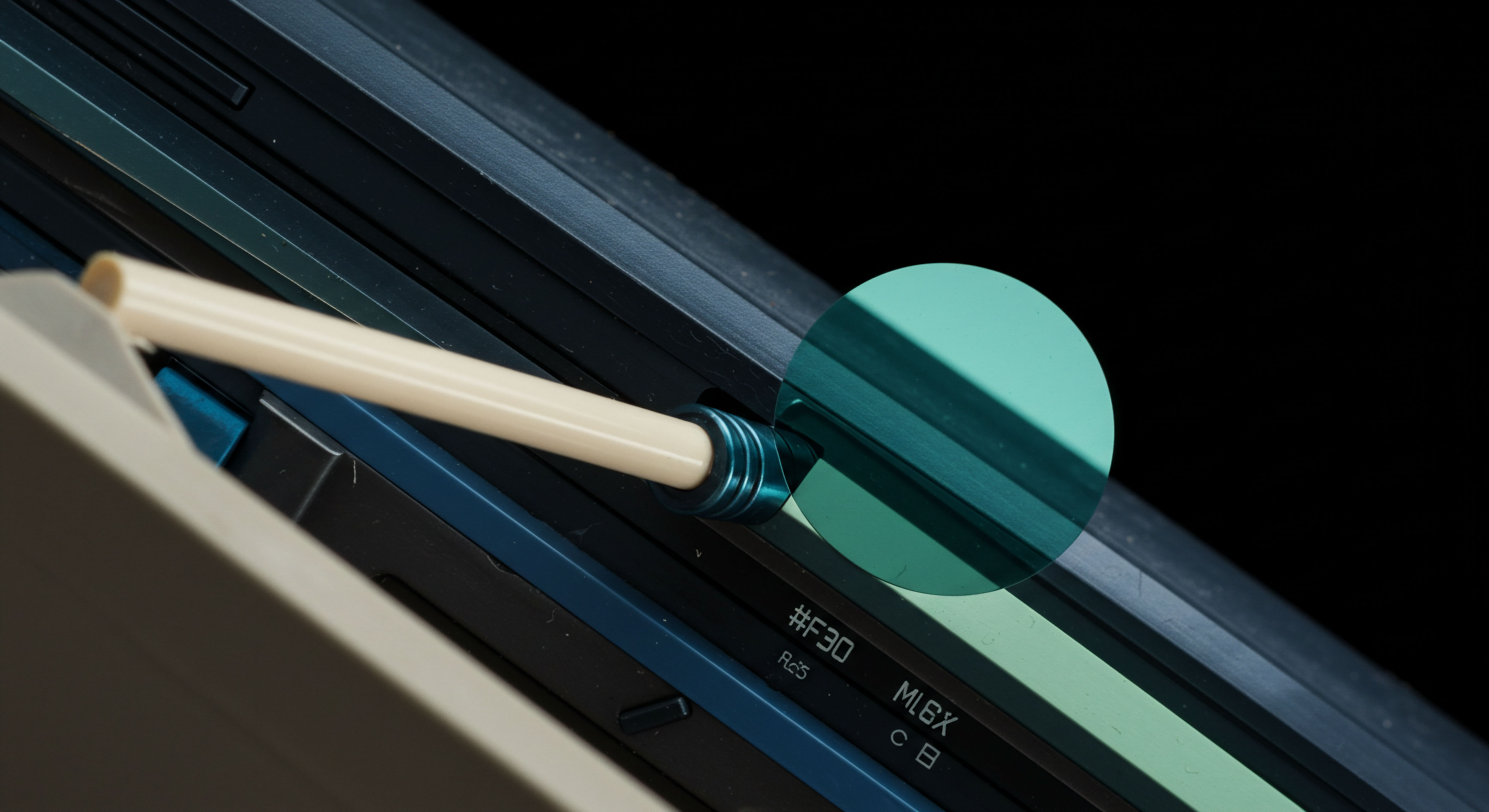

- E-Sourcing/RFP Management Platform ▴ This is the heart of the centralized communication model. Key features include RFP creation templates, a secure supplier portal for bid submission, a centralized communication log for all Q&A, automated scoring and side-by-side response comparison tools.

- Contract Lifecycle Management (CLM) System ▴ This system stores all contracts in a central, searchable repository. It integrates with the RFP platform to ensure that the terms negotiated during the sourcing event are accurately reflected in the final contract.

- Spend Analytics Tool ▴ This tool aggregates spend data from across the organization, providing the visibility needed to identify sourcing opportunities and track compliance with preferred supplier programs.

- Enterprise Resource Planning (ERP) Integration ▴ Seamless integration with the company’s ERP system is essential for connecting the sourcing process with downstream procure-to-pay activities, ensuring that negotiated savings are realized in actual spend.

References

- Monczka, Robert M. et al. Purchasing and Supply Chain Management. Cengage Learning, 2015.

- Baily, Peter, et al. Procurement, Principles & Management. Pearson Education, 2015.

- Van Weele, Arjan J. Purchasing and Supply Chain Management ▴ Analysis, Strategy, Planning and Practice. Cengage Learning, 2018.

- Handfield, Robert B. “The Role of Strategic Sourcing in Modern Procurement.” Journal of Business Logistics, vol. 37, no. 1, 2016, pp. 3-5.

- Tassabehji, Rana, and Andrew Moorhouse. “The Changing Role of Procurement ▴ Developing Professional Effectiveness.” Journal of Purchasing and Supply Management, vol. 14, no. 1, 2008, pp. 55-68.

- Schiele, Holger. “Accessing and Exploiting Supplier Know-How ▴ A Conceptual Model of Supplier-Induced Innovation.” Journal of Supply Chain Management, vol. 48, no. 2, 2012, pp. 52-73.

- Gelderman, Cees J. and Arjan J. Van Weele. “Handling Measurement Issues and Strategic Directions in Kraljic’s Purchasing Portfolio Model.” Journal of Purchasing and Supply Management, vol. 11, no. 5-6, 2005, pp. 207-16.

Reflection

A New Operational Bearing

The centralization of RFP communications is a foundational shift that redefines a procurement team’s purpose within an organization. It is the point where the function transitions from a cost center focused on administrative processing to a strategic entity dedicated to value engineering the supply chain. This journey requires more than new software or redesigned process flows; it demands a new mindset. It asks procurement professionals to see their role not as gatekeepers of spend, but as architects of a competitive advantage built upon a network of high-performing, collaborative supplier partnerships.

Reflecting on this transformation invites a critical assessment of your own organization’s procurement posture. Where does the function currently reside on the spectrum from tactical to strategic? Does the team possess the analytical capabilities and the business acumen to lead the organization in complex sourcing decisions? The answers to these questions reveal the potential for unlocking significant value that may be latent within your supply chain.

The path forward involves embracing data, cultivating new skills, and building the credibility to guide the enterprise’s most critical purchasing decisions. It is a challenging but ultimately rewarding evolution that solidifies procurement’s role as an indispensable driver of organizational success.

Glossary

Centralized Rfp

Supply Chain

Rfp Communications

Centralized Model

Total Cost of Ownership

Strategic Sourcing

Supplier Relationship Management

Supplier Performance

E-Procurement

Data Analysis

Contract Lifecycle Management