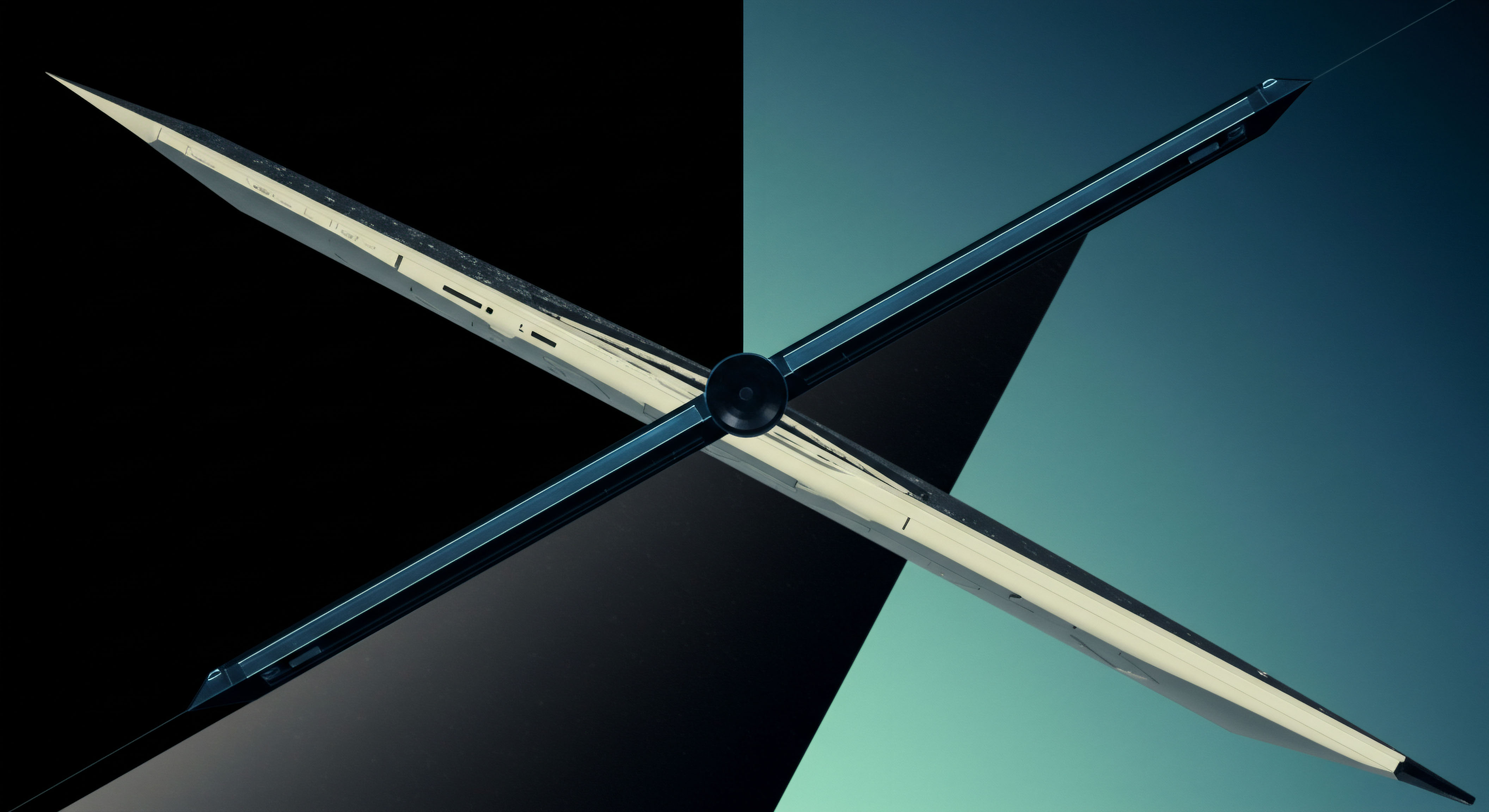

Concept

The Procurement Function as a Unified System

The question of how supplier relationship management affects procurement efficiency is often answered with discussions of collaboration and partnership. While accurate, this view is incomplete. A more precise understanding positions Supplier Relationship Management (SRM) as the core operating system for the entire procurement value chain. It is a disciplined, data-centric methodology designed to standardize interactions, mitigate information asymmetry, and convert supplier capabilities into a quantifiable corporate asset.

The efficiency of a procurement department is a direct output of the sophistication of its underlying SRM protocol. A mature SRM implementation redefines procurement from a series of discrete, transactional events into a cohesive, intelligent system engineered for value preservation and creation.

At its heart, procurement is an exercise in managing uncertainty. This uncertainty manifests as supply disruption, price volatility, quality variance, and geopolitical instability. An unstructured approach to procurement, where each sourcing event is treated in isolation, amplifies this uncertainty. Each transaction becomes a new point of potential failure.

SRM provides the systemic antidote. By establishing clear, tiered protocols for communication, performance measurement, and risk assessment, it creates a predictable and resilient operational environment. Suppliers cease to be external variables and become integrated nodes within a managed network. The efficiency gains observed are not merely incidental benefits of good rapport; they are the engineered outcomes of a well-designed system.

A sophisticated SRM program transforms the supply base from an external variable into a controlled, integrated network, directly enhancing the predictability and efficiency of procurement operations.

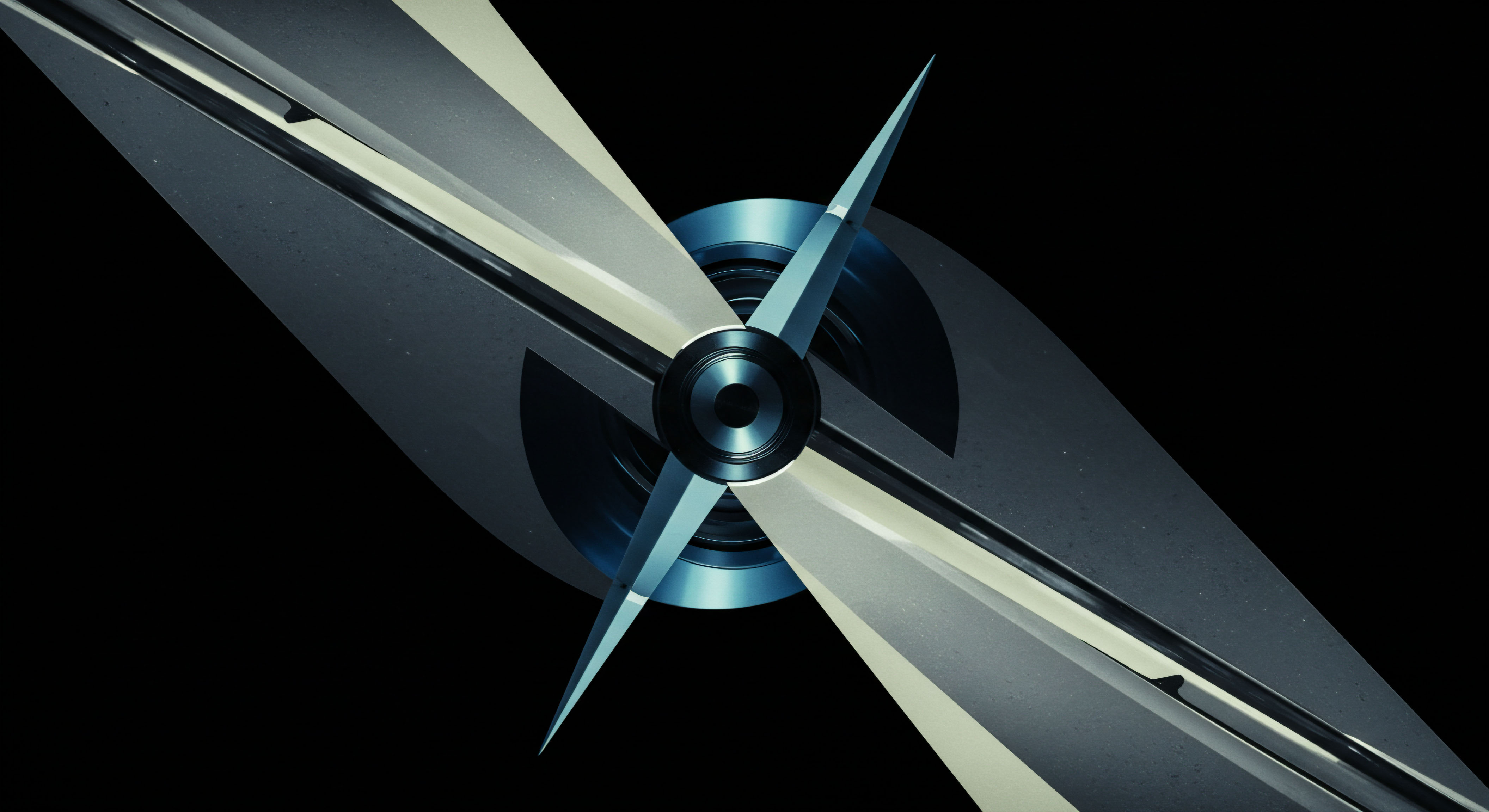

Information Asymmetry and Systemic Friction

A primary source of inefficiency in any procurement process is information asymmetry ▴ the condition where the supplier possesses more, or better, information than the buyer. This imbalance can pertain to cost structures, production capacity, market conditions, or impending disruptions. Without a structured SRM system, each negotiation and purchase order is conducted across this informational divide, creating friction that manifests as higher costs, suboptimal terms, and increased risk. Procurement teams spend an inordinate amount of resources attempting to bridge this gap on a case-by-case basis, a fundamentally inefficient allocation of capital and expertise.

SRM directly addresses this systemic friction by creating dedicated channels for high-fidelity information exchange. For strategic suppliers, this involves joint business planning, shared technology roadmaps, and transparent cost modeling. For operational partners, it means standardized performance dashboards and automated data feeds on inventory levels and delivery schedules.

This structured flow of information reduces the cognitive load on procurement professionals, allowing them to shift their focus from tactical data gathering to strategic analysis and decision-making. The result is a procurement process characterized by reduced cycle times, fewer errors, and a lower total cost of ownership, all stemming from the systematic reduction of informational friction.

From Transactional Exchanges to Value Co-Creation

The traditional procurement model is inherently transactional. It is optimized for securing the lowest possible price for a given specification in a single event. This model, however, often destroys long-term value.

It disincentivizes supplier innovation, discourages investment in the buyer’s business, and creates an adversarial dynamic that is brittle in the face of market shocks. Efficiency in this paradigm is narrowly defined as purchase price variance, ignoring the broader, more significant costs associated with poor quality, late deliveries, and a lack of supplier-led innovation.

Implementing a robust SRM system facilitates a deliberate shift from this transactional model to one of value co-creation. By segmenting the supplier base, an organization can identify partners with the potential for deep collaboration. With these strategic suppliers, the objective changes from cost minimization to value maximization. This can take many forms ▴ joint process improvements that reduce waste for both parties, collaborative product design that accelerates time-to-market, or shared investments in technology that create a mutual competitive advantage.

Procurement efficiency, in this context, is redefined. It is measured not just by cost savings, but by revenue enablement, risk reduction, and the generation of intellectual property. This elevated state is only achievable through the structured, long-term perspective that a formal SRM system provides.

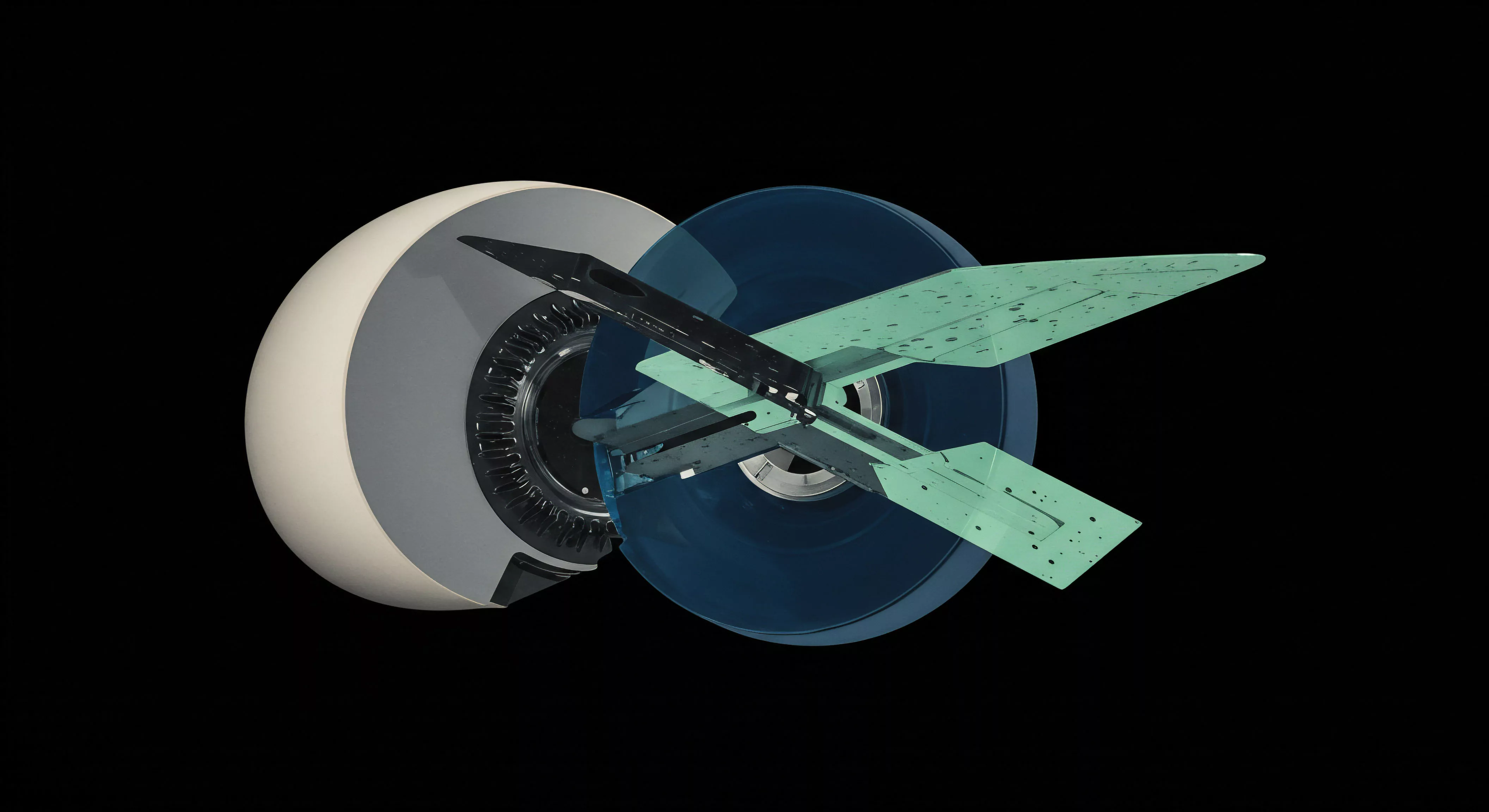

Strategy

Designing the Supplier Segmentation Matrix

The foundational act of strategic SRM is the segmentation of the supply base. A uniform approach to managing all suppliers is a recipe for profound inefficiency, wasting valuable resources on transactional relationships while underinvesting in strategic ones. The objective is to create a differentiated management strategy where the level of engagement is precisely calibrated to the supplier’s potential impact on the organization’s performance.

The Kraljic Matrix remains a seminal model for this task, plotting suppliers on two axes ▴ profit impact and supply risk. This analysis yields four distinct supplier categories, each demanding a unique strategic posture.

- Strategic Items (High Profit Impact, High Supply Risk) ▴ These are the most critical suppliers, forming the core of the SRM program. The strategy here is one of deep collaboration and partnership. It involves executive-level engagement, joint strategic planning, and the creation of long-term agreements. The goal is to build a resilient, co-dependent relationship that fosters mutual growth and innovation. Performance metrics extend beyond cost and delivery to include joint R&D outcomes and shared market success.

- Leverage Items (High Profit Impact, Low Supply Risk) ▴ For these suppliers, the organization holds a position of strength. The market has ample capacity, and switching costs are relatively low. The procurement strategy focuses on optimizing value through competitive tension. This involves frequent negotiations, volume bundling, and the use of e-auctions to drive down prices. The relationship is professional but transactional, with a primary focus on maximizing commercial advantage.

- Bottleneck Items (Low Profit Impact, High Supply Risk) ▴ These suppliers represent a significant source of potential disruption. While their financial impact may be small, the lack of viable alternatives makes the supply chain vulnerable. The strategy here is centered on assuring supply continuity and reducing dependence. This may involve holding safety stock, seeking out alternative materials or technologies, and maintaining a good working relationship to ensure the organization is a customer of choice. The key is risk mitigation.

- Non-Critical Items (Low Profit Impact, Low Supply Risk) ▴ These items are the least important from a strategic perspective. The primary goal is to minimize the administrative overhead associated with their procurement. The strategy involves process automation, the use of purchasing cards (P-Cards), and delegating purchasing authority to end-users through catalogues. The relationship is purely transactional, and the focus is on process efficiency.

Implementing this segmentation is the first step in transforming procurement from a reactive to a strategic function. It provides a clear blueprint for allocating resources and tailoring engagement models, ensuring that maximum effort is directed where it can generate the greatest return.

A well-defined supplier segmentation strategy is the critical first step in allocating procurement resources effectively, moving the function from a purely tactical role to a strategic one.

Constructing a Tiered Governance Framework

Once the supply base is segmented, the next strategic imperative is to build a corresponding governance structure. A tiered governance model ensures that the right people are having the right conversations with the right suppliers at the right frequency. Without this structure, strategic intent dissolves into chaotic execution. The model typically consists of several layers of engagement, each with a defined purpose, set of participants, and meeting cadence.

This is not a bureaucratic exercise. It is a system for operationalizing strategy.

A typical tiered model might look like this:

- Executive Business Review (Annual) ▴ Reserved for the most strategic partners. This meeting involves C-level executives from both the buying organization and the supplier. The agenda focuses on long-term strategic alignment, joint investment decisions, and a review of the overall partnership health. It sets the tone and direction for the relationship for the coming year.

- Quarterly Business Review (Quarterly) ▴ Involves senior management from both sides. This forum is used to review performance against key metrics, discuss ongoing projects, identify and resolve systemic issues, and explore new opportunities for collaboration. It is the primary vehicle for managing the strategic relationship.

- Operational Performance Review (Monthly) ▴ Conducted by category managers and their supplier counterparts. This meeting is tactical in nature, focusing on day-to-day performance, resolving delivery or quality issues, and managing forecasts and inventory levels. It ensures the smooth functioning of the operational supply chain.

- Automated Reporting and Alerts (Continuous) ▴ For non-critical and leverage suppliers, human interaction is minimized. Governance is handled through automated systems that track performance against contracts and trigger alerts when deviations occur. This allows procurement professionals to manage a large number of suppliers by exception.

This structured approach to governance ensures that communication is purposeful and efficient. It prevents high-level strategic discussions from being derailed by minor operational issues and ensures that tactical problems are resolved quickly before they can escalate. It is the architecture of effective communication.

Developing a Robust Performance Management System

A cornerstone of any SRM strategy is a robust performance management system. The adage “you can’t manage what you can’t measure” is particularly true in procurement. An effective performance management system serves two primary functions ▴ it ensures that suppliers are meeting their contractual obligations, and it provides the objective data needed to drive continuous improvement and collaborative initiatives. The design of this system must be deliberate, with metrics carefully chosen to reflect the strategic importance of the supplier segment.

A balanced scorecard approach is often the most effective way to structure supplier performance measurement. This prevents the common mistake of focusing excessively on a single metric, such as cost, at the expense of others that are equally important for long-term value. The scorecard should be tailored to the supplier segment, but typically includes a mix of quantitative and qualitative measures across several key dimensions.

| Dimension | Strategic Suppliers | Leverage Suppliers | Bottleneck Suppliers | Non-Critical Suppliers |

|---|---|---|---|---|

| Cost | Total Cost of Ownership (TCO), Joint Cost Reduction Initiatives | Purchase Price Variance (PPV), Competitive Benchmarking | Price Stability, Cost Transparency | Price Compliance to Catalogue |

| Quality | First Pass Yield, Customer Defect Rates, Six Sigma Collaboration | Defects Per Million (DPM), Conformance to Specification | Consistency of Quality, Zero Defects | Acceptable Quality Level (AQL) |

| Delivery | On-Time In-Full (OTIF), Lead Time Reduction Projects | OTIF, Order Cycle Time | Delivery Reliability, Supply Assurance | On-Time Delivery |

| Innovation | New Product Introduction (NPI) Contribution, Technology Sharing | Process Improvement Suggestions | Alternative Material Proposals | Not Applicable |

| Relationship | Executive Alignment Score, 360-Degree Feedback | Responsiveness, Ease of Doing Business | Willingness to Share Information | Transactional Efficiency |

The data from this scorecard becomes the factual basis for all supplier review meetings. It removes subjectivity and emotion from performance discussions, allowing for a more productive and forward-looking dialogue. When performance gaps are identified, they can be addressed through joint corrective action plans.

When performance is strong, it can be recognized and rewarded. This data-driven approach is fundamental to building a high-performing, resilient, and efficient supply base.

Execution

The Operational Playbook for SRM Implementation

The translation of SRM strategy into tangible results hinges on a meticulously planned and executed implementation. This is a change management program as much as it is a procurement initiative. It requires dedicated resources, clear milestones, and a phased rollout to build momentum and demonstrate early wins. The following represents a structured, multi-phase playbook for embedding a world-class SRM system into the operational fabric of an organization.

Phase 1 ▴ Foundation and Mobilization (Months 1-3)

This initial phase is about establishing the mandate and building the necessary infrastructure for the program.

- Secure Executive Sponsorship ▴ The program must have visible and vocal support from the highest levels of the organization, typically the Chief Procurement Officer (CPO) and Chief Financial Officer (CFO). This sponsorship is essential for securing resources and overcoming organizational inertia.

- Form a Cross-Functional Team ▴ SRM is not solely a procurement activity. The core team should include representatives from procurement, operations, engineering, quality, and finance to ensure all perspectives are considered and to build broad ownership of the program.

- Develop the Business Case ▴ A clear and compelling business case must be articulated, outlining the expected benefits in terms of cost reduction, risk mitigation, and value creation. This should be supported by a baseline analysis of current procurement performance.

- Conduct Initial Supply Base Analysis ▴ Perform a preliminary spend analysis to get a high-level understanding of the current supply base. This data will be crucial for the segmentation work in the next phase.

Phase 2 ▴ Segmentation and Strategy Development (Months 4-6)

With the foundation in place, the focus shifts to detailed analysis and the development of tailored management strategies.

- Detailed Supplier Segmentation ▴ Apply the Kraljic Matrix or a similar framework to the entire managed spend. This is an analytical exercise that requires clean data and cross-functional input to accurately assess both profit impact and supply risk.

- Define Governance Models ▴ For each supplier segment, define the specific governance structure, including meeting cadence, participants, and standard agendas.

- Design Balanced Scorecards ▴ Develop the specific Key Performance Indicators (KPIs) that will be used to measure supplier performance in each segment. It is vital to gain consensus on these metrics from the cross-functional team.

- Select Pilot Program ▴ Choose a specific commodity or business unit for a pilot implementation. This allows the team to test and refine the new processes on a smaller scale before a full-scale rollout.

Phase 3 ▴ Pilot and Refinement (Months 7-12)

This phase is about testing the system in a real-world environment and making the necessary adjustments.

- Launch Pilot Program ▴ Roll out the new segmentation, governance, and performance management processes for the selected pilot group. This includes communicating the new approach to the affected internal stakeholders and suppliers.

- Conduct First Review Cycles ▴ Execute the first few cycles of the new governance meetings (e.g. the first Quarterly Business Review for a strategic pilot supplier).

- Gather Feedback and Measure Results ▴ Solicit feedback from all participants and track the performance of the pilot group against the baseline. Identify what is working well and what needs to be improved.

- Refine the Playbook ▴ Update the process documents, scorecard metrics, and governance models based on the learnings from the pilot.

Phase 4 ▴ Full-Scale Rollout and Continuous Improvement (Month 13 Onwards)

The final phase involves expanding the program across the entire organization and embedding it into the culture.

- Develop a Phased Rollout Plan ▴ Create a detailed plan for extending the SRM program to the rest of the organization, typically on a commodity-by-commodity or business-unit-by-business-unit basis.

- Invest in Technology ▴ Implement or upgrade the necessary technology platforms (e.g. SRM software, supplier portals, data analytics tools) to support the program at scale.

- Train the Organization ▴ Conduct comprehensive training for all procurement professionals and other relevant stakeholders on the new SRM processes and their roles within them.

- Establish a Center of Excellence ▴ Create a central team responsible for maintaining the integrity of the SRM program, driving continuous improvement, and sharing best practices across the organization.

Quantitative Modeling and Data Analysis

The effectiveness of an SRM system is directly proportional to the quality of the data that underpins it. Moving beyond subjective assessments to rigorous quantitative analysis is what separates a world-class procurement function from an average one. Two key analytical models form the quantitative backbone of a mature SRM program ▴ Total Cost of Ownership (TCO) and a data-driven Supplier Risk Scorecard.

The challenge with TCO is often one of completeness. It is simple to calculate the purchase price, but much harder to systematically capture all the other relevant costs. This requires a disciplined process of identifying cost drivers, gathering data from multiple systems (ERP, quality management, logistics), and constructing a model that is both comprehensive and practical to maintain. We must grapple with the allocation of internal costs, such as the cost of processing a defective part or the cost of expediting a late shipment.

The initial reaction is often that this data is too difficult to obtain. A more constructive view is that the process of building the model itself reveals the hidden costs of poor supplier performance, creating a powerful business case for improvement.

A procurement function’s maturity can be measured by its ability to look beyond purchase price and quantify the total cost of ownership for its key supplies.

Total Cost of Ownership (TCO) Modeling

The TCO model shifts the focus from the purchase price to the total cost incurred over the entire lifecycle of a product or service. This provides a far more accurate basis for comparing suppliers and making sourcing decisions.

| Cost Element | Supplier A | Supplier B | Data Source |

|---|---|---|---|

| Purchase Price (per unit) | $10.00 | $9.50 | Purchase Order System |

| Inbound Freight (per unit) | $0.50 | $0.75 | Logistics System |

| Inventory Holding Cost (per unit/year) | $1.00 | $1.20 | ERP/Finance Model |

| Quality Cost (per unit) | $0.10 (1% defect rate $10 rework cost) | $0.50 (4% defect rate $12.50 rework cost) | Quality Management System |

| Late Delivery Cost (per unit) | $0.05 (1% late $5 expediting cost) | $0.75 (10% late $7.50 expediting cost) | ERP/Operations Data |

| Total Cost of Ownership (per unit) | $11.65 | $12.70 | – |

In this simplified model, Supplier B, despite having a 5% lower purchase price, has a 9% higher Total Cost of Ownership due to poorer performance in quality and delivery. This type of analysis fundamentally changes the sourcing decision and provides a clear, quantitative justification for selecting the higher-priced but better-performing supplier.

Supplier Risk Scorecard

A supplier risk scorecard aggregates multiple risk indicators into a single, quantifiable score. This allows for the objective comparison of risk levels across the supply base and provides an early warning system for potential disruptions.

The scorecard should include a weighted average of several risk categories:

- Financial Risk (30% Weight) ▴ This is assessed using data from financial information providers (e.g. Dun & Bradstreet). Key metrics include the supplier’s credit rating, debt-to-equity ratio, and profitability trends.

- Operational Risk (40% Weight) ▴ This is derived from the supplier’s performance data. Key metrics include on-time delivery, quality defect rates, and lead time variability. It also includes an assessment of the supplier’s own supply chain vulnerabilities.

- Geopolitical and Compliance Risk (30% Weight) ▴ This assesses the risk associated with the supplier’s location and their compliance with relevant regulations (e.g. environmental, labor laws). This data is often sourced from third-party risk intelligence services.

Each supplier is scored on a scale of 1-100 for each category, and a weighted average is calculated to produce an overall risk score. This allows procurement to create a “heat map” of the supply base, identifying high-risk suppliers that require immediate mitigation actions, such as developing a second source or increasing safety stock.

Predictive Scenario Analysis a Case Study

To illustrate the tangible impact of a mature SRM system, consider the case of “AutoCorp,” a mid-sized automotive component manufacturer. AutoCorp had invested heavily in building a tiered SRM program for its key commodities, particularly for the microcontrollers that were essential to its flagship product.

Their primary microcontroller supplier, “ChipOne,” was designated as a strategic partner. This meant they had a comprehensive governance structure in place, including quarterly business reviews, shared demand forecasts, and a transparent performance scorecard. As part of their SRM process, AutoCorp’s commodity manager had worked with ChipOne to map out ChipOne’s own supply chain, identifying that a critical sub-component was sourced from a single factory in a region prone to seismic activity.

This identification of a tier-2 risk triggered a specific mitigation plan. AutoCorp and ChipOne jointly decided to qualify an alternative sub-component supplier in a different geographic region. While this added a small upfront cost, the risk scorecard model clearly showed that it significantly reduced the overall risk profile of the supply chain.

Six months later, a major earthquake struck the region of the primary sub-component factory, shutting it down for an estimated three months. AutoCorp’s competitors, who lacked this level of supply chain visibility, were immediately faced with production line stoppages. Their procurement teams scrambled to find alternative sources in a market where capacity had suddenly evaporated, leading to massive price spikes and extended lead times.

AutoCorp, in contrast, was able to execute its pre-planned response. The commodity manager immediately contacted ChipOne, who activated the already-qualified secondary sub-component supplier. While there was a minor logistical challenge in ramping up the new source, AutoCorp’s production was only minimally affected. The data-driven SRM system had allowed them to transform a potentially catastrophic disruption into a manageable operational issue.

The initial investment in mapping the tier-2 supply base and qualifying a second source paid for itself many times over in avoided lost sales and reputational damage. This case demonstrates that the efficiency gained from SRM is not just about peacetime cost savings; it is about building a resilient system that can withstand real-world shocks.

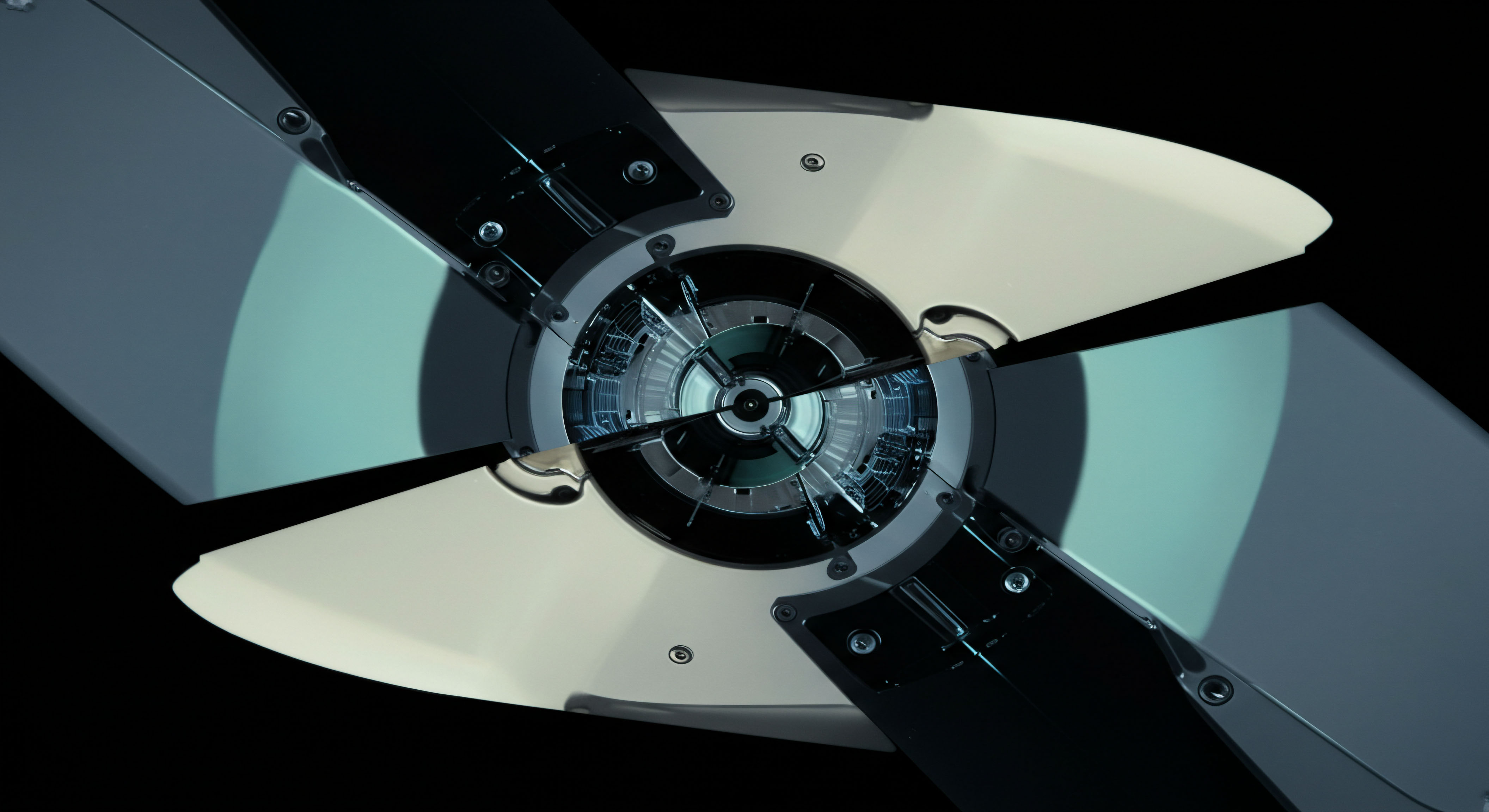

System Integration and Technological Architecture

A modern SRM program cannot operate at scale without a robust and integrated technological backbone. The goal of the technology is to automate data collection, facilitate communication, and provide the analytical tools needed to generate insights from the vast amounts of data generated in the procurement process. The architecture must be designed to create a single source of truth for all supplier-related information.

The core components of a typical SRM technology stack include:

- Enterprise Resource Planning (ERP) System ▴ This is the foundational system that houses all transactional data, including purchase orders, invoices, and receipts. It is the primary source of raw data on spend and delivery performance.

- Supplier Relationship Management (SRM) Suite ▴ This is a dedicated software application that sits on top of the ERP. It provides modules for supplier information management (storing contact details, contracts, and compliance documents), performance management (housing scorecards and tracking KPIs), and risk management (ingesting risk feeds and managing mitigation plans).

- Supplier Portal ▴ This is a web-based interface that provides a secure communication channel between the buying organization and its suppliers. Suppliers can use the portal to receive purchase orders, submit invoices, acknowledge delivery schedules, and view their performance scorecards. This dramatically reduces the administrative burden on both sides.

- Data Analytics Platform ▴ This is the intelligence layer of the stack. It pulls data from the ERP, the SRM suite, and external sources (e.g. financial risk data, commodity market data) into a central data warehouse. Here, powerful analytics tools can be used to build TCO models, generate risk scores, and identify trends and opportunities that would be invisible in the raw data.

The key to making this architecture work is integration. This is typically achieved through Application Programming Interfaces (APIs). For example, an API can be used to automatically pull on-time delivery data from the ERP into the SRM suite’s performance scorecard each month. Another API can connect the SRM suite to a third-party risk provider, automatically updating a supplier’s financial risk score in real-time.

This level of integration eliminates manual data entry, reduces errors, and ensures that decision-makers are always working with the most current and complete information available. It is the technological manifestation of the SRM system itself.

References

- Lambert, D. M. & Schwieterman, M. A. (2012). Supplier relationship management as a macro business process. Supply Chain Management ▴ An International Journal, 17(3), 337-352.

- Kraljic, P. (1983). Purchasing must become supply management. Harvard Business Review, 61(5), 109-117.

- Bensaou, M. (1999). Portfolios of buyer-supplier relationships. Sloan Management Review, 40(4), 35-44.

- Chen, I. J. & Paulraj, A. (2004). Towards a theory of supply chain management ▴ the constructs and measurements. Journal of Operations Management, 22(2), 119-150.

- Handfield, R. B. Krause, D. R. Scannell, T. V. & Monczka, R. M. (2000). Avoid the pitfalls in supplier development. Sloan Management Review, 41(2), 37.

- Zsidisin, G. A. & Ellram, L. M. (2003). An agency theory investigation of supply risk management. Journal of Supply Chain Management, 39(3), 15-27.

- Cousins, P. D. Lawson, B. & Squire, B. (2006). An empirical taxonomy of purchasing strategies. International Journal of Operations & Production Management, 26(7), 775-794.

- Hald, K. S. & Ellegaard, C. (2011). Supplier evaluation processes ▴ the role of interaction in different sourcing situations. International Journal of Physical Distribution & Logistics Management, 41(4), 339-356.

Reflection

Beyond Efficiency a System of Resilience

The initial inquiry into procurement efficiency often begins with a focus on cost and speed. The journey through a systemic understanding of supplier relationship management reveals a more profound truth. The operational efficiencies gained ▴ reduced cycle times, lower administrative overhead, and optimized purchase prices ▴ are the immediate and tangible returns of a well-executed system.

They are, however, merely the first layer of value. The ultimate output of a mature SRM system is not just an efficient procurement function, but a resilient and adaptive enterprise.

The architecture described, from segmentation and governance to quantitative modeling and technological integration, is fundamentally a system for managing uncertainty. It creates a sensory network that extends deep into the supply base, providing early warnings of potential disruptions and the coordinated response mechanisms to navigate them. In a global economic environment characterized by increasing volatility, this capability for resilience may ultimately be the most significant contribution of SRM. The question for any leader is therefore not simply “How can we make our procurement process more efficient?” A more insightful inquiry is, “Have we built a procurement system that is robust enough to protect the entire enterprise from the next inevitable shock?” The answer to that question will define the competitive landscape for years to come.

Glossary

Supplier Relationship Management

Relationship Management

Information Asymmetry

Procurement Process

Total Cost of Ownership

Purchase Price

Value Co-Creation

Kraljic Matrix

Profit Impact

Supply Chain

Performance Management

Balanced Scorecard

Supplier Segmentation

Supplier Risk Scorecard

Total Cost

Risk Scorecard