Concept

The implementation of a niche Request for Proposal (RFP) system represents a fundamental redesign of the communication architecture between a buyer and its supply base. It moves the procurement function beyond a simple document-exchange mechanism into a sophisticated framework for strategic dialogue. A generic RFP process, by its very nature, constrains the conversation to a narrow set of predefined, often price-centric, variables.

This structure can inadvertently create an adversarial dynamic where suppliers provide the minimum information required to be compliant, and buyers are left to extrapolate value from incomplete data sets. The system itself, in its lack of specificity, defaults to treating potential partners as interchangeable commodities, making the cultivation of deep, long-term relationships a counter-current effort.

A niche RFP system, conversely, is engineered with the specific data structures and workflows required for a particular industry or procurement category. Whether for complex manufacturing, specialized professional services, or technology infrastructure, the system is built to ask more intelligent questions. Its design inherently acknowledges that value is multidimensional. The architecture of the RFP process is reconfigured to capture nuanced data points related to innovation capacity, risk mitigation frameworks, total cost of ownership (TCO), and cultural alignment.

This shift in the data-gathering apparatus fundamentally alters the nature of the initial engagement. It signals to the supply market that the buying organization possesses a sophisticated understanding of its own needs and is seeking a partner capable of a commensurate level of strategic engagement.

A niche RFP system transforms the procurement process from a transactional filter into a strategic platform for identifying and cultivating high-potential supplier partnerships.

This technological evolution directly influences the foundation of supplier relationship management (SRM). Effective SRM is predicated on mutual trust, transparency, and shared objectives. A niche RFP system can act as an incubator for these qualities from the very first point of contact. By demanding detailed, verifiable data on subjects like quality control processes, sustainability metrics, or joint business planning capabilities, the system establishes a precedent for a data-rich, transparent relationship.

Suppliers who are unwilling or unable to provide this level of detail are naturally filtered out, not based on price alone, but on their lack of alignment with the buyer’s strategic imperatives. The process becomes a mechanism for qualification based on the potential for a long-term, value-additive partnership, rather than a competition to win a single, isolated contract. The system, therefore, becomes the initial substrate upon which future collaboration and trust are built.

Strategy

Integrating a niche RFP system is a strategic decision to re-architect the very engine of supplier engagement. It provides the necessary framework to move from a reactive, cost-focused procurement model to a proactive, value-driven strategic sourcing discipline. This transition allows an organization to systematically identify and build relationships with suppliers who can provide a sustained competitive advantage.

The strategy hinges on using the technology to create a high-fidelity information environment where the true potential of a partnership can be accurately assessed long before a contract is signed. This approach fundamentally changes how suppliers are evaluated, managed, and integrated into the buyer’s value chain.

The New Taxonomy of Supplier Segmentation

Traditional supplier segmentation models, such as the Kraljic Matrix, are powerful but often rely on lagging indicators like historical spend and a qualitative assessment of supply risk. A niche RFP system provides a rich, forward-looking dataset that enables a more dynamic and predictive approach to segmentation. The information captured during the RFP process ▴ data on a supplier’s R&D investments, their talent management processes, their capacity for demand volatility, and their cybersecurity protocols ▴ allows for a far more granular classification. Suppliers can be segmented not just by what they sell, but by how they create value and manage risk.

This data-driven segmentation allows for the creation of bespoke relationship management strategies. A supplier identified as a “Co-Innovator” through the RFP process will be managed with a different set of protocols and key performance indicators (KPIs) than one classified as a “Utility Provider.” The system provides the initial data to make this distinction, and the subsequent SRM program can be tailored to nurture the specific type of value each segment offers. This prevents the common mistake of applying a one-size-fits-all management approach to a diverse supply base.

| Criteria Category | Generic RFP Evaluation | Niche RFP System Evaluation |

|---|---|---|

| Cost | Unit Price, Payment Terms | Total Cost of Ownership (TCO) Models, Lifecycle Costing, Shared Cost-Reduction Proposals |

| Quality | Compliance with Basic Specifications, ISO Certification | Statistical Process Control (SPC) Data, Root Cause Analysis Procedures, Continuous Improvement Program Details |

| Risk | Financial Stability Report, Insurance Certificates | Business Continuity Plans, Supply Chain Mapping (Tier 2/3), Cybersecurity Audit Results, Geopolitical Risk Exposure Analysis |

| Innovation | Mention of R&D Department | Proposed Joint Innovation Projects, Intellectual Property Sharing Models, Access to Supplier’s Technology Roadmap |

| Partnership | References | Joint Business Planning Frameworks, Proposed Governance Models, Executive-Level Commitment Statements |

Engineering Trust through Procedural Transparency

Trust is the central currency of long-term partnerships. While interpersonal relationships are important, sustainable, business-to-business trust is built upon fair, transparent, and predictable processes. A niche RFP system can be the primary vehicle for engineering this procedural trust.

When suppliers see a clear, logical, and consistently applied evaluation process, their confidence in the buyer’s fairness grows. The system can provide automated feedback, maintain a secure and auditable communication log, and ensure that all contenders are evaluated against the same sophisticated criteria.

This procedural fairness is particularly vital when moving beyond simple price-based decisions. When a contract is awarded to a supplier who is not the lowest bidder, the decision can appear arbitrary or biased in a generic RFP process. In a niche system, the justification is embedded within the data.

The system can clearly demonstrate that the winning supplier scored higher on critical, pre-defined criteria such as innovation potential or risk mitigation, providing a defensible and transparent rationale for the decision. This builds a reputation for the buyer as a sophisticated organization that values true partnership, encouraging high-quality suppliers to invest time and resources in competing for its business.

From Procurement to Joint Value Creation

The ultimate strategic goal of implementing a niche RFP system is to shift the organizational mindset from procurement as a purchasing function to sourcing as a value-creation activity. The system is the enabler of this shift. It provides the platform to have conversations about mutual growth, shared risk, and joint innovation before any commercial commitments are made. The RFP itself becomes a foundational document for the long-term partnership, outlining not just the deliverables and costs, but the shared objectives and governance structure of the relationship.

This approach transforms supplier relationship management from a post-contract, often reactive, activity into a continuous, strategic dialogue that begins with the first RFP. The data captured in the system serves as the baseline for future performance management and collaborative planning. This creates a powerful feedback loop:

- RFP as a Strategic Blueprint ▴ The detailed proposals and commitments made during the RFP process become the charter for the partnership.

- Data-Driven Performance Management ▴ The metrics defined in the RFP (e.g. TCO, innovation contribution) become the KPIs tracked in the SRM program.

- Continuous Improvement Cycle ▴ Performance data from the SRM program informs the requirements and evaluation criteria for future RFPs, creating a cycle of escalating performance and deepening partnerships across the entire supply base.

This strategic alignment ensures that the effort invested in the sourcing process yields returns that extend far beyond the initial cost savings, creating a resilient and innovative supply chain that constitutes a genuine corporate asset.

Execution

The execution phase of integrating a niche RFP system is where strategic intent is translated into operational reality. It requires a disciplined, multi-faceted approach that encompasses technology implementation, process re-engineering, and quantitative performance management. This is about building the high-performance engine for supplier engagement and then operating it with precision to forge durable, high-value partnerships. Success depends on treating the system not as a piece of software to be installed, but as a new operational protocol for the entire organization.

The Quantitative Foundation of Supplier Relations

The core of a successful execution lies in establishing a robust, quantitative framework for evaluating and managing suppliers. This framework begins with the RFP and extends throughout the lifecycle of the relationship. A niche RFP system is designed to capture the specific data points needed to populate a sophisticated supplier scorecard from day one. This scorecard becomes the central, objective tool for all discussions, performance reviews, and strategic planning sessions with the supplier.

The initial RFP responses provide the baseline data for the scorecard. Instead of a simple pass/fail on requirements, the system allows for weighted scoring across dozens of detailed criteria. For example, a supplier’s proposal for a joint technology roadmap might be weighted more heavily than a 2% price difference for a critical component, a calculation that a generic system cannot easily accommodate or justify. This initial, data-rich profile provides a holistic view of the supplier’s capabilities and potential alignment.

A meticulously designed supplier scorecard, populated by data from a niche RFP system, replaces subjective assessments with an objective, shared understanding of value and performance.

Post-contract, this scorecard is continuously updated with real-world performance data, which should be integrated from other enterprise systems (like ERP or Quality Management Systems). This creates a living document that tracks the supplier’s performance against the promises made in their RFP response. It provides a quantitative basis for collaborative problem-solving and for identifying areas for joint improvement. This data-driven approach removes emotion and ambiguity from performance reviews, focusing the conversation on objective facts and shared goals.

| Supplier | Category | Initial RFP Score (Weighted) | Quarterly Performance Metrics | Partnership Health Score (YTD) |

|---|---|---|---|---|

| Innovatech Dynamics | Custom ASIC Design | 92.5 (High weight on Innovation & Risk) | On-Time Delivery ▴ 99.8% First Pass Yield ▴ 97.2% Cost Savings Initiative ▴ +$250k Joint Project Milestones ▴ 5/5 | 94.8 (Exceeding Expectations) |

| Global Components Inc. | Standard Capacitors | 85.0 (High weight on Cost & Reliability) | On-Time Delivery ▴ 98.5% PPM Defect Rate ▴ 150 Cost Savings Initiative ▴ +$50k Joint Project Milestones ▴ N/A | 86.2 (Meeting Expectations) |

| Legacy Systems Co. | Custom ASIC Design | 81.0 (Low score on Innovation & Risk) | On-Time Delivery ▴ 95.1% First Pass Yield ▴ 92.0% Cost Savings Initiative ▴ -$15k (cost overruns) Joint Project Milestones ▴ 2/5 | 75.4 (Performance Improvement Plan Required) |

The Implementation and Integration Protocol

Deploying a niche RFP system effectively requires a clear, phased protocol. It is a significant change management initiative that impacts procurement, engineering, finance, and legal departments. Rushing the implementation without building cross-functional alignment is a primary cause of failure.

- Phase 1 ▴ Deep Discovery and Workflow Architecture. This initial phase involves mapping the specific procurement processes for the target niche. A cross-functional team must define the unique data points, evaluation criteria, and decision workflows that create value in that category. This is where the “niche” aspect is encoded into the system’s DNA. This phase is about defining the questions before seeking answers.

- Phase 2 ▴ System Configuration and Data Model Setup. Working with the technology provider, the defined workflows and data requirements are configured in the system. This includes building the templates for RFPs, the structure of the evaluation scorecards, and the rules for automated communication. This is a technical build-out based on the strategic architecture from Phase 1.

- Phase 3 ▴ Pilot Program with Strategic Suppliers. Before a full rollout, the system should be tested with a small group of trusted, incumbent suppliers. This pilot program helps identify any friction in the process, refine the user interface, and demonstrate the value of the new approach to internal stakeholders and key suppliers. It also serves as a training ground.

- Phase 4 ▴ Phased Rollout and Training. The system is rolled out to the rest of the organization, category by category. Comprehensive training is essential for all users, focusing not just on how to use the software, but on why the new process is being implemented and how it supports the company’s strategic goals.

- Phase 5 ▴ Integration with Enterprise Systems. To achieve maximum value, the niche RFP system must be integrated with other core platforms. This includes connecting to the ERP for financial data, the PLM (Product Lifecycle Management) system for technical specifications, and dedicated SRM or supplier performance modules. This creates a single source of truth for all supplier-related data, from initial bid to final payment and performance review.

Predictive Scenario Analysis a Case Study

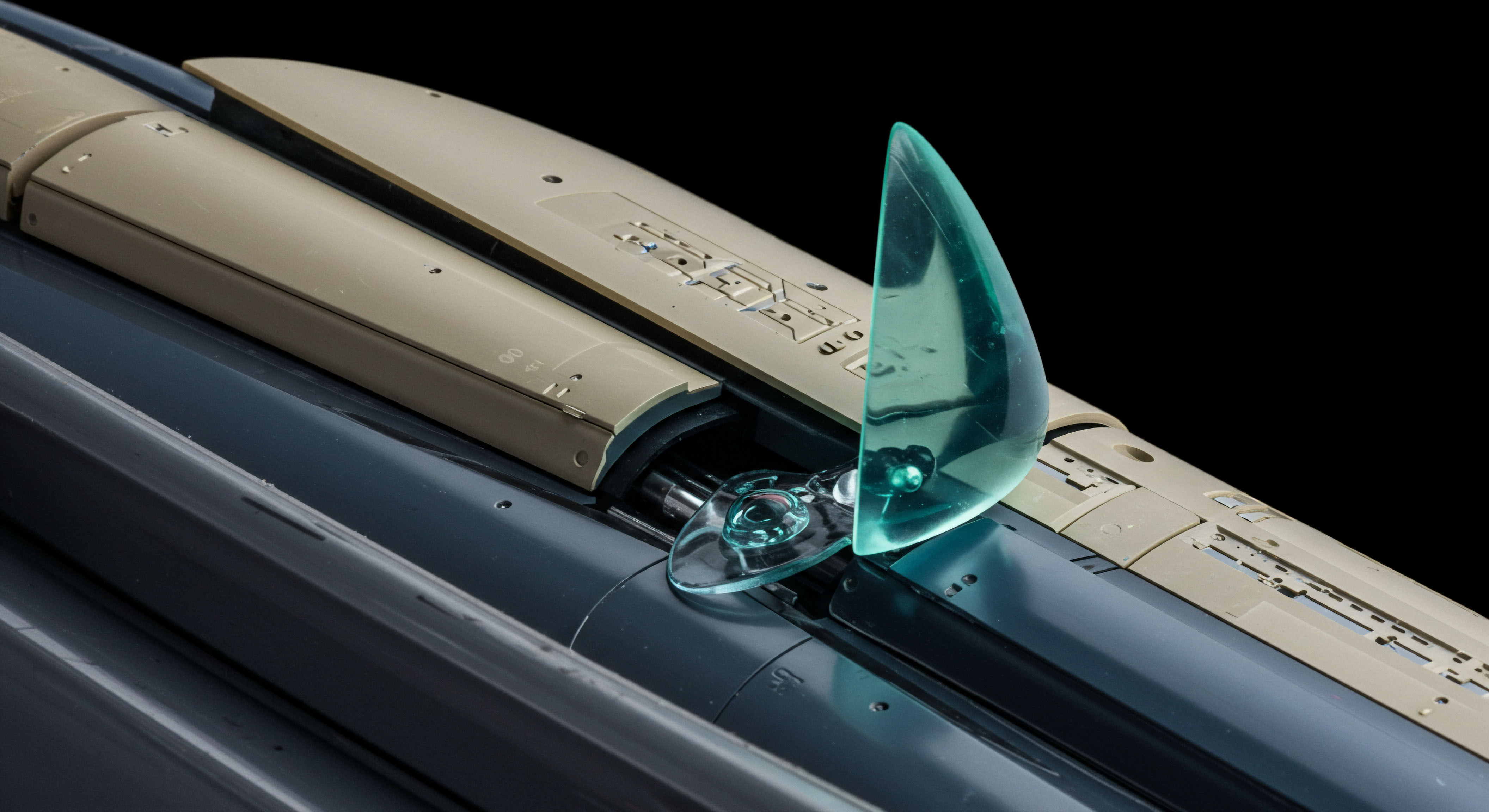

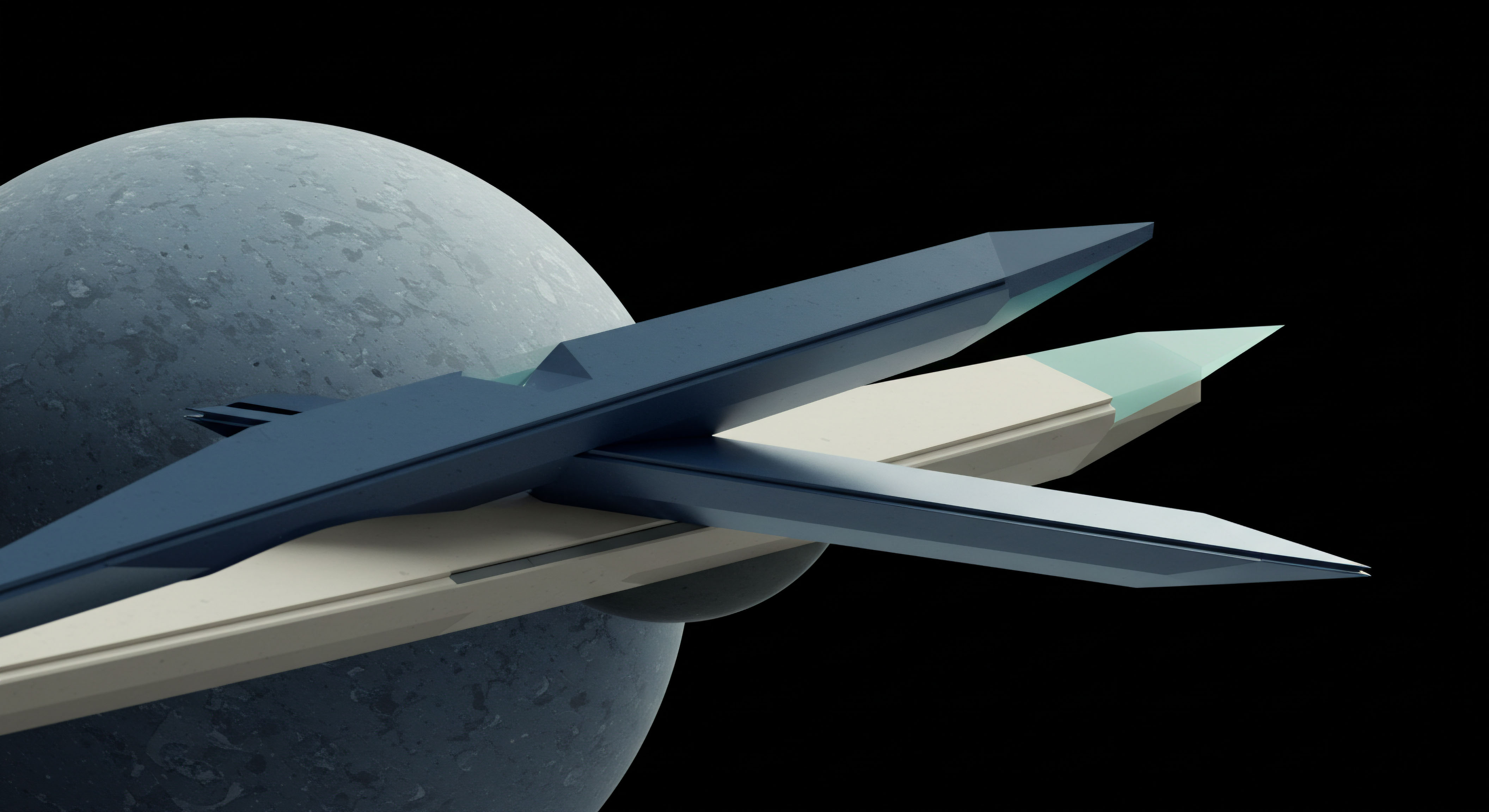

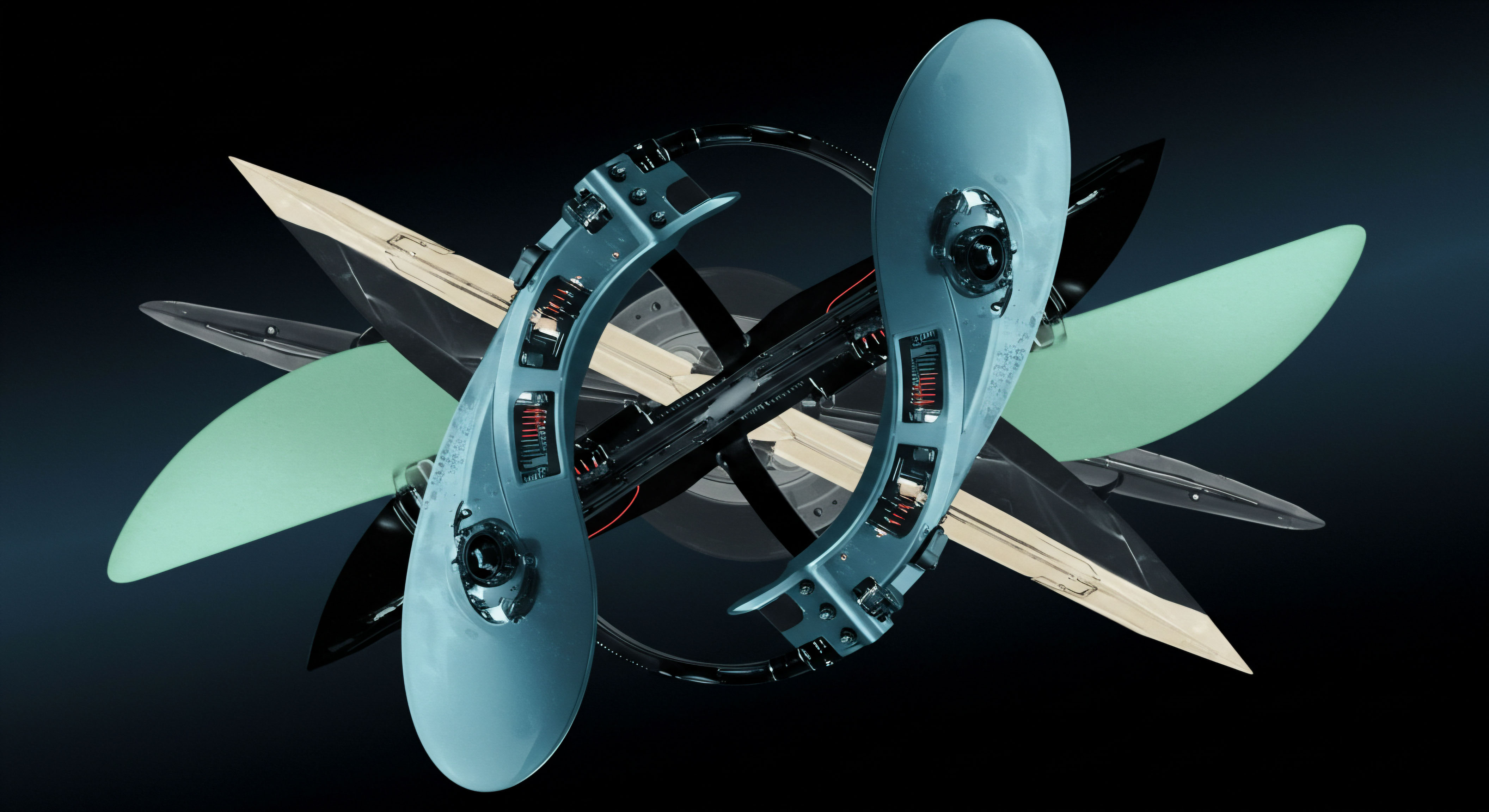

Consider “Maritime Propulsion Systems (MPS),” a manufacturer of complex, high-performance marine engines. MPS traditionally procured critical control system software through a generic RFP process focused heavily on upfront licensing costs and basic feature checklists. This led to relationships with suppliers who were technically compliant but offered little in terms of co-development or long-term support, resulting in costly integration challenges and technological stagnation.

MPS decided to implement a niche RFP system specifically designed for complex software and technology partnerships. The new RFP process was architected to evaluate suppliers on a completely different set of criteria. It required bidders to submit detailed proposals on their development methodology (Agile vs.

Waterfall), their talent retention statistics for key engineers, a proposed five-year joint technology roadmap, and a flexible IP model that allowed for co-owned innovations. The evaluation scorecard weighted “Collaborative Potential” and “Lifecycle Support Model” at 40%, while “Upfront Cost” was weighted at only 15%.

A smaller, more innovative firm, “Nautical Software Solutions (NSS),” which had previously been uncompetitive in MPS’s old cost-focused RFPs, scored exceptionally high. Their proposal included a detailed plan for embedding two of their senior engineers with the MPS team during development and a transparent, milestone-based payment structure tied to performance outcomes. While their initial bid was 12% higher than the incumbent, the niche RFP system’s TCO model predicted a 30% lower total cost over the five-year lifecycle due to reduced integration work, faster time-to-market, and planned performance improvements.

MPS awarded the contract to NSS. The data and commitments captured in the RFP system became the foundation of their partnership agreement. They used the proposed joint technology roadmap as the basis for their quarterly strategic business reviews. The milestone-based payment structure, managed through the system, created a perfect alignment of incentives.

Two years into the partnership, a joint innovation developed through this collaborative framework resulted in a 7% improvement in fuel efficiency for MPS’s flagship engine, a competitive advantage worth tens of millions of dollars. The niche RFP system did not just help MPS buy software; it provided the operational and quantitative framework to forge a strategic partnership that created immense, long-term value. This outcome was structurally impossible under their previous procurement protocol.

References

- Ahmad, Muhammad W. et al. “The Impact of E-Procurement on Supply Chain Performance in the Manufacturing Industry of Pakistan.” International Journal of Supply Chain Management, vol. 7, no. 5, 2018, pp. 329-336.

- Cankaya, S. K. “Strategic Sourcing ▴ A Competitive Weapon in the Market.” Journal of Global Operations and Strategic Sourcing, vol. 13, no. 2, 2020, pp. 125-144.

- Johnsen, Thomas E. et al. Purchasing and Supply Chain Management ▴ A Sustainability Perspective. Routledge, 2014.

- KPMG. “The Future of Procurement ▴ A Strategic Value Proposition.” KPMG International, 2024.

- Layaq, Asad, et al. “Strategic Sourcing and its Impact on Firm Performance ▴ The Mediating Role of Supplier Relationship Management.” Journal of Purchasing & Supply Management, vol. 25, no. 4, 2019, article 100557.

- Schoenherr, Tobias. “The Role of Electronic Sourcing Technologies in the Development of Strategic Sourcing.” Journal of Business Logistics, vol. 40, no. 1, 2019, pp. 47-65.

- Singh, S. and Chan, C. “The Influence of Green Procurement on E-Procurement Technology Adoption and Firm Performance.” Journal of Cleaner Production, vol. 347, 2022, article 131278.

- Talluri, Srinivas, and Ram Narasimhan. “A Methodology for Strategic Sourcing.” European Journal of Operational Research, vol. 154, no. 1, 2004, pp. 236-250.

- Usai, A. et al. “Digital Technology Adoption and its Impact on Innovation ▴ A Study of Italian Firms.” Technological Forecasting and Social Change, vol. 166, 2021, article 120612.

From Process to Protocol

The transition to a niche RFP system is ultimately a declaration of strategic intent. It signals a move away from viewing procurement as a series of discrete, tactical events toward understanding strategic sourcing as a continuous, integrated system for value creation. The technology itself is a potent catalyst, but the enduring influence on supplier relationships comes from the operational discipline and analytical rigor it enables.

The system provides a new language for collaboration, one based on shared data and mutually understood objectives. It builds an architecture where trust is a function of transparent processes and predictable outcomes.

Reflecting on this framework prompts a critical examination of an organization’s existing communication architecture. What conversations are being prevented by the limitations of current processes? What dimensions of value are being ignored because the system lacks the capacity to measure them?

The implementation of a specialized system is an opportunity to redefine the very nature of partnership, transforming the supply base from a source of cost-containment into a network of strategic assets capable of driving long-term, sustainable growth. The ultimate advantage is found in the quality of the dialogue the system makes possible.

Glossary

Rfp Process

Niche Rfp System

Total Cost

Supplier Relationship Management

Rfp System

Strategic Sourcing

Relationship Management

Procedural Trust

Supplier Relationship

Supply Chain

Cost Savings