Concept

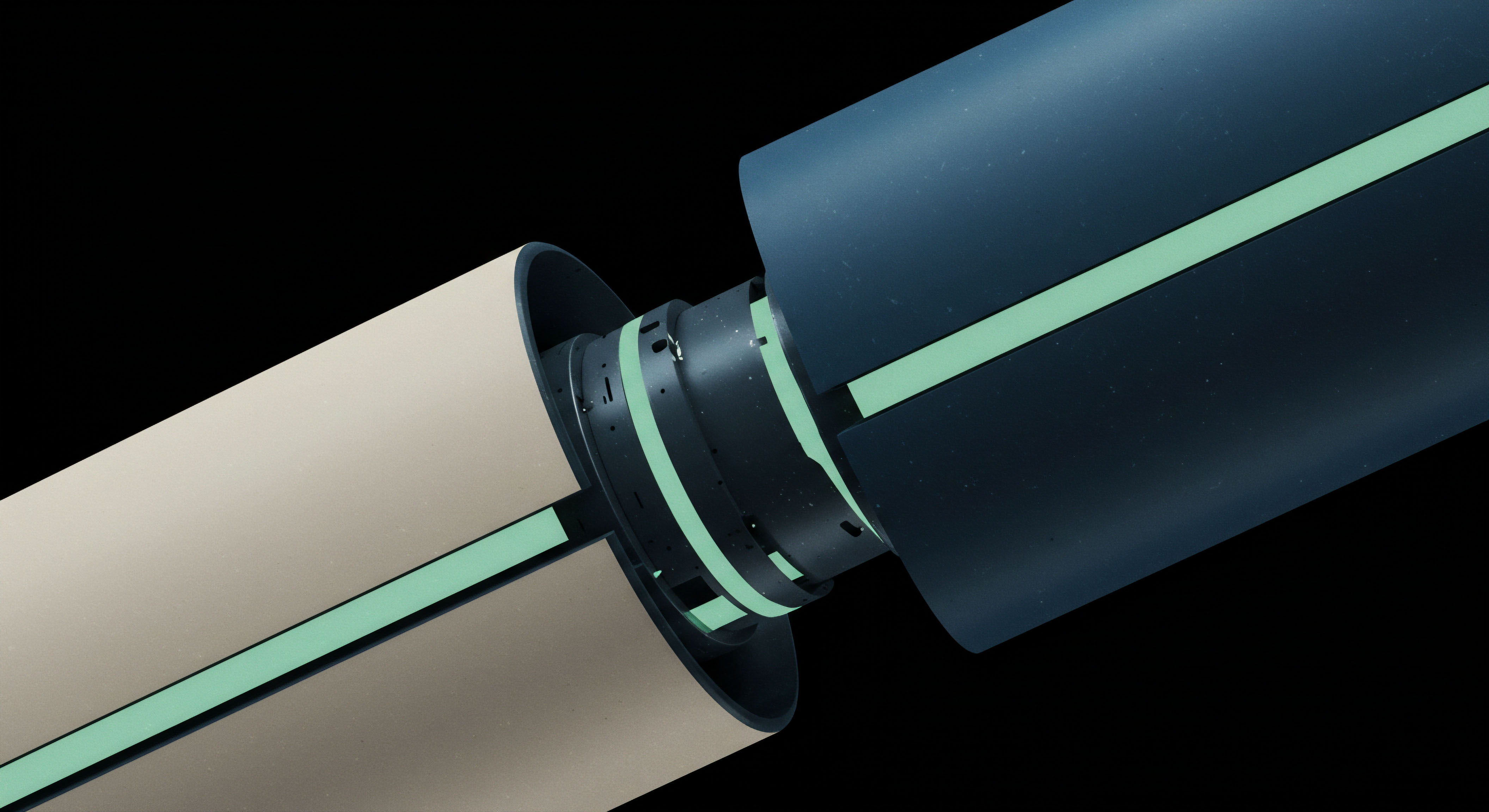

The differentiation of Key Performance Indicators (KPIs) for Request for Proposal (RFP) optimization between direct and indirect procurement categories is a function of their intrinsic relationship to an organization’s value creation process. Viewing procurement through a systems lens clarifies this distinction. Direct procurement acts as an integral component of the core operational system ▴ the very mechanism that produces the final product or service.

Indirect procurement, conversely, constitutes the essential support infrastructure that enables the core system to function with efficiency and stability. The KPIs for each, therefore, measure fundamentally different outcomes.

Direct procurement involves the acquisition of goods and services that are inextricably linked to the end product. This includes raw materials, components, and subsystems that form the bill of materials. The performance of these inputs directly dictates the quality, cost, and availability of the final offering.

Consequently, RFP optimization in this domain is not merely a cost-reduction exercise; it is a critical process of managing supply chain integrity, product quality, and operational continuity. The KPIs must reflect this systemic importance, focusing on metrics that quantify resilience, quality assurance, and supplier-led innovation.

In contrast, indirect procurement encompasses all goods and services necessary for day-to-day operations that do not become part of the final product. This broad category includes items like IT hardware and software, marketing services, professional fees, and office supplies. While essential, their impact on the end product is secondary. The primary objective of RFP optimization for indirect categories is to enhance operational efficiency, enforce compliance, and achieve cost control across the enterprise.

The associated KPIs, therefore, are designed to measure process efficiency, spend under management, and the total cost of ownership (TCO), rather than the granular performance of the goods or services themselves. The systemic function dictates the measurement framework.

Strategy

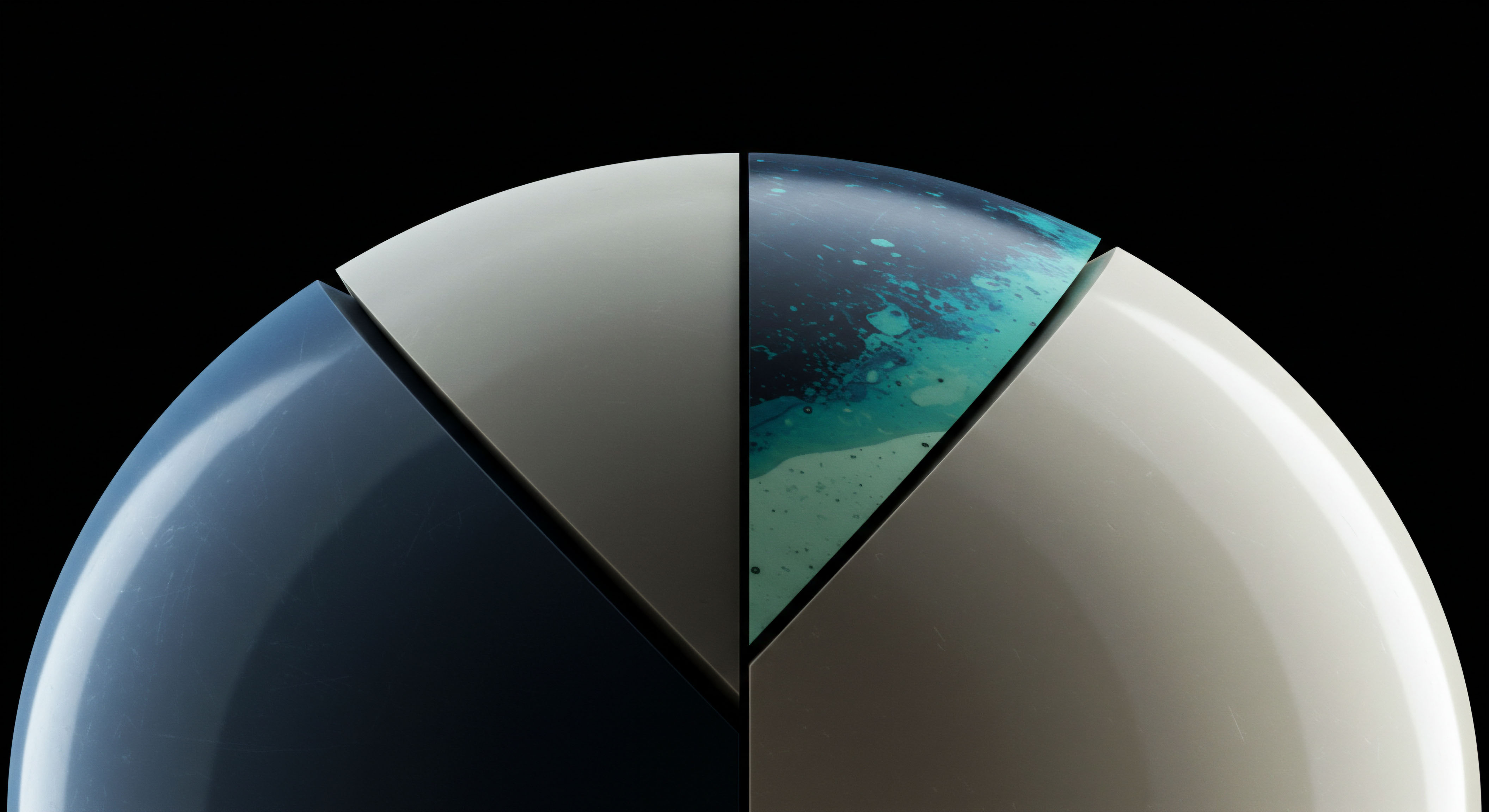

The Strategic Imperative in Direct Sourcing

The strategic framework for direct procurement RFPs is built upon the pillars of risk mitigation, long-term value creation, and supply chain resilience. Given that direct materials are the lifeblood of production, a disruption in supply or a compromise in quality can have immediate and severe consequences on revenue and brand reputation. The strategy transcends transactional purchasing, aiming to forge deep, collaborative partnerships with suppliers who can contribute to innovation and provide a stable, high-quality supply base. The RFP process becomes a mechanism for identifying partners, not just vendors.

Key strategic objectives that shape direct procurement KPIs include:

- Supply Chain Fortification ▴ The goal is to build a resilient and agile supply network that can withstand geopolitical, environmental, and economic shocks. This involves qualifying suppliers across different geographic regions and ensuring they have robust business continuity plans.

- Quality Assurance Integration ▴ The strategy focuses on moving quality control upstream. Suppliers are evaluated on their internal quality management systems, defect rates, and ability to adhere to stringent product specifications. The KPI framework must measure quality as a proactive process, not a reactive inspection.

- Collaborative Innovation ▴ Leading organizations leverage direct suppliers as an extension of their research and development teams. The RFP strategy seeks to identify suppliers with strong engineering capabilities who can contribute to product design, cost-down initiatives, and the introduction of new technologies.

- Total Cost of Ownership Optimization ▴ The focus extends beyond the unit price to encompass the full lifetime cost of a component. This includes logistics, inventory holding costs, warranty claims, and the cost of poor quality. The strategy aims to minimize this total cost, recognizing that the lowest bid price may lead to higher downstream expenses.

The strategic aim of a direct procurement RFP is to build a resilient, high-quality supply network that functions as a seamless extension of the core production system.

The Strategic Framework for Indirect Sourcing

For indirect procurement, the strategy revolves around maximizing operational efficiency, achieving economies of scale, and ensuring compliance with internal purchasing policies. The diversity and fragmentation of indirect spend across an organization present a significant opportunity for value capture through standardization and consolidation. The RFP is a powerful tool for leveraging the organization’s total purchasing power and streamlining complex, often decentralized, buying processes.

The strategic focus for indirect procurement KPIs is guided by these principles:

- Spend Consolidation and Category Management ▴ The primary strategy is to aggregate spend across business units to negotiate superior pricing and service levels. This involves a detailed analysis of spending patterns to identify opportunities for supplier consolidation and the creation of standardized catalogs.

- Process Automation and Efficiency ▴ Indirect procurement is often characterized by a high volume of low-value transactions. A key strategic goal is to automate the procure-to-pay cycle, reducing the administrative burden and freeing up resources for more strategic activities. KPIs measure cycle times and transaction costs to drive continuous improvement.

- Demand Management and Policy Compliance ▴ The strategy aims to control “maverick spend” ▴ purchases made outside of approved channels. By implementing user-friendly e-procurement platforms and preferred supplier lists, the organization can guide employees to make compliant, cost-effective purchasing decisions.

- Stakeholder Satisfaction and Service Levels ▴ Unlike direct procurement, the “customer” of indirect procurement is an internal employee. A crucial strategic element is ensuring that the sourced services and goods meet the needs of the business stakeholders in terms of quality, availability, and ease of use.

The following table delineates the core strategic differences that inform KPI selection for RFP optimization in these two domains.

| Strategic Dimension | Direct Procurement Strategic Focus | Indirect Procurement Strategic Focus |

|---|---|---|

| Primary Objective | Ensure production continuity and product quality. | Enhance operational efficiency and reduce enterprise-wide costs. |

| Risk Management | Mitigate supply chain disruptions, quality failures, and single-source dependency. | Control maverick spending, ensure policy compliance, and manage contractual risks. |

| Supplier Relationship | Develop long-term, collaborative partnerships for innovation and stability. | Leverage competition and consolidate spend among preferred, high-performing vendors. |

| Cost Focus | Minimize Total Cost of Ownership (TCO), including quality and logistics costs. | Achieve hard cost savings through negotiation and process efficiency. |

| Innovation Goal | Co-develop new products and technologies with strategic suppliers. | Adopt new technologies and services that improve internal business processes. |

Execution

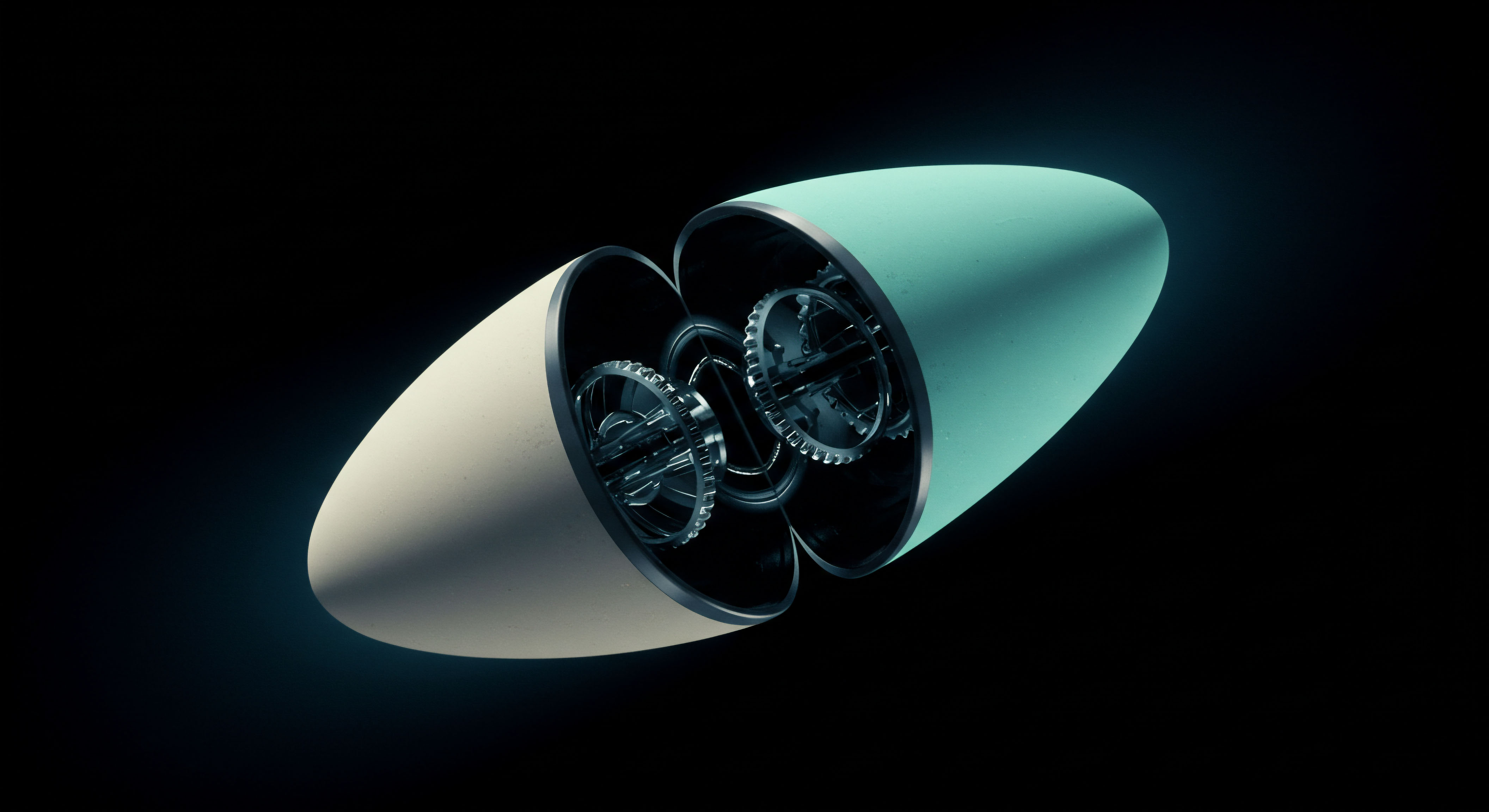

The Operational Playbook for Direct Procurement KPI Optimization

Executing an RFP for a critical direct material requires a KPI framework that is deeply integrated with the manufacturing and quality control systems of the organization. The selection of a supplier is a long-term commitment that has a direct bearing on the company’s financial performance and market standing. The KPI structure must be granular, quantitative, and weighted to reflect the most critical operational priorities.

Consider the scenario of sourcing a custom-designed semiconductor for a new generation of smart devices. The RFP optimization process would be governed by a multi-faceted KPI model that prioritizes supply assurance and technological capability over simple price competition.

- Establish Cross-Functional Team ▴ The KPI development team must include representatives from engineering, quality assurance, supply chain, and finance. This ensures that the metrics cover all aspects of supplier performance, from technical specifications to financial stability.

- Define Non-Negotiable Thresholds ▴ Before issuing the RFP, the team must establish minimum acceptable performance levels for critical KPIs. For instance, a supplier might be disqualified if their demonstrated defect rate exceeds 50 parts per million (PPM) or if they lack a certified IATF 16949 quality management system.

- Develop a Weighted Scorecard ▴ The core of the execution is a detailed scorecard where each KPI is assigned a weight corresponding to its strategic importance. For a critical component, the weighting might be heavily skewed towards quality and supply chain resilience.

- Incorporate Site Audits and Data Verification ▴ The KPI data submitted in an RFP response must be rigorously validated. This involves on-site audits of the supplier’s manufacturing facilities, examination of their quality control records, and independent financial health assessments.

- Model Total Cost of Ownership ▴ The finance representative on the team is responsible for building a comprehensive TCO model. This model translates various performance KPIs, such as yield rate and delivery lead time, into financial terms, allowing for a more holistic comparison of bids.

The following table provides an example of a detailed KPI scorecard for this direct procurement scenario.

| KPI Category | Specific KPI | Metric / Formula | Target | Weighting (%) | Data Source |

|---|---|---|---|---|---|

| Quality & Reliability | Defect Rate (PPM) | (Number of Defective Units / Total Units Shipped) 1,000,000 | < 50 PPM | 35% | Third-Party Test Reports; Historical Data |

| Supply Chain Resilience | Geographic Redundancy | Score (1-5) based on availability of qualified production sites in different regions. | Score > 4 | 25% | Supplier BCP; Site Audit Reports |

| Technical Capability | Process Yield | Percentage of units passing all manufacturing tests on the first pass. | > 99.5% | 20% | Audited Production Data |

| Total Cost of Ownership | Landed Cost per Unit | Unit Price + Logistics + Tariffs + Inventory Holding Cost | < $15.50 | 15% | Supplier Quote; Logistics Model |

| Partnership & Innovation | R&D Resource Commitment | Number of dedicated engineers assigned to the account. | > 3 FTEs | 5% | RFP Response; Supplier Org Chart |

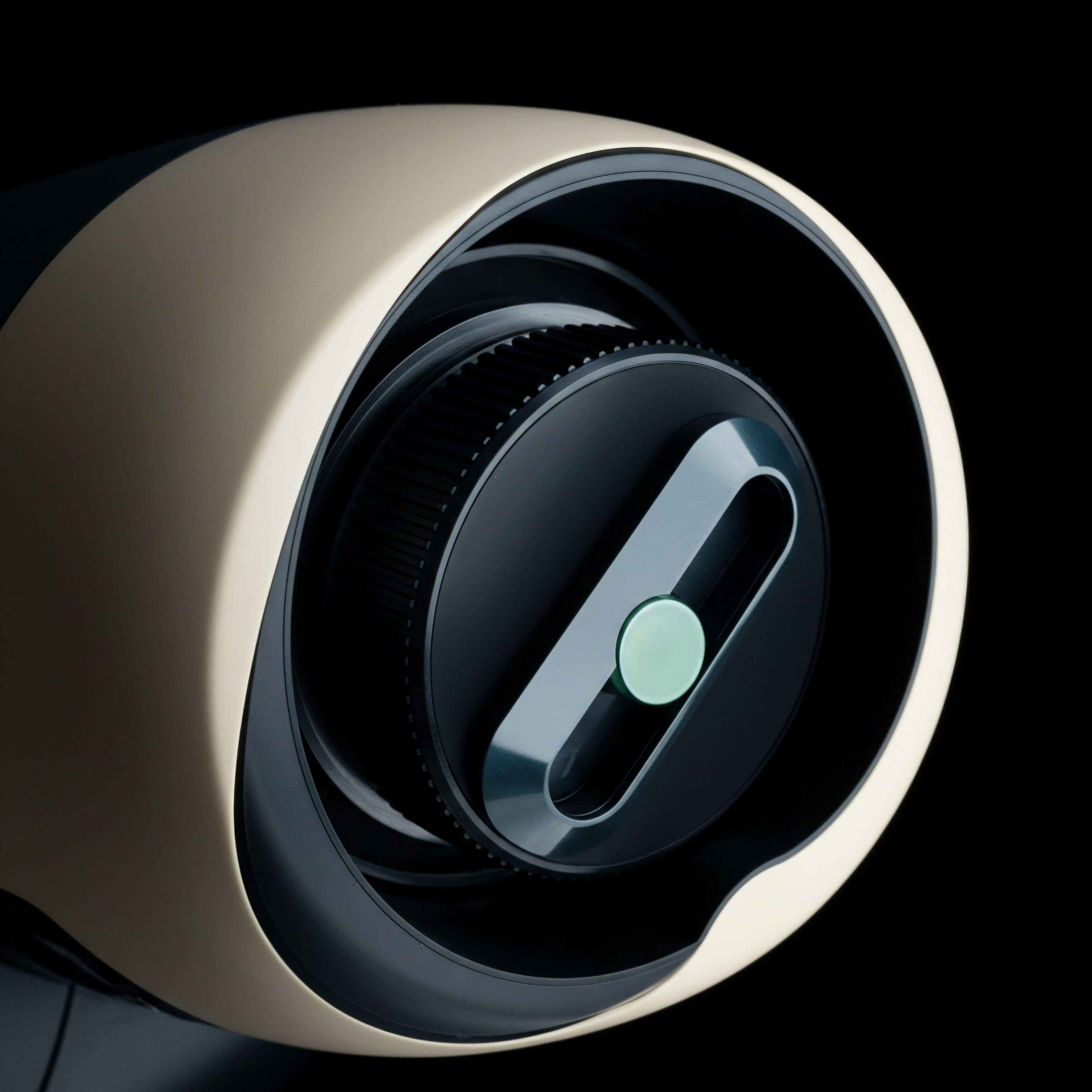

The Operational Playbook for Indirect Procurement KPI Optimization

The execution of an RFP for an indirect category, such as enterprise-wide marketing automation software, requires a different set of KPIs and a distinct operational playbook. The focus shifts from manufacturing and logistics to process efficiency, user adoption, and compliance. The goal is to select a solution that delivers the best value for the entire organization while minimizing the administrative overhead.

For indirect procurement, the KPI framework must quantify the impact on business process efficiency and the total cost to the organization, not just the purchase price.

The execution process for an indirect RFP is centered on stakeholder alignment and measuring the impact on business processes.

- Stakeholder Requirements Gathering ▴ The first step is to conduct workshops with the primary users of the service (e.g. the marketing, sales, and IT departments) to define functional requirements and desired business outcomes. These outcomes form the basis of the service-level KPIs.

- Focus on Total Cost of Ownership ▴ The evaluation must extend far beyond the subscription fee. The TCO model for a SaaS platform includes implementation costs, data migration, user training, integration with existing systems (like CRM), and ongoing support.

- Measure Process Improvement ▴ The most valuable KPIs for indirect procurement quantify efficiency gains. For a marketing automation platform, this could be the reduction in time required to launch a new campaign or the automated qualification of sales leads, freeing up employee time.

- Prioritize Security and Compliance ▴ For any software or service that handles company or customer data, security and data privacy compliance are paramount. KPIs must include adherence to standards like SOC 2, ISO 27001, and GDPR, with validation through independent audit reports.

- Evaluate Supplier Viability and Support ▴ The chosen supplier must be a stable partner with a strong track record and a clear product roadmap. KPIs should assess the provider’s financial health, customer support responsiveness (via Service Level Agreements), and the quality of their training and onboarding programs.

This approach ensures that the chosen solution is not only cost-effective but also drives tangible improvements in how the organization operates.

References

- Monczka, Robert M. et al. Purchasing and Supply Chain Management. Cengage Learning, 2015.

- Handfield, Robert B. et al. “A Causal Model of Supplier-Management System Implementation and Performance.” Journal of Operations Management, vol. 36, 2015, pp. 29-41.

- Gelderman, Cees J. and Arjan J. van Weele. “Handling Measurement Issues and Strategic Directions in Sourcing ▴ A Review and Implications.” Journal of Purchasing and Supply Management, vol. 13, no. 4, 2007, pp. 237-51.

- CIPS. “Total Cost of Ownership (TCO).” Chartered Institute of Procurement & Supply, cips.org/knowledge/procurement-topics-and-skills/strategy-policy/total-cost-of-ownership-tco. Accessed 6 Aug. 2025.

- Baily, Peter, et al. Procurement, Principles & Management. Pearson Education, 2015.

- Krause, Daniel R. et al. “The Antecedents of Abusive Supplier Relationships ▴ A Behavioral Perspective.” Journal of Operations Management, vol. 25, no. 4, 2007, pp. 895-913.

- Carr, Amelia S. and J. N. Pearson. “Strategically Managed Buyer-Supplier Relationships and Performance Outcomes.” Journal of Operations Management, vol. 17, no. 5, 1999, pp. 497-519.

- Liker, Jeffrey K. and Thomas Y. Choi. “Building Deep Supplier Relationships.” Harvard Business Review, vol. 82, no. 12, 2004, pp. 104-13.

Reflection

The KPI Framework as a Systemic Mirror

Ultimately, the architecture of an RFP’s KPI framework does more than guide a sourcing decision; it holds up a mirror to the organization’s operational priorities and strategic intent. The allocation of weightings, the selection of metrics, and the rigor of their validation reveal what the organization truly values. For direct categories, this value is expressed in the language of systemic integrity, product quality, and supply chain resilience. The KPIs are a proxy for the health of the core production engine.

For indirect categories, the value is articulated through the lens of operational leverage, efficiency, and enterprise-wide discipline. These KPIs measure the performance of the systems that support the core engine, ensuring it can operate without unnecessary friction or cost burdens. A failure to differentiate these two KPI philosophies leads to suboptimal outcomes. Applying a cost-centric, indirect framework to a strategic direct material supplier risks compromising the final product.

Conversely, applying a complex, quality-focused direct framework to a simple indirect purchase introduces unnecessary complexity and administrative waste. The act of designing the KPI model is, therefore, an act of profound strategic clarification.

Glossary

Indirect Procurement

Direct Procurement

Rfp Optimization

Supply Chain

Operational Efficiency

Total Cost of Ownership

Process Efficiency

Supply Chain Resilience

Kpi Framework

Total Cost

Category Management

Procure-To-Pay Cycle

Demand Management