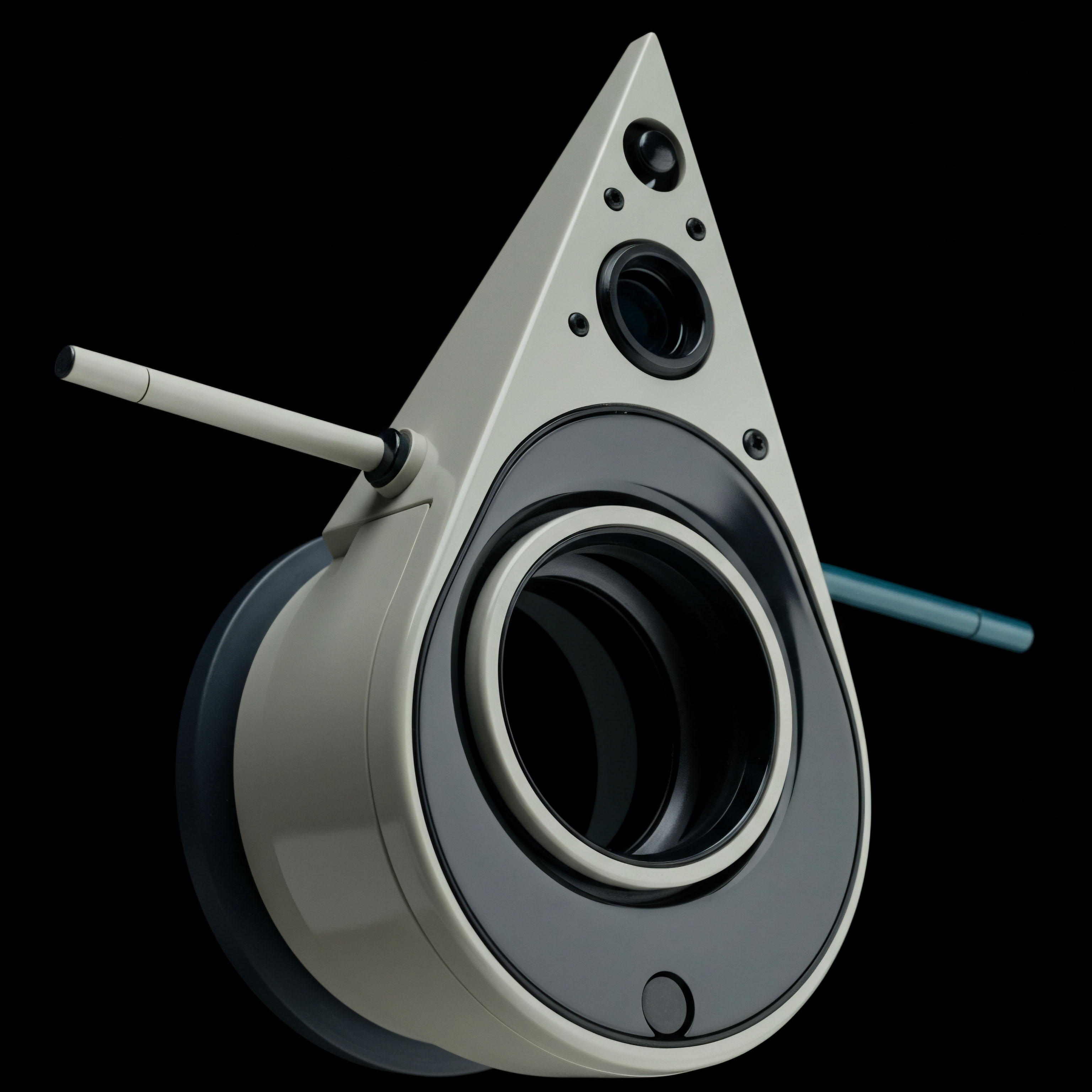

Concept

The operational stability of a global supply chain is contingent upon the velocity and integrity of its information flows. Disruptions, therefore, are seldom failures of logistics alone; they represent a critical breakdown in a system’s capacity to receive, process, and act upon vital data. An unforeseen event, whether a sudden port closure, a geopolitical flare-up, or a sub-tier supplier’s component failure, introduces a cascade of variables that legacy systems, reliant on static, historical data, are structurally incapable of managing.

The consequence is a reactive posture, where decisions are made based on lagging indicators, introducing significant friction, cost, and risk into the system. The core challenge is one of signal integrity and processing speed in a high-stakes, dynamic environment.

Integrating real-time data streams into a Request for Proposal (RFP) system fundamentally alters this operational paradigm. It transforms the RFP process from a periodic, tactical procurement tool into a dynamic, strategic nerve center for the entire supply chain. This system becomes the apparatus through which the organization senses and responds to environmental volatility with precision and speed. It functions as an integrated operating system for supply chain resilience, where live data on supplier capacity, lead times, logistical bottlenecks, and material costs are continuously ingested and analyzed.

This provides decision-makers with a persistent, high-fidelity model of their supply network’s state. The ability to issue, receive, and analyze proposals in near real-time, informed by this live data, allows an organization to execute complex contingency plans, re-source critical components, and re-route logistics with a level of agility that neutralizes the impact of the initial disruption. This is about architecting a supply chain that is inherently adaptive, capable of reconfiguring its pathways and partnerships in response to live stimuli.

The Physics of Supply Chain Information

Every supply chain operates according to principles of information latency. The time between a disruptive event occurring and an organization taking effective action determines the magnitude of the impact. Traditional procurement models, characterized by manual processes, email chains, and quarterly supplier reviews, introduce immense latency.

Information travels slowly, is often fragmented, and requires significant human effort to synthesize into a coherent operational picture. This high-latency environment means that by the time a response is formulated, the ground truth of the situation has already shifted, rendering the action suboptimal or even counterproductive.

A supply chain’s resilience is directly proportional to the speed at which it can convert real-world events into actionable intelligence.

A real-time, data-infused RFP system fundamentally changes this equation by minimizing information latency. It achieves this through several mechanisms. First, it centralizes communication, creating a single source of truth for all sourcing activities. Second, it automates the collection and normalization of data from disparate sources, including supplier inputs, market intelligence feeds, and internal ERP systems.

Third, it provides the analytical tools to model the impact of different sourcing decisions before they are made. This compression of the sense-analyze-act cycle is the foundational advantage. It allows the organization to operate inside the disruption’s own decision loop, mitigating its effects before they can propagate and amplify throughout the network.

From Static Contracts to Dynamic Partnerships

The traditional approach to supplier management is built on a foundation of static, long-term contracts. While these provide a degree of price stability, they also introduce significant rigidity into the supply chain. When a primary supplier is impacted by a disruption, activating a secondary or tertiary supplier is often a slow, manual process fraught with uncertainty about their current capacity, pricing, and ability to meet quality standards. This is a structural vulnerability that is a direct consequence of an information-poor procurement strategy.

A real-time RFP system facilitates a more fluid and resilient approach to supplier network management. It allows for the continuous qualification and vetting of a broader base of potential suppliers. By maintaining a live database of these suppliers’ capabilities, performance metrics, and real-time availability, the system transforms the supplier base from a fixed hierarchy into a dynamic and responsive network.

When a disruption occurs, the system can instantly identify and solicit proposals from a pre-vetted pool of qualified alternatives. This capability to dynamically re-allocate sourcing based on live conditions moves the organization from a model of supplier dependency to one of supplier optionality, which is a cornerstone of modern supply chain resilience.

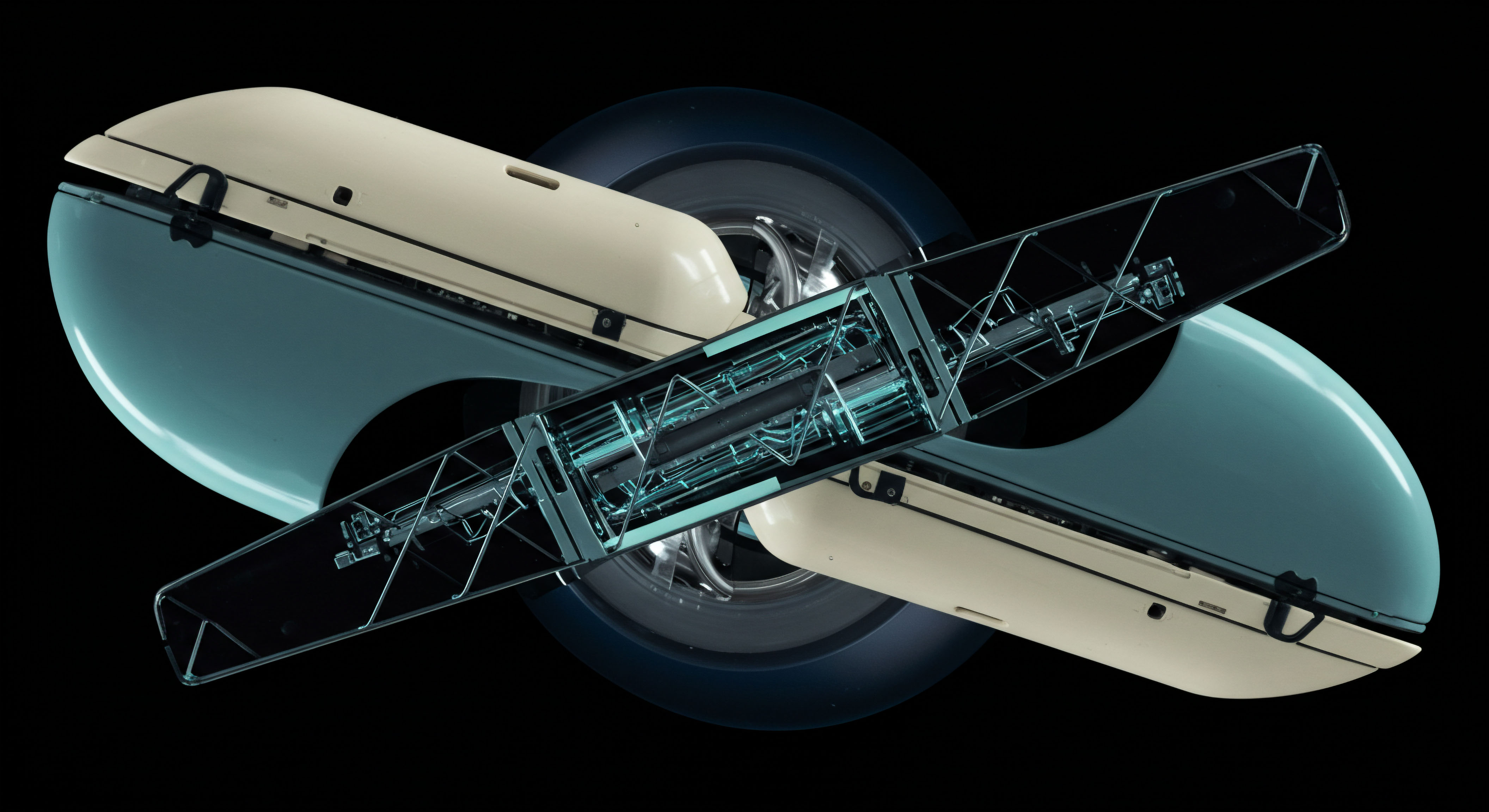

Strategy

The strategic implementation of a real-time RFP system is about architecting a data-centric defense mechanism against supply chain volatility. It requires moving beyond the simple automation of procurement tasks and developing a holistic strategy that integrates data, analytics, and operational workflows into a cohesive, resilient system. The objective is to build an organization that can not only withstand disruptions but can also derive a competitive advantage from its superior ability to navigate them. This strategy rests on three pillars ▴ achieving systemic foresight through data fusion, designing a resilient and adaptive supplier network, and operationalizing a proactive disruption response framework.

Achieving Systemic Foresight through Data Fusion

A real-time RFP system’s strategic value is directly tied to the quality and breadth of the data it can ingest and synthesize. A siloed data stream, such as supplier price quotes, provides only a limited tactical advantage. True strategic foresight emerges from the fusion of multiple, disparate data sources into a single, coherent operational picture. This integrated data model allows for a more sophisticated understanding of the supply chain’s second and third-order vulnerabilities.

The key data streams to integrate include:

- Internal Data ▴ This includes information from the organization’s Enterprise Resource Planning (ERP) system, such as current inventory levels, production schedules, and demand forecasts. Integrating this data allows the RFP system to understand the immediate internal impact of a potential sourcing decision.

- Supplier Data ▴ This goes beyond basic contact information. It includes real-time feeds on supplier production capacity, their own inventory levels, quality control metrics, and financial health indicators. This data provides a clear view of a supplier’s ability to deliver on their proposals.

- Logistics Data ▴ Real-time tracking of shipments, port congestion levels, weather patterns, and transportation costs are critical. This allows for the accurate calculation of lead times and the identification of potential logistical bottlenecks before they become critical.

- Market Intelligence ▴ This includes data on commodity price fluctuations, geopolitical risk assessments, regulatory changes, and even social media sentiment analysis related to specific regions or industries. This provides the contextual layer needed to anticipate disruptions before they occur.

Fusing these data streams within the RFP system allows for the creation of a “digital twin” of the supply chain ▴ a dynamic model that can be used to simulate the impact of various scenarios and test the effectiveness of different response strategies. This is the foundation of a truly proactive and data-driven approach to risk management.

Designing a Resilient and Adaptive Supplier Network

A resilient supply chain is one that has options. Relying on a single supplier for a critical component, no matter how strong the relationship, is a strategic liability. A real-time RFP system is the central tool for building and managing a multi-tiered, geographically dispersed, and highly adaptive supplier network. The strategy involves a continuous process of supplier discovery, qualification, and performance management.

The following table contrasts the traditional approach to supplier management with a modern, data-driven strategy enabled by a real-time RFP system.

| Aspect | Traditional Supplier Management | Real-Time, Data-Driven Supplier Management |

|---|---|---|

| Supplier Discovery | Periodic, often manual, searches conducted in response to a specific need or contract expiration. | Continuous, automated monitoring of the market to identify new potential suppliers based on a wide range of criteria. |

| Supplier Vetting | A lengthy, project-based process involving manual document exchange, on-site audits, and subjective assessments. | An automated, data-driven process that uses real-time information on financial stability, quality certifications, and past performance to pre-qualify suppliers. |

| Performance Tracking | Based on historical data, such as quarterly business reviews and annual performance scorecards. Lagging indicators dominate. | Based on real-time metrics, such as on-time-in-full (OTIF) delivery rates, quality inspection results, and responsiveness to inquiries. Leading indicators are prioritized. |

| Relationship Model | Static and hierarchical, with a clear distinction between primary, secondary, and tertiary suppliers. | Dynamic and networked, where the “best” supplier for a given order is determined by real-time conditions and a holistic assessment of cost, risk, and speed. |

The goal is to transform the supplier base from a static list of vendors into a dynamic portfolio of capabilities that can be accessed on demand.

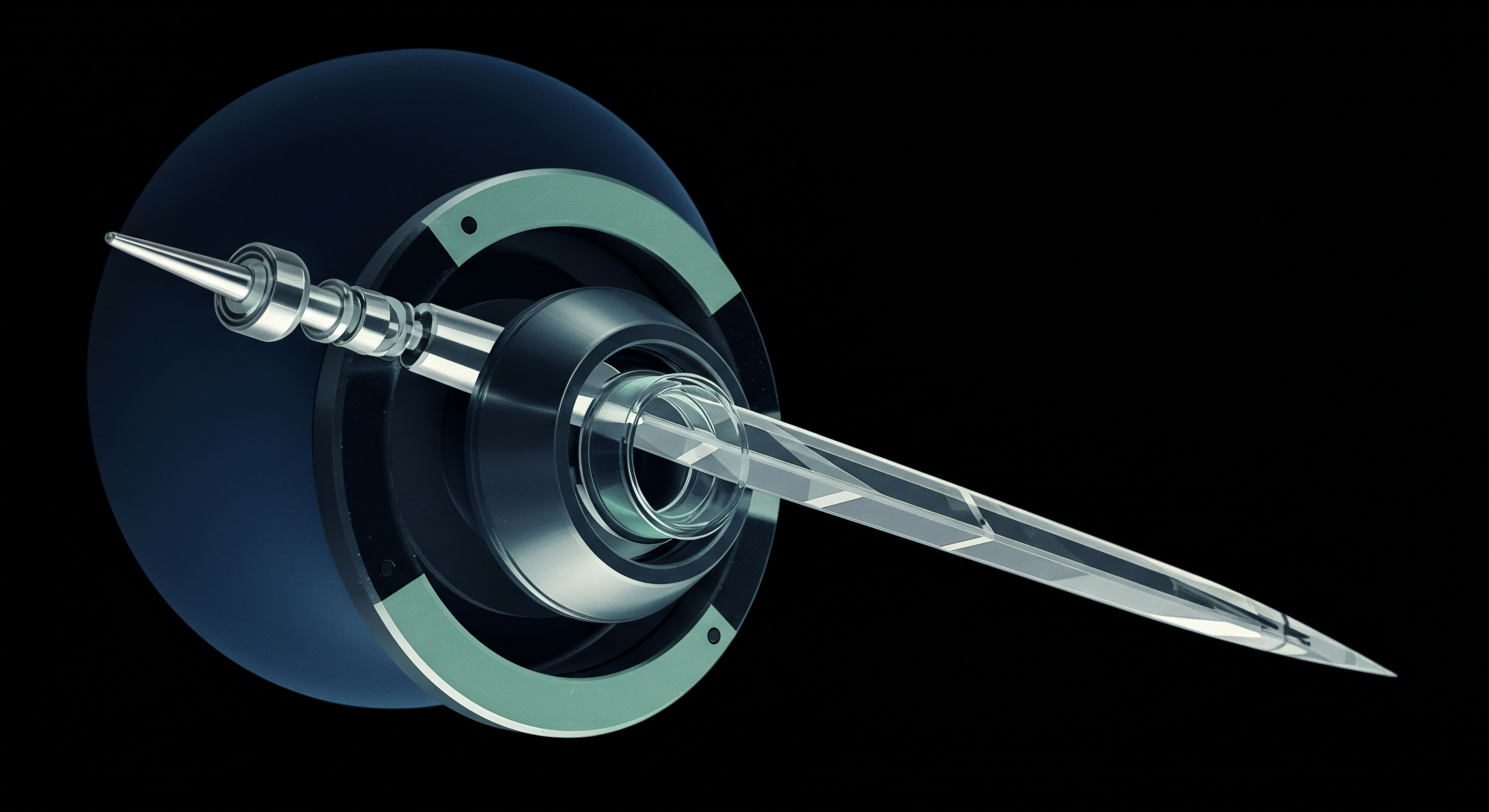

The Proactive Disruption Response Framework

With a foundation of fused data and an adaptive supplier network, the final strategic element is a formal framework for using these capabilities to respond to disruptions. This framework ensures that the organization can move from detection to resolution in a structured, efficient, and repeatable manner. The framework consists of five phases:

- Detect ▴ The system uses AI-powered anomaly detection to monitor all integrated data streams for early warning signs of a potential disruption. This could be anything from a sudden spike in commodity prices to a dip in a key supplier’s production output. The system automatically generates an alert for the relevant stakeholders.

- Analyze ▴ Once an alert is triggered, the system’s analytical tools are used to assess the potential impact of the disruption. The “digital twin” is used to model the ripple effects throughout the supply chain, identifying which products, production lines, and customers will be affected.

- Model ▴ The system then generates a set of potential solutions. This involves automatically identifying alternative suppliers from the pre-vetted pool, calculating new lead times and costs, and modeling the outcomes of different sourcing scenarios. This provides decision-makers with a menu of viable options.

- Act ▴ With a clear understanding of the options, the procurement team uses the RFP system to execute the chosen response. This could involve issuing an emergency RFP to a group of alternative suppliers, re-allocating inventory, or adjusting production schedules. The system’s automation capabilities ensure that this can be done in minutes, not days.

- Learn ▴ After the disruption has been resolved, all data related to the event ▴ from the initial alert to the final outcome ▴ is stored and used to train the system’s AI models. This ensures that the system becomes more intelligent and effective at detecting and responding to similar events in the future. This continuous learning loop is what drives long-term resilience.

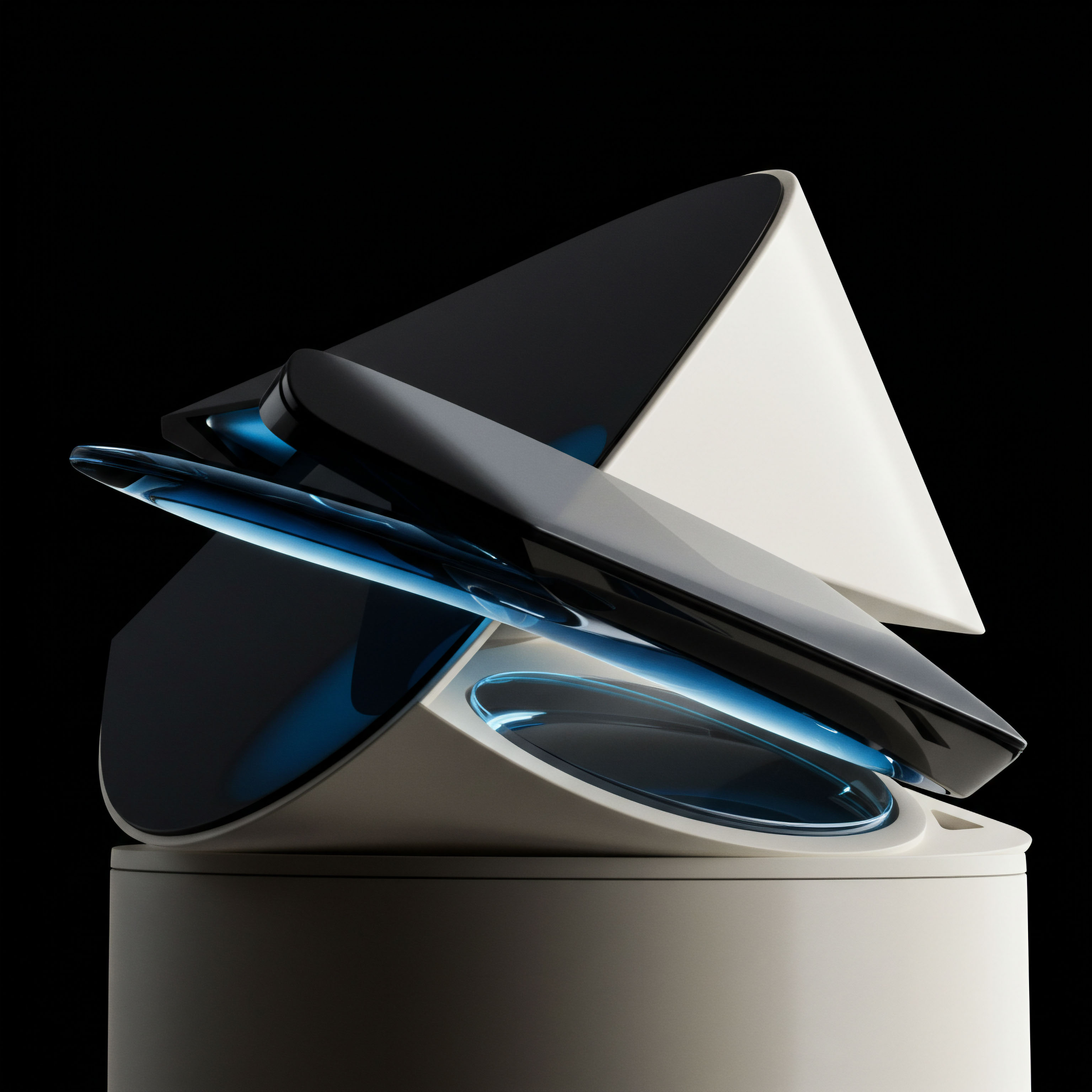

Execution

The execution of a supply chain disruption response using a real-time RFP system is a high-stakes, time-sensitive operation. It demands a clear playbook, robust analytical models, and a well-defined technological architecture. This is where strategy is translated into decisive action.

Success is measured in minutes and precision, moving the organization from a state of vulnerability to one of control. The focus here is on the granular, procedural steps and quantitative frameworks that enable a rapid and effective response to an unforeseen event.

The Operational Playbook for Disruption Response

When a critical disruption occurs, a well-defined operational playbook is essential. The following is a step-by-step procedural guide for a hypothetical scenario in which a key Tier 1 supplier of custom microprocessors, “Innovate Circuits,” located in a region experiencing sudden political instability, goes offline.

- Automated Alert Trigger ▴ The system, monitoring geopolitical news feeds and logistics provider updates, flags the disruption. An automated alert is immediately sent to the Head of Procurement, the Supply Chain Risk Manager, and the Product Line Manager for all products using Innovate Circuits’ components. The alert includes a preliminary impact assessment, listing the specific part numbers and finished goods affected.

- Convene the Rapid Response Team ▴ The recipients of the alert form a virtual rapid response team. Their first action is to access the shared “Disruption Dashboard” within the RFP system, which provides a single source of truth for all information related to the event.

- Quantify the Immediate Impact ▴ Using the system’s “Bill of Materials (BOM) Explosion” feature, the team instantly determines the exact quantity of on-hand and in-transit inventory for the affected microprocessors. They cross-reference this with the production schedule from the integrated ERP system to calculate the precise “time-to-shutdown” for each affected production line.

- Activate Contingency Sourcing Protocol ▴ The Supply Chain Risk Manager initiates the “Contingency Sourcing Protocol” within the RFP system. The system automatically generates a list of pre-qualified alternative suppliers for the affected microprocessors, ranked by a composite “Viability Score” based on historical performance, current capacity, and location.

- Issue a Real-Time RFP ▴ The Head of Procurement uses a pre-built template to launch an emergency RFP to the top three ranked alternative suppliers. The RFP includes the detailed technical specifications of the component, the required delivery schedule, and a request for pricing at various volume breaks. The system’s real-time communication portal allows for immediate clarification of any questions from the potential suppliers.

- Analyze Bids and Award Contract ▴ As bids are received, the system automatically normalizes the data, presenting a side-by-side comparison of total landed cost, lead time, and any deviations from the requested specifications. The system also runs a simulation of the impact of each bid on the production schedule and profit margins. Based on this analysis, the team awards the contract to the supplier that offers the optimal balance of speed and cost.

- Update System of Record ▴ Once the contract is awarded, the RFP system automatically updates the ERP with the new supplier information, purchase order details, and expected delivery dates. This ensures that the entire organization is working from the most current information.

Quantitative Modeling and Data Analysis

At the heart of the “Act” phase is a robust quantitative model for evaluating alternative suppliers. The “Supplier Risk & Viability Matrix” is a powerful tool for this purpose. It uses a weighted scoring model to provide an objective, data-driven assessment of the available options. The following table provides a simplified example of this matrix in action during our hypothetical disruption.

| Metric (Weight) | Supplier A (Stratex Inc.) | Supplier B (Global Components) | Supplier C (NextGen Chips) |

|---|---|---|---|

| Real-Time Cost Quote (30%) | $12.50/unit (Score ▴ 8/10) | $11.90/unit (Score ▴ 10/10) | $13.10/unit (Score ▴ 7/10) |

| Quoted Lead Time (30%) | 7 days (Score ▴ 9/10) | 12 days (Score ▴ 6/10) | 6 days (Score ▴ 10/10) |

| Available Capacity (20%) | 150,000 units/week (Score ▴ 10/10) | 120,000 units/week (Score ▴ 8/10) | 90,000 units/week (Score ▴ 6/10) |

| Quality Score (15%) | 99.8% yield (Score ▴ 10/10) | 99.5% yield (Score ▴ 9/10) | 99.2% yield (Score ▴ 8/10) |

| Geopolitical Risk (5%) | Low (Score ▴ 9/10) | Low (Score ▴ 9/10) | Moderate (Score ▴ 5/10) |

| Weighted Score | 9.25 | 8.55 | 7.90 |

In this model, each metric is assigned a weight based on its strategic importance. While Supplier B offers the lowest price, its longer lead time makes it a less attractive option in this time-sensitive scenario. Supplier C is the fastest but has limited capacity and a higher price.

Supplier A, despite not being the best in any single category, emerges as the optimal choice due to its balanced performance across all critical metrics. This type of quantitative analysis removes emotion and guesswork from the decision-making process, ensuring that the chosen path is the most logical and defensible one.

Predictive Scenario Analysis a Case Study

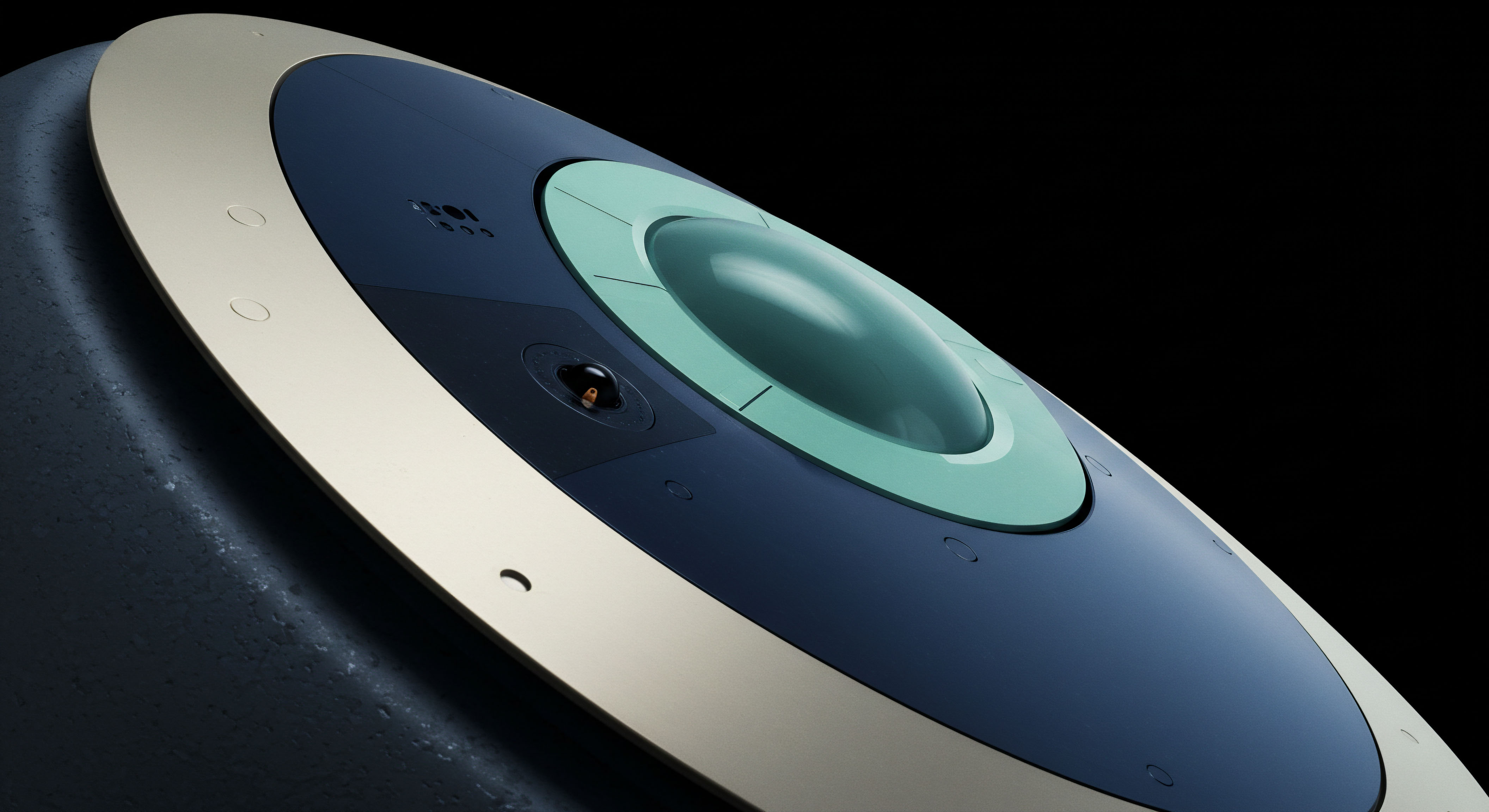

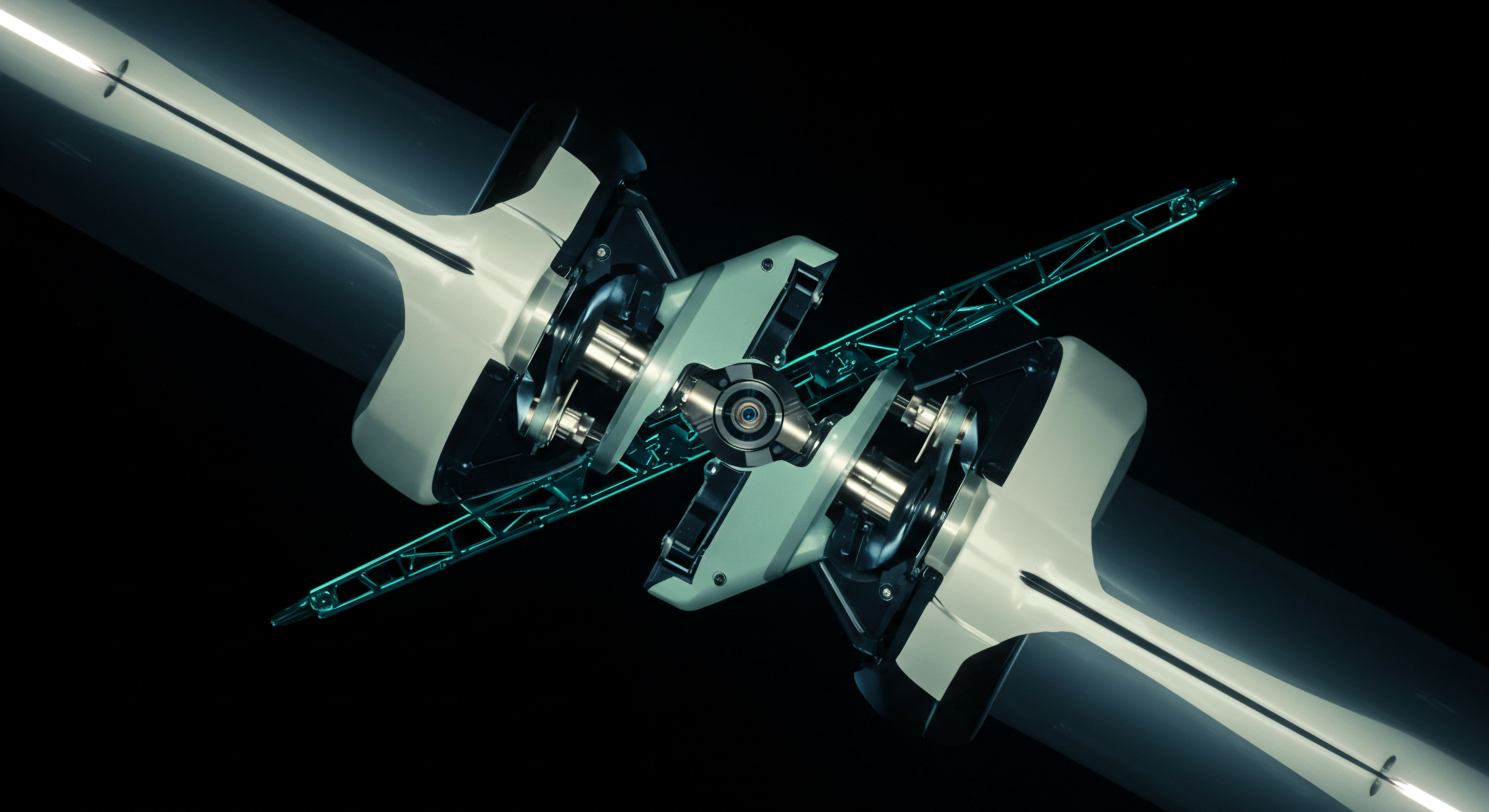

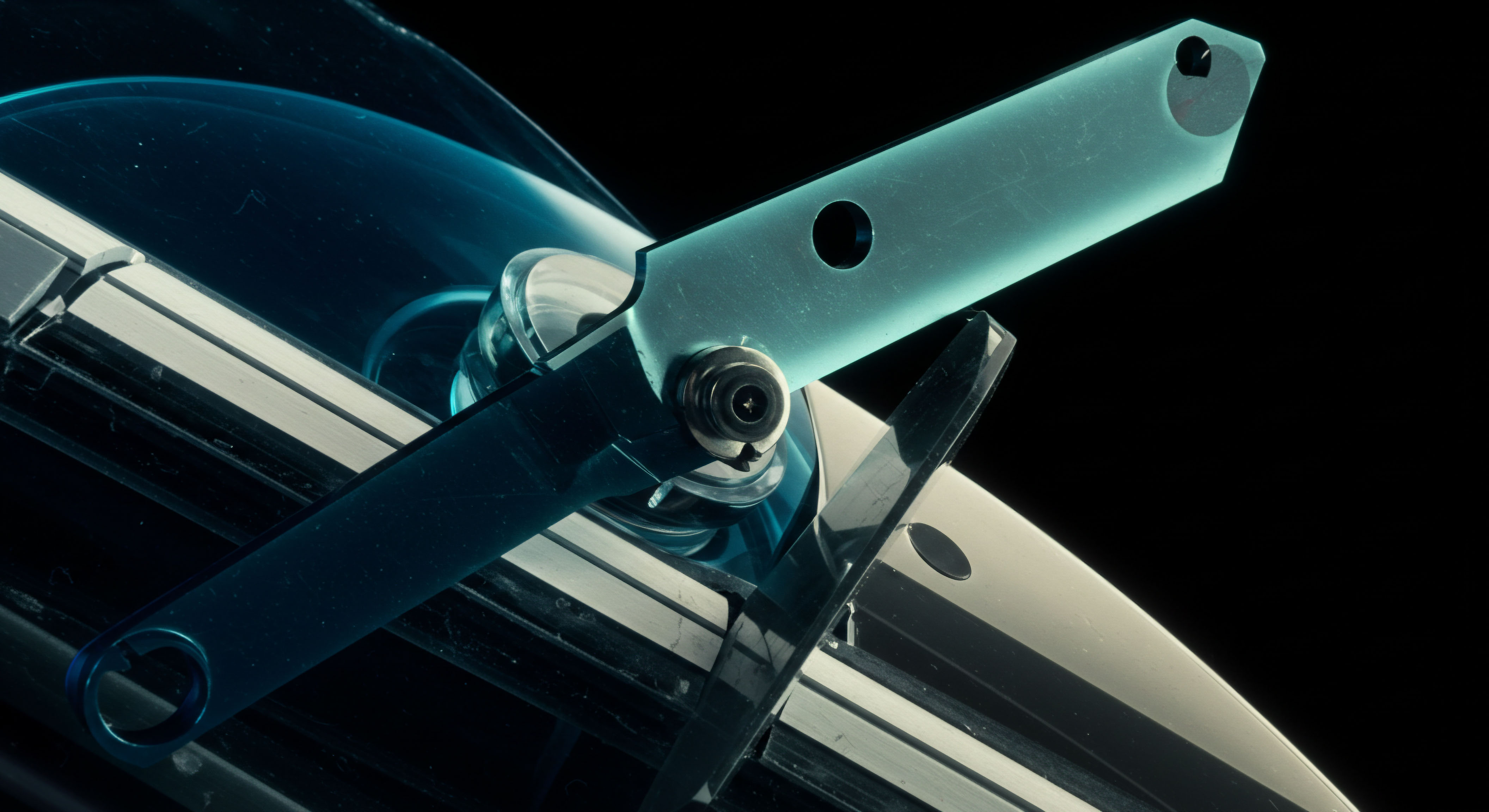

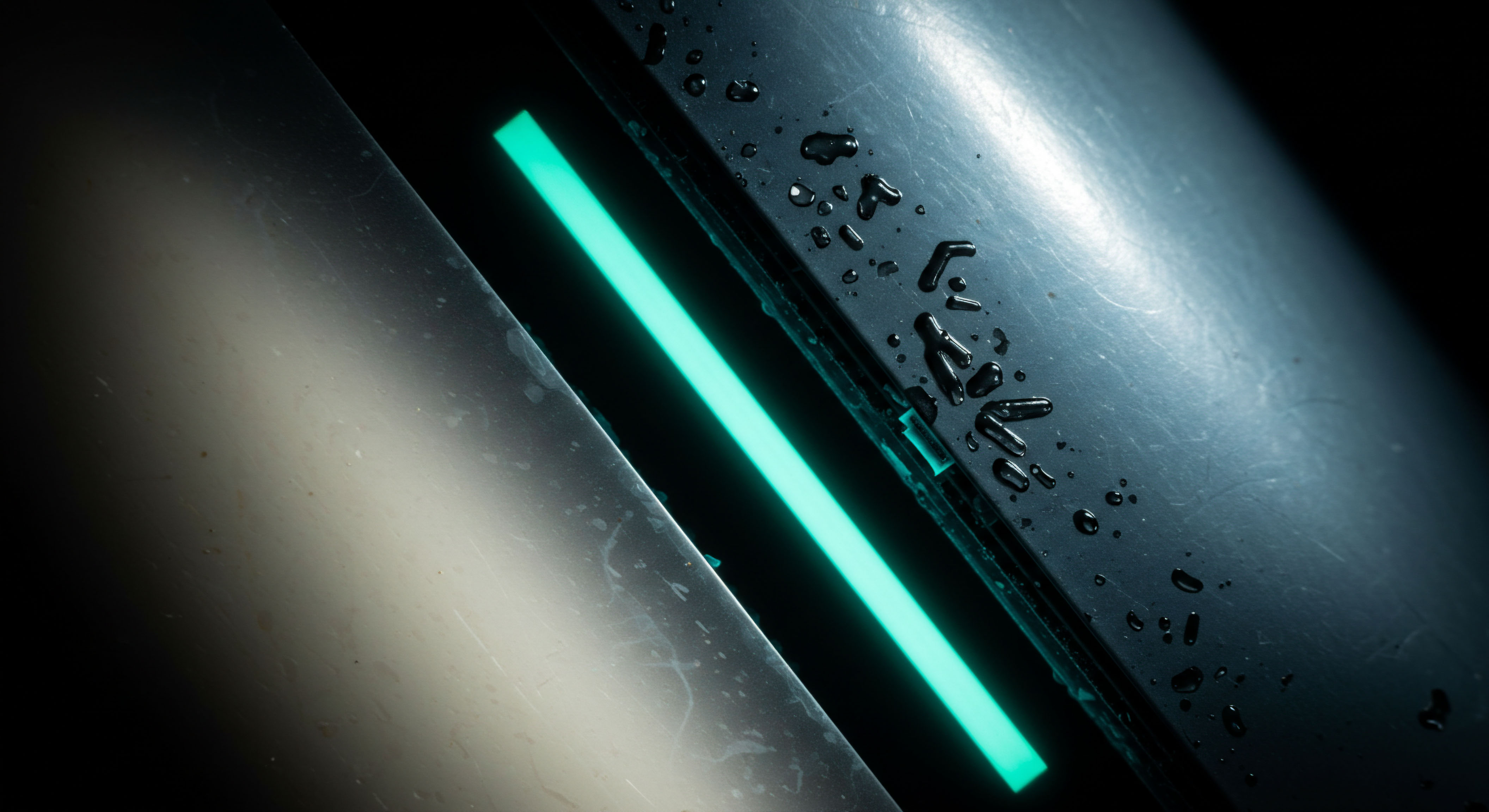

Aperture Robotics, a manufacturer of high-end autonomous drones, faced a crisis when a fire at a major semiconductor fabrication plant disrupted the supply of a critical guidance chip. Their legacy system would have meant weeks of scrambling, contacting suppliers manually, and likely a costly production shutdown. However, their recently implemented real-time RFP system, integrated with their ERP and market intelligence feeds, initiated a different sequence of events. The system immediately flagged the disruption from news sources and cross-referenced the affected plant with its supplier database.

Within an hour, the procurement team had a full impact analysis ▴ 3,200 drones in the current production run were affected, with on-hand inventory sufficient for only four days of production. The system automatically identified two pre-qualified alternative suppliers in different geographic regions. An emergency RFP was dispatched, and within six hours, both suppliers had responded with detailed quotes and capacity commitments. The system’s modeling engine projected that by splitting the order between the two new suppliers and expediting shipping for the first batch, the production line would only need to be halted for a single shift.

The total cost of the mitigation ▴ including higher component prices and expedited freight ▴ was calculated at $450,000. The cost of a two-week shutdown, by contrast, was projected to be over $3 million in lost revenue and contractual penalties. The decision was clear. The team executed the split purchase order directly through the system, and the crisis was averted. This case demonstrates the immense value of speed and data-driven modeling in a real-world disruption.

System Integration and Technological Architecture

The effectiveness of this entire process is contingent on a seamless technological architecture. The real-time RFP system does not operate in a vacuum. It must be tightly integrated with the organization’s other core enterprise systems to enable the free flow of information. The essential integration points are:

- Enterprise Resource Planning (ERP) ▴ This is the most critical integration. The RFP system needs to pull demand forecasts, production schedules, inventory levels, and bill of materials data from the ERP. In turn, it needs to push purchase order information, new supplier data, and updated lead times back into the ERP.

- Transportation Management System (TMS) ▴ Integration with the TMS provides the RFP system with real-time data on shipping lanes, carrier availability, and freight costs. This allows for more accurate calculation of total landed cost and realistic delivery timelines.

- Supplier Relationship Management (SRM) ▴ The RFP system can feed performance data into the SRM, providing a more holistic view of supplier relationships. This includes metrics on responsiveness, pricing competitiveness, and reliability during disruptions.

- External Data Feeds ▴ APIs are used to connect the RFP system to a wide range of external data sources. These can include commodity market trackers, financial news services, geopolitical risk analysis providers, and even weather forecasting services. This external context is what enables the system’s predictive capabilities.

References

- Alonge, Enoch Oluwabusayo, et al. “Real-Time Data Analytics for Enhancing Supply Chain Efficiency.” International Journal of Multidisciplinary Research and Growth Evaluation, vol. 2, no. 1, 2021, pp. 759-771.

- Baryannis, George, et al. “An artificial intelligence-based framework for supply chain disruption prediction.” The International Journal of Advanced Manufacturing Technology, vol. 101, 2019, pp. 1917-1933.

- Christopher, Martin. Logistics & Supply Chain Management. 5th ed. Pearson, 2016.

- Dubey, Rameshwar, et al. “Big data analytics and organizational culture as complements to fast-track supply chain resilience.” Supply Chain Management ▴ An International Journal, vol. 26, no. 6, 2021, pp. 745-760.

- Frohlich, Markham T. “e-Integration in the Supply Chain ▴ Barriers and Performance.” Decision Sciences, vol. 33, no. 4, 2002, pp. 537-556.

- Manners-Bell, John. Supply Chain Risk Management ▴ A Comprehensive Guide to Identifying, Assessing, and Mitigating Threats. 4th ed. Kogan Page, 2023.

- Schoenherr, Tobias, and V.M. Rao Tummala. “Electronic procurement ▴ a structured literature review and directions for future research.” International Journal of Procurement Management, vol. 1, no. 1-2, 2007, pp. 8-37.

- Waters, Donald. Supply Chain Risk Management ▴ Vulnerability and Resilience in Logistics. 2nd ed. Kogan Page, 2011.

Reflection

The Resilient System’s Mandate

The integration of real-time data into the core of procurement is an architectural evolution. It signals a fundamental shift in how an organization perceives and interacts with its external environment. The frameworks and technologies discussed are components of a larger system, an organizational intelligence apparatus designed to process volatility into opportunity. The true measure of this system is not its response to a single crisis, but its ability to embed resilience into the very fabric of daily operations.

The ultimate objective is a state of persistent readiness, where the capacity to adapt is so deeply ingrained that disruptions lose their power to derail strategic intent. This capability redefines an organization’s relationship with risk, transforming it from a hazard to be avoided into a known variable to be managed with precision and confidence.

Glossary

Supply Chain

Supply Chain Resilience

Real-Time Data

Rfp System

Supplier Network

Proactive Disruption Response

Adaptive Supplier Network

Data Streams

Logistics Data

Risk Management

System Automatically

Alternative Suppliers