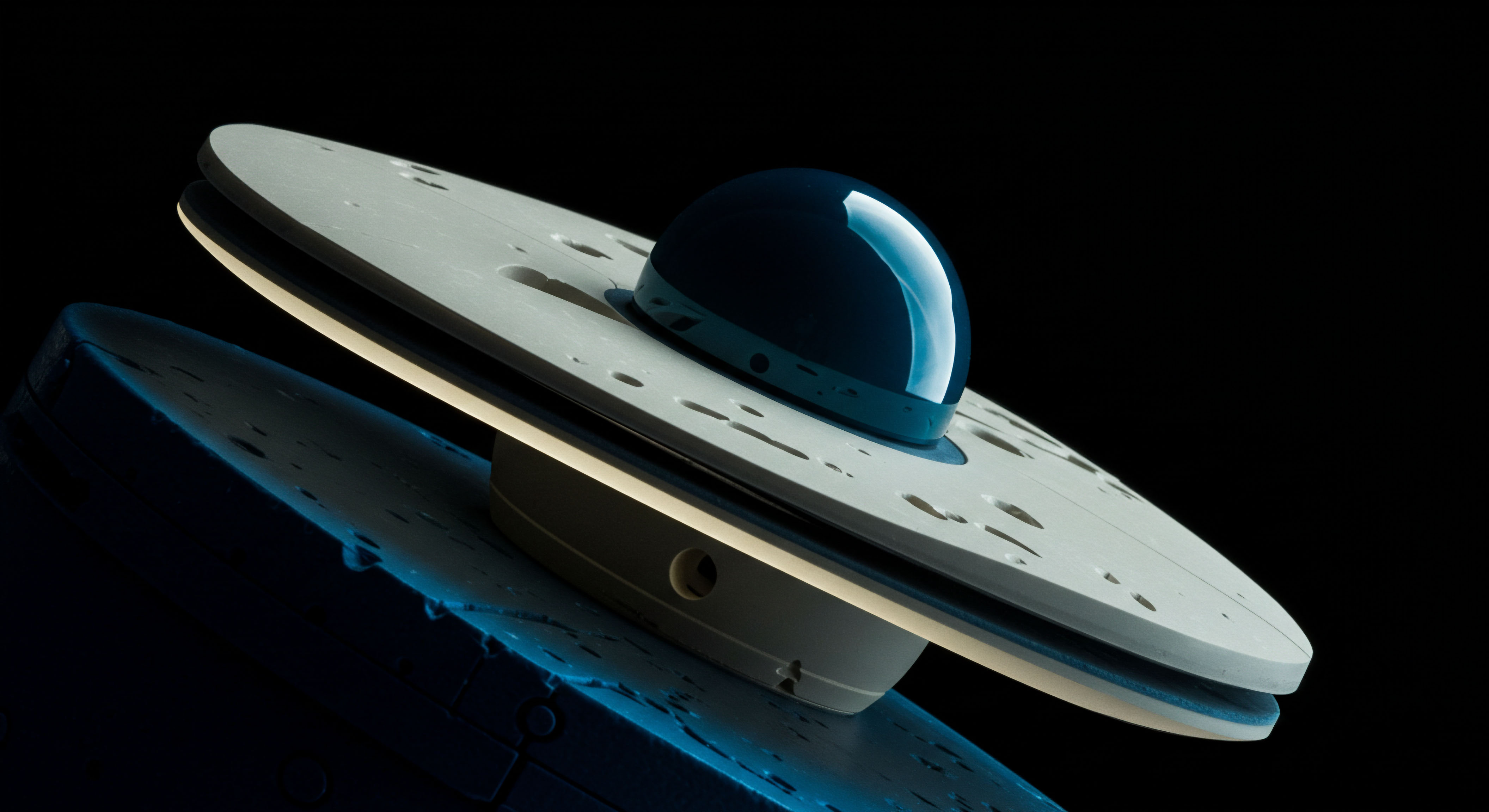

Concept

The conclusion of a multi-stage procurement process represents a point of significant investment in capital, time, and human resources. A pervasive fallacy in many organizations is to view the signed contract as the finish line. This perspective fundamentally misunderstands the nature of value creation. The contract is not the prize; it is the starting block.

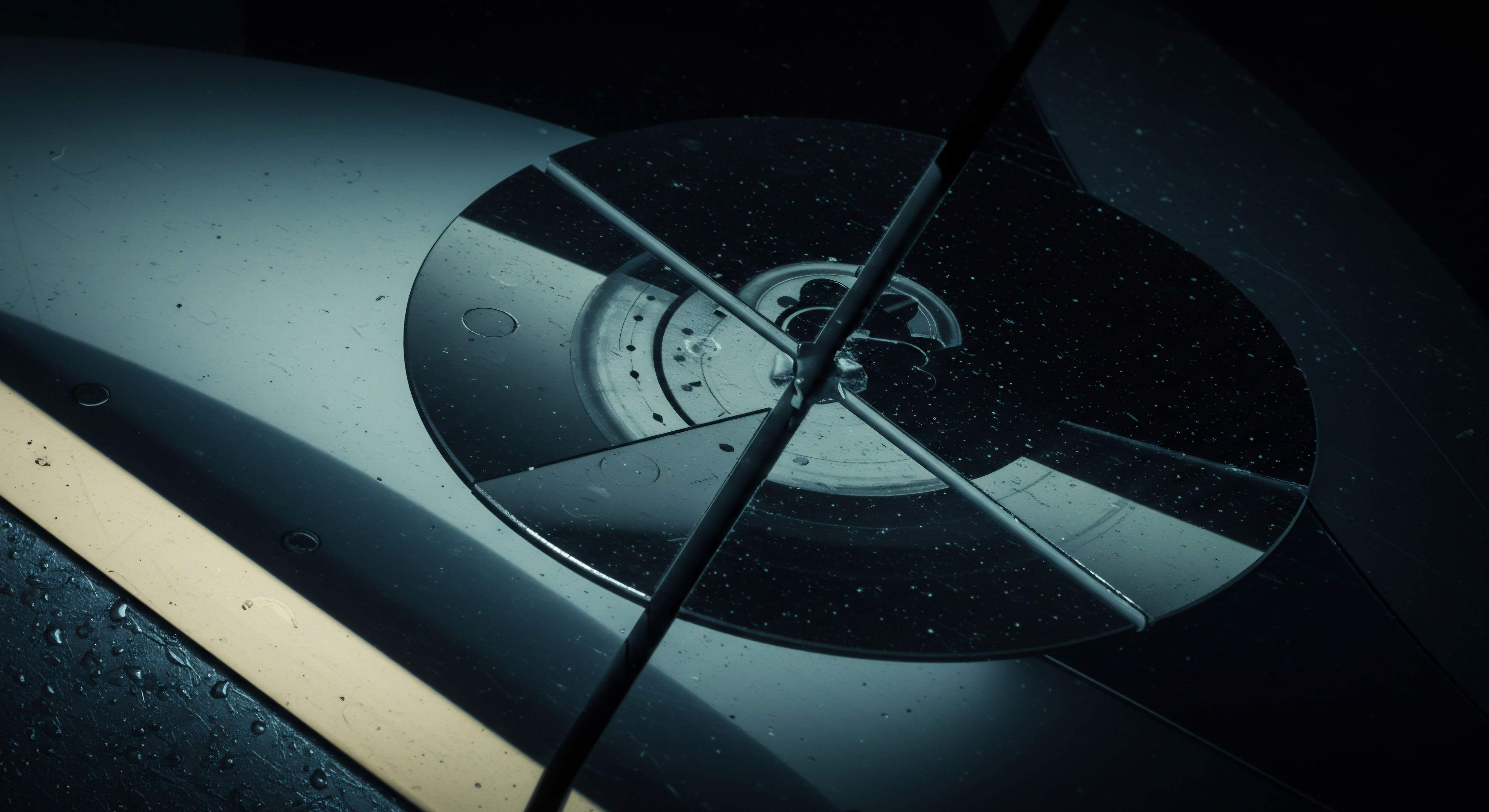

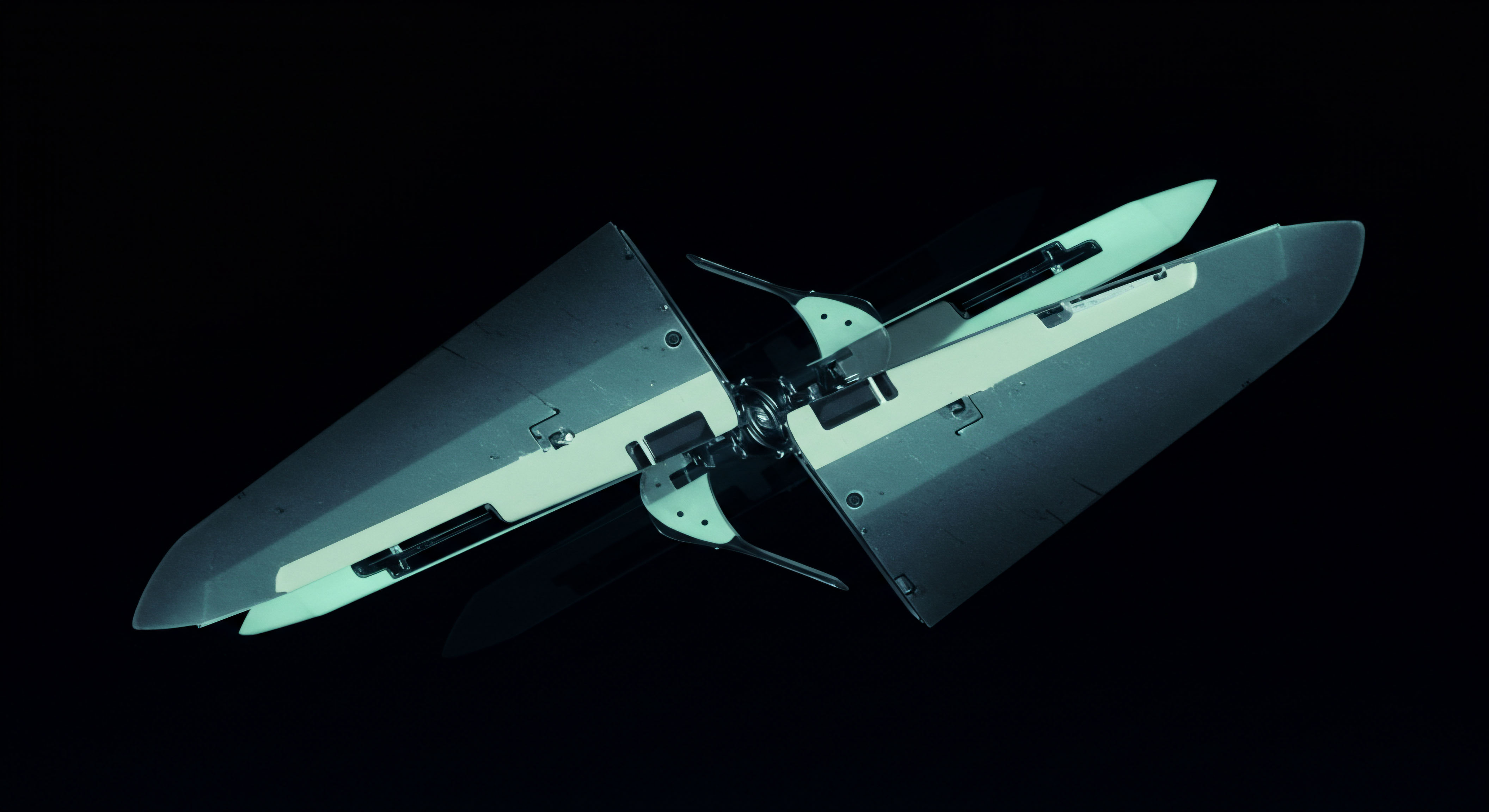

The real work begins after the ink has dried, and the potential for value erosion or creation accelerates dramatically in the post-procurement phase. Managing the ensuing supplier relationship is an exercise in activating a newly acquired strategic asset. Failing to do so with systemic rigor is equivalent to purchasing a high-performance engine and leaving it disconnected from the drivetrain.

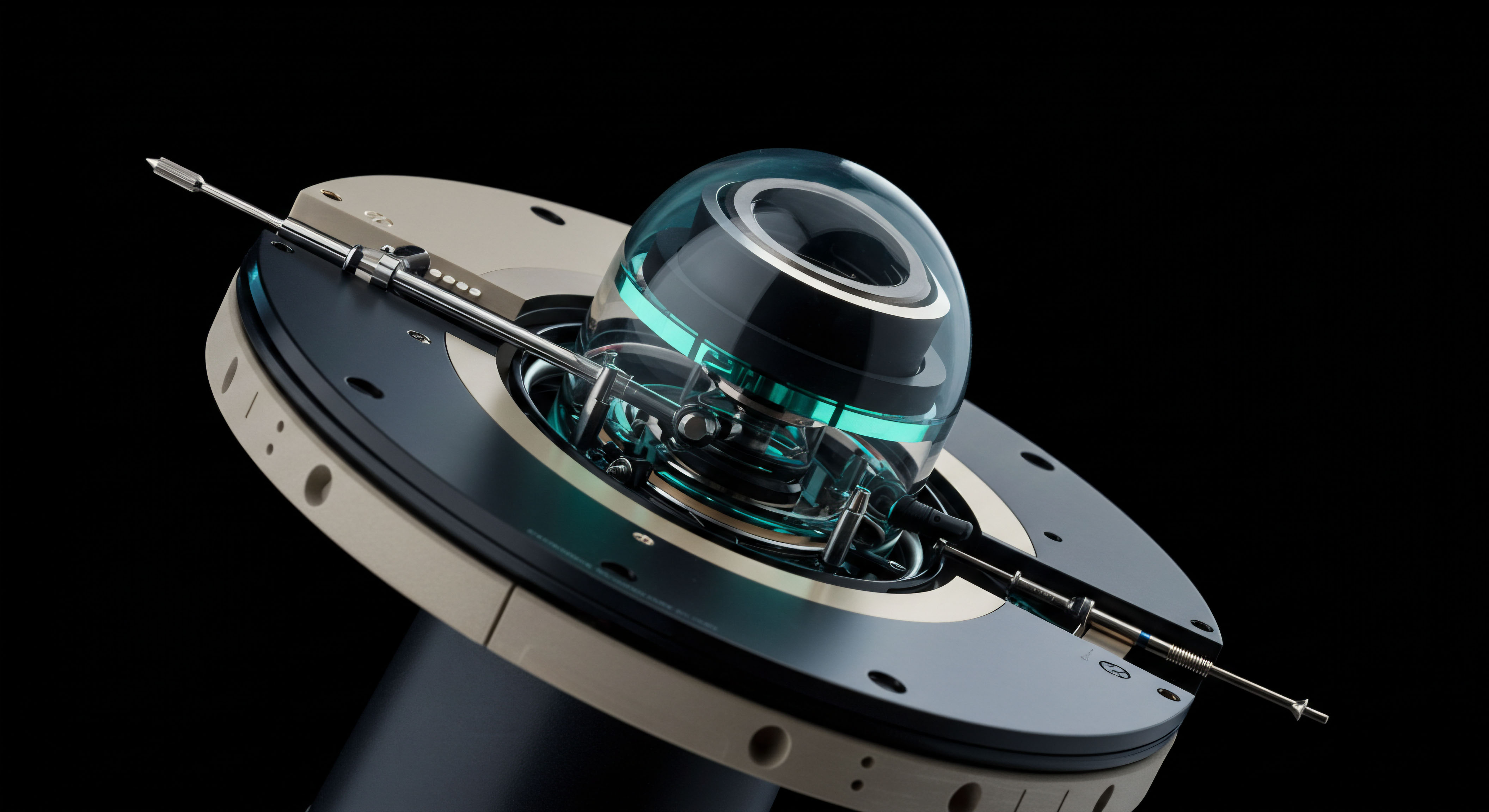

Effective post-procurement supplier relationship management (SRM) is a disciplined, system-oriented function designed to achieve three primary objectives ▴ continuous value realization, proactive risk mitigation, and collaborative growth. It moves the dynamic from a purely transactional exchange to a managed, strategic partnership. This requires a purpose-built operational framework, not an ad-hoc series of meetings and escalations.

The foundation of this framework rests on transforming ambiguous expectations into quantifiable, transparent, and mutually understood metrics. The process establishes clear guidelines for performance, communication, and governance, ensuring that the value proposition identified during the intensive procurement cycle is consistently delivered and expanded upon throughout the contract lifecycle.

A robust supplier relationship management program transforms a static contractual agreement into a dynamic, value-generating operational system.

The architecture of this system is built upon several core pillars. First, a clear segmentation of the supplier base allows for the strategic allocation of management resources. Not all suppliers carry the same strategic weight, and applying a uniform management approach is inefficient and ineffective. Second, a robust performance management protocol translates business objectives into specific, measurable supplier key performance indicators (KPIs).

This provides an objective basis for performance evaluation and continuous improvement. Third, a comprehensive risk management structure identifies and mitigates potential points of failure before they can impact operations. Finally, defined communication and governance cadences ensure that information flows efficiently, and that both parties are aligned at the operational and strategic levels. This systemic approach ensures that the relationship becomes a source of resilience and competitive advantage.

Strategy

Developing a potent strategy for post-procurement supplier management requires a deliberate move away from a one-size-fits-all mentality. The core of an effective SRM strategy is supplier segmentation, a method for categorizing suppliers to apply the appropriate level of managerial oversight and collaborative investment. The Kraljic Matrix is a foundational tool for this purpose, classifying suppliers along two axes ▴ profit impact and supply risk. This segmentation creates a clear blueprint for where to focus the most intensive relationship management efforts, ensuring that resources are deployed with maximum effect.

A Framework for Supplier Segmentation

The segmentation process results in four distinct supplier categories, each demanding a unique strategic approach. Mismanaging a supplier by placing them in the wrong quadrant ▴ for instance, treating a strategic supplier with a transactional approach ▴ is a common and costly error. The correct classification is the first step in aligning strategy with operational reality.

- Strategic Suppliers (High Profit Impact, High Supply Risk) ▴ These are partners in the truest sense. They are critical to the organization’s own product or service and often operate in a market with few alternatives. The strategy here is one of deep collaboration, joint business planning, executive-level engagement, and co-investment in technology and innovation. The relationship is a long-term alliance designed to create mutual competitive advantage.

- Leverage Suppliers (High Profit Impact, Low Supply Risk) ▴ These suppliers provide important components or services but operate in a competitive marketplace with many substitutes. The strategic focus is on optimizing value. This involves using competitive bidding, negotiating favorable terms, and consolidating spend to maximize purchasing power. While the relationship is professional, the primary driver is commercial advantage.

- Bottleneck Suppliers (Low Profit Impact, High Supply Risk) ▴ These suppliers provide items that may be low in value but are essential for operations, and for which there are few, if any, alternative sources. A disruption from a bottleneck supplier can halt production. The strategy is centered on ensuring supply continuity. This includes holding safety stock, developing long-term contracts, and actively seeking alternative or substitute materials to reduce dependency.

- Non-Critical Suppliers (Low Profit Impact, Low Supply Risk) ▴ This category includes suppliers of routine, low-value items in a competitive market. The strategy is to maximize efficiency. This means automating the procurement process as much as possible, using standardized products, and minimizing the human effort involved in managing these transactions.

| Supplier Segment | Core Characteristic | Primary Strategic Goal | Key Management Activities |

|---|---|---|---|

| Strategic | High value, high dependency | Maximize Collaboration & Innovation | Joint business planning, executive sponsorship, shared technology roadmaps, co-creation |

| Leverage | High value, low dependency | Optimize Total Cost of Ownership | Competitive bidding, volume consolidation, negotiation, market analysis |

| Bottleneck | Low value, high dependency | Ensure Supply Continuity | Risk mitigation plans, long-term contracts, inventory management, develop alternatives |

| Non-Critical | Low value, low dependency | Maximize Process Efficiency | E-procurement platforms, standardized catalogs, automated ordering, minimal oversight |

Designing the Governance and Performance Engine

Once suppliers are segmented, a corresponding governance structure must be implemented. A strategic supplier might require quarterly business reviews (QBRs) attended by C-level executives from both companies, while a non-critical supplier’s performance might be monitored entirely through automated system reports. This tiered governance model ensures that attention is focused where it matters most.

Aligning governance intensity with supplier segmentation prevents resource waste and focuses strategic attention on the relationships that drive the most value.

The heart of this governance is the supplier performance management system. This is not merely about tracking delivery times; it is about creating a balanced scorecard that reflects the total value of the relationship. This scorecard should be developed collaboratively with key suppliers to ensure buy-in and a shared understanding of what success looks like.

It forms the objective basis for performance discussions, contract renewals, and continuous improvement initiatives. The data from these scorecards feeds back into the overall SRM strategy, allowing for dynamic adjustments and a clear, data-driven view of the health of the entire supply base.

Execution

The translation of SRM strategy into operational reality is where value is ultimately secured. This requires a granular, process-driven approach that embeds the principles of performance management, risk mitigation, and collaboration into the daily workflows of the organization. The execution phase is a continuous cycle of measurement, analysis, and interaction, supported by a robust technological backbone.

The Operational Playbook for Supplier Onboarding and Integration

A structured onboarding process is fundamental to setting the tone for the entire relationship. It ensures that the transition from procurement to operations is seamless and that the supplier is fully integrated into the organization’s systems and processes from day one.

- Formal Kick-Off and Alignment ▴ Within two weeks of contract signing, a formal meeting should occur. This involves key stakeholders from both organizations. The agenda covers a review of the contract’s key terms, the establishment of communication protocols, an introduction to the governance structure, and a detailed walkthrough of the supplier performance scorecard.

- Systems and Data Integration ▴ This technical step involves connecting the supplier to the necessary internal platforms. This could range from simple portal access for invoice submission to deep API integration between the supplier’s manufacturing execution system (MES) and the buyer’s enterprise resource planning (ERP) system for real-time visibility into production and inventory levels.

- Establishment of Communication Cadence ▴ The playbook defines the “who, what, when, and how” of communication. This includes scheduling regular operational check-ins (e.g. weekly), tactical performance reviews (e.g. monthly), and strategic business reviews (e.g. quarterly for strategic partners). Each meeting type has a standard agenda and defined attendees.

- Deployment of the Performance Scorecard ▴ The collaboratively developed scorecard is formally implemented. The initial performance period (e.g. the first quarter) is often treated as a baseline period, allowing for calibration and adjustment of the metrics and targets before they are tied to any performance-based incentives.

Quantitative Modeling and Data Analysis

Objective data is the bedrock of effective SRM execution. Moving beyond subjective assessments requires quantitative models that provide a clear and consistent view of supplier performance and total cost.

The Supplier Performance Scorecard is the primary tool for this. It must be a weighted model that reflects the specific priorities of the business for that supplier category. For a strategic supplier, innovation and quality might carry the highest weights; for a leverage supplier, cost and on-time delivery might be paramount.

| Category (Weight) | KPI | Target | Actual | Score (Actual/Target Weight) |

|---|---|---|---|---|

| Quality (30%) | Defect Rate (PPM) | < 500 | 450 | 30.0 |

| Delivery (25%) | On-Time In-Full (OTIF) | > 99% | 99.5% | 25.0 |

| Cost (20%) | Year-over-Year Cost Reduction | 3% | 3.5% | 20.0 |

| Innovation (15%) | Number of Process Improvement Proposals | 4 | 5 | 15.0 |

| Risk & Compliance (10%) | Audit Compliance Score | 100% | 100% | 10.0 |

| Total Score | 100.0 |

It is tempting to believe that a quantitative scorecard can capture the entirety of a relationship’s value. This is a dangerous oversimplification. How does one precisely quantify the value of a supplier’s engineer proactively identifying a design flaw before it enters production? Or the value of their willingness to expedite a shipment during an unforeseen demand surge?

These collaborative and qualitative aspects are vital, particularly with strategic partners. The data from the scorecard provides the foundation for a conversation; it does not replace it. The art of execution lies in using the quantitative framework to identify trends and areas for discussion, then applying qualitative judgment and fostering a collaborative dialogue to address the underlying issues and opportunities. This prevents collapse.

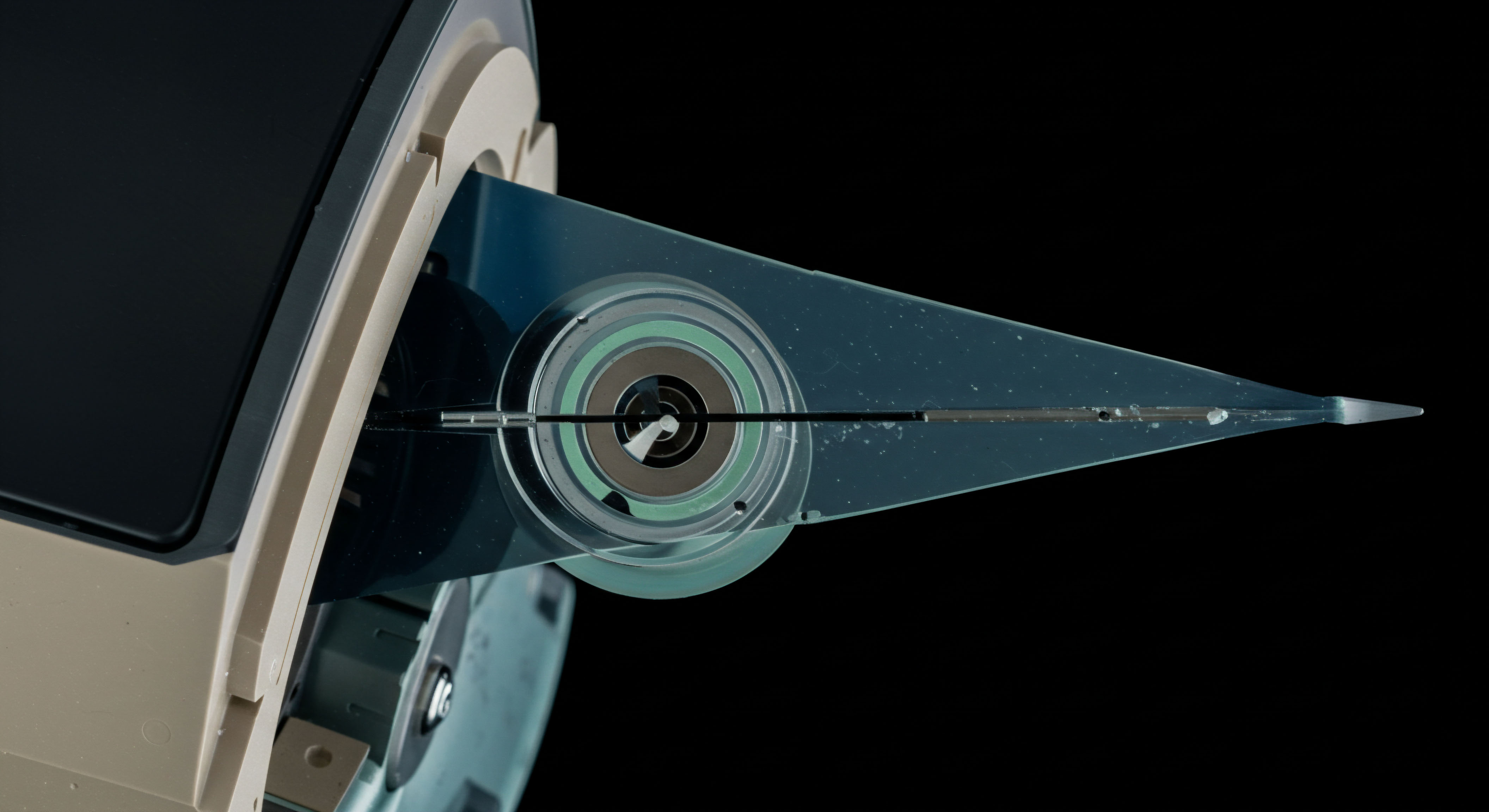

System Integration and Technological Architecture

Modern SRM cannot be run effectively on spreadsheets. A dedicated technology platform is essential for scaling the process. The ideal SRM system architecture provides a single source of truth for all supplier-related information and activities.

- A Centralized Supplier Database ▴ This contains all master data, contact information, contracts, risk profiles, and diversity certifications for every supplier.

- Contract Management Module ▴ A repository for all contracts that tracks key dates (e.g. renewal, expiration), obligations, and entitlements, and provides automated alerts.

- Performance Management Dashboards ▴ These tools automate the collection of data from various sources (e.g. ERP, quality management systems) to populate the supplier scorecards in real time. They provide at-a-glance visibility into individual supplier and aggregate supply base performance.

- Risk and Compliance Monitoring ▴ This module integrates with third-party data providers to monitor suppliers for financial distress, legal issues, sanctions list violations, and adverse media mentions, providing early warnings of potential disruptions.

- Collaboration Portals ▴ Secure online spaces where buyers and suppliers can share documents, co-manage projects, submit innovations, and resolve issues in a structured and traceable manner.

The technological framework for supplier management should automate data collection to liberate human capital for strategic analysis and relationship building.

The integration of these systems is paramount. For example, the performance data from the SRM platform should be accessible within the ERP system, so that a poor quality score for a supplier can automatically place a hold on new purchase orders until the issue is resolved. This level of system integration transforms SRM from a passive reporting function into an active, automated control mechanism that enforces compliance and protects the organization from poor performance.

References

- Handfield, R. B. Krause, D. R. Scannell, T. V. & Monczka, R. M. (2020). Avoid the Pitfalls in Supplier Development. Sloan Management Review.

- Kraljic, P. (1983). Purchasing Must Become Supply Management. Harvard Business Review.

- Lambert, D. M. & Schwieterman, M. A. (2012). Supplier relationship management as a macro business process. Supply Chain Management ▴ An International Journal, 17(3), 337-352.

- Accenture. (2021). The new era of supplier relationship management. White Paper.

- Deloitte. (2023). Global Chief Procurement Officer Survey. Report.

- Bhote, K. (1989). Strategic Supply Management ▴ A Blueprint for Revitalizing the Manufacturer-Supplier Partnership. Amacom.

- Cox, A. (2015). Sourcing and Supply Chain Management. 5th ed. Cengage Learning.

- Monczka, R. M. Handfield, R. B. Giunipero, L. C. & Patterson, J. L. (2015). Purchasing and Supply Chain Management. Cengage Learning.

From Management to Cultivation

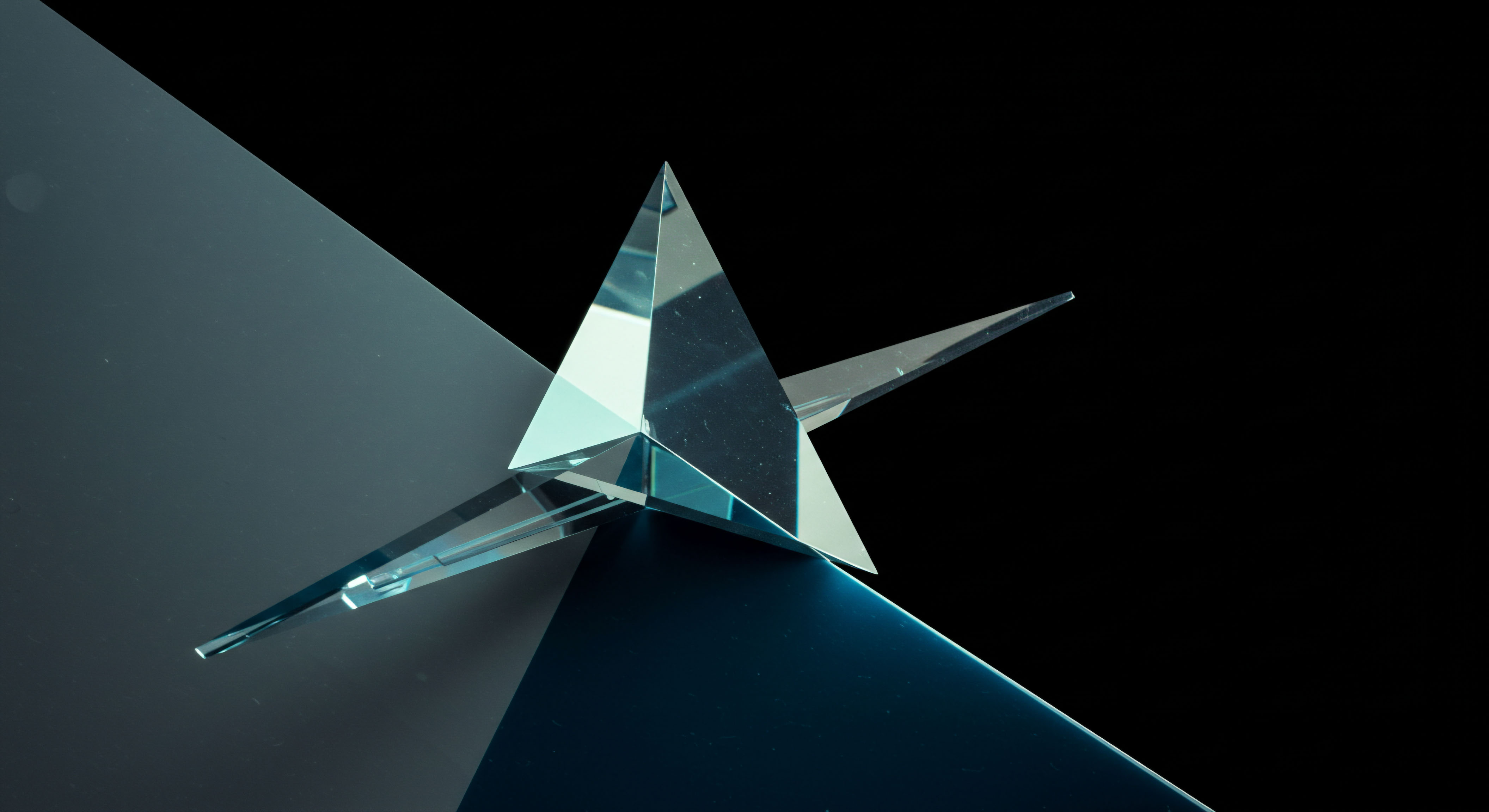

Viewing the post-procurement landscape as a system to be managed is the correct starting point. The implementation of scorecards, governance models, and technological platforms provides the necessary structure for control and efficiency. Yet, the ultimate potential of these relationships extends beyond mere management.

The most resilient and innovative supply chains are not just managed; they are cultivated. This requires a shift in perspective, viewing the supplier network as a portfolio of capabilities that can be developed and nurtured over time.

What latent innovations exist within your strategic partners that are not being accessed? How can your organization’s own processes be adapted to make it a “customer of choice,” attracting the best performance and ideas from your suppliers? The frameworks and data provide the map, but they do not dictate the destination. The true strategic advantage is found in using the intelligence gathered from these systems to ask deeper questions, to foster genuine partnership, and to build a supply ecosystem that is not only efficient and low-risk but also adaptive, resilient, and a source of continuous, collaborative growth.

Glossary

Supplier Relationship

Supplier Relationship Management

Performance Management

Relationship Management

Supplier Segmentation

Strategic Supplier

Profit Impact

Tiered Governance Model

Supplier Performance

Supplier Performance Scorecard