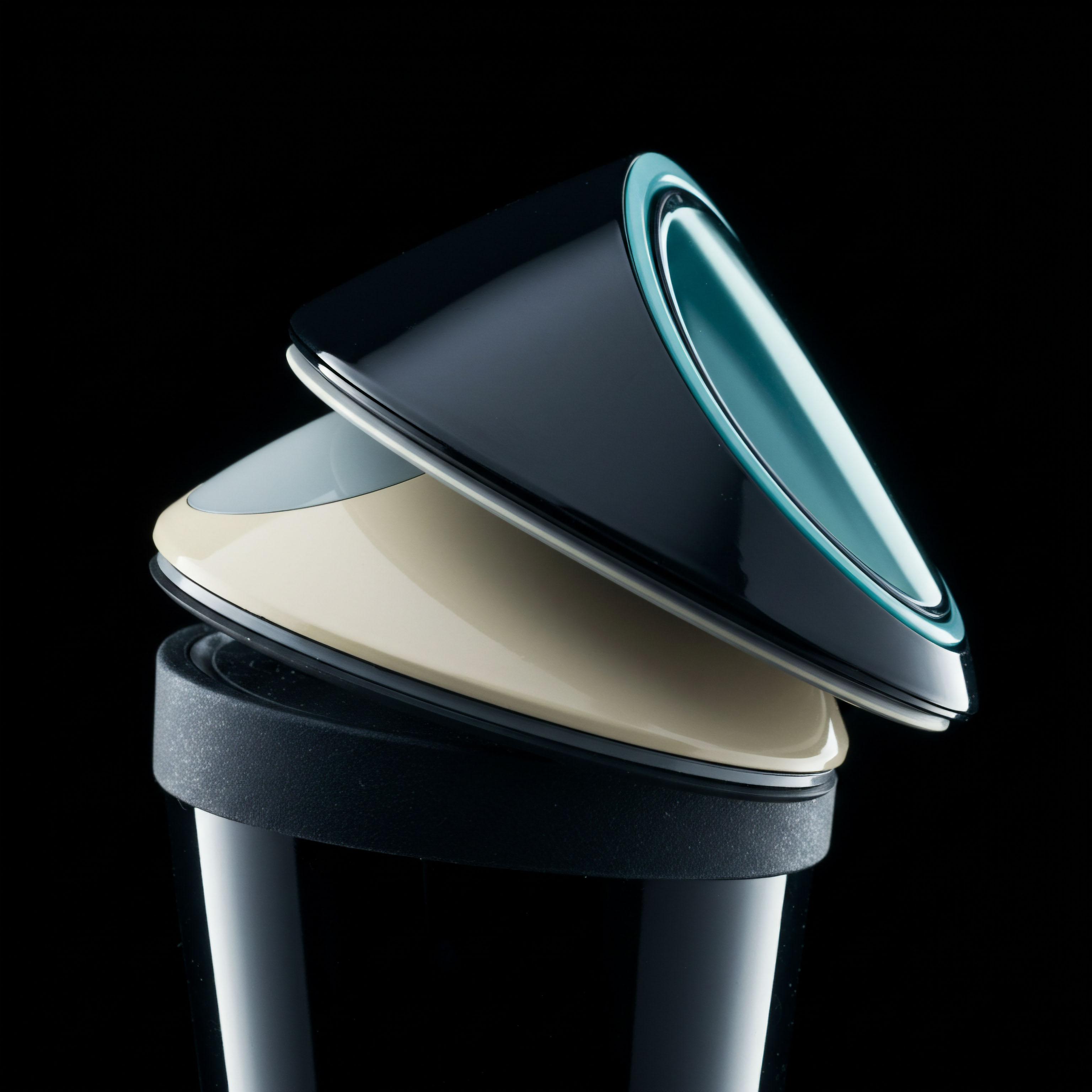

Concept

A Systemic View of Supplier Relationships

Viewing supplier relationship quality exclusively through the lens of cost reduction or on-time delivery is a fundamental misreading of its systemic importance. A supplier network is an externalized component of an organization’s operational capacity. The quality of those relationships dictates the resilience, agility, and innovative potential of the entire enterprise.

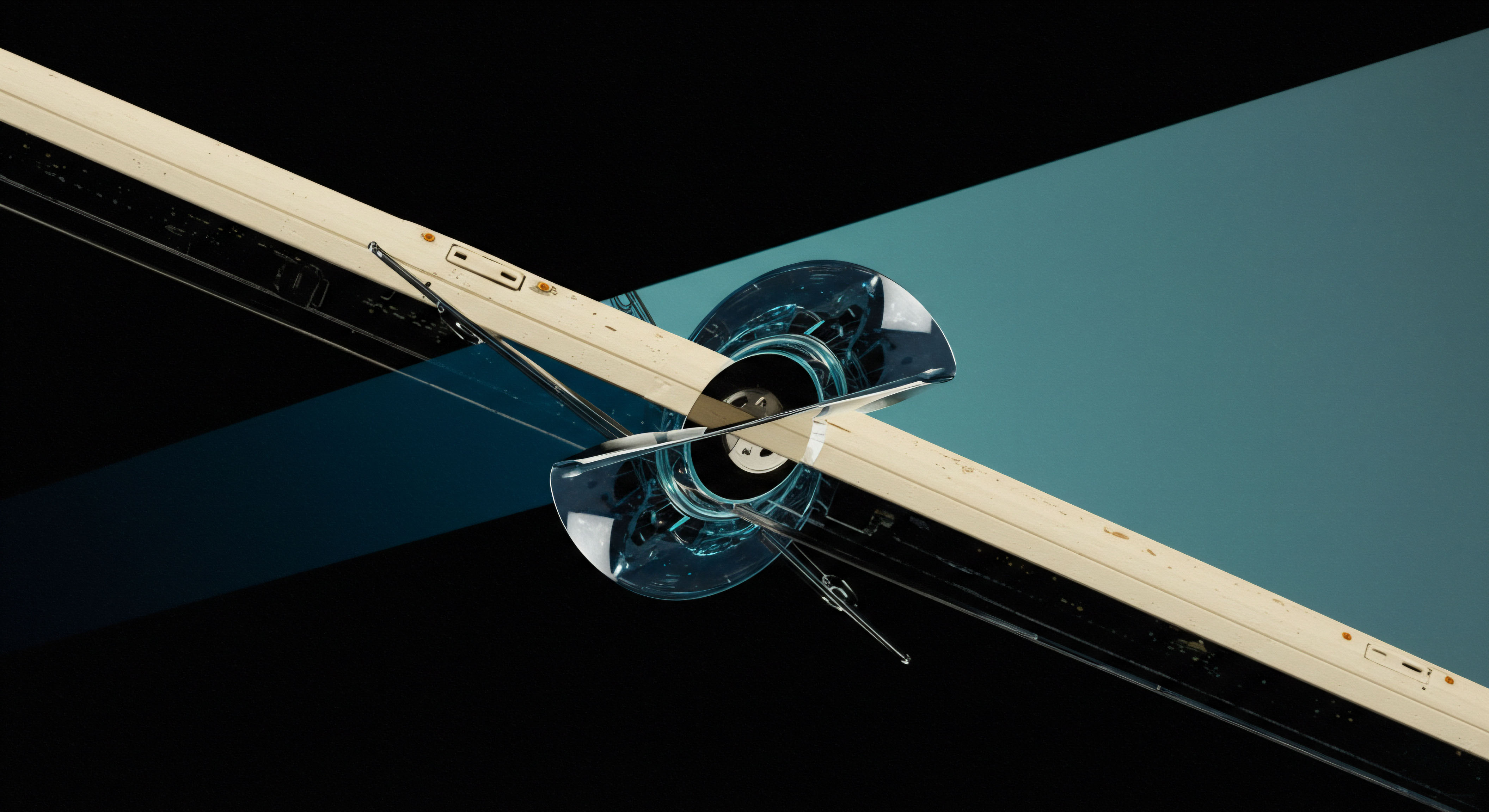

Within the structured environment of a Request for Proposal (RFP) platform, the measurement of this quality transforms from a subjective assessment into a data-driven discipline. The platform itself becomes an observatory, a controlled environment where interactions, performance, and collaborative potential can be quantified and analyzed with precision.

The core purpose of measuring this quality is to build a predictive model of supplier performance. It is about architecting a system that provides a high-fidelity view of how a supplier will behave under both optimal and stressed conditions. This requires a move beyond simple, lagging indicators like defect rates. A robust measurement framework integrates multiple data layers, from the transactional efficiency captured in order accuracy to the strategic alignment revealed in collaborative indices.

The RFP platform acts as the central nervous system for this data collection, channeling diverse inputs into a coherent, actionable intelligence layer. This intelligence informs not just individual procurement decisions but the strategic composition of the entire supply base.

The objective is to construct a holistic, data-rich model of the supplier ecosystem, where relationship quality is a quantifiable asset.

The Foundational Pillars of Relationship Quality

Supplier relationship quality rests on a foundation of distinct, measurable pillars. Each pillar represents a critical dimension of the partnership, and a failure in one can compromise the integrity of the whole structure. Understanding these pillars is the first step in designing a meaningful measurement framework within an RFP platform.

- Performance Integrity ▴ This is the most tangible pillar, representing the supplier’s capacity to deliver on its core promises. It encompasses the quantitative aspects of the relationship, such as the quality of goods or services, the reliability of delivery schedules, and adherence to contractual cost structures. Performance integrity forms the bedrock of trust; without it, no strategic partnership can be sustained.

- Operational Alignment ▴ This pillar measures the seamlessness of the interface between the two organizations. It looks at the ease of communication, the accuracy of order fulfillment, and the responsiveness of the supplier to inquiries and issues. High operational alignment reduces transactional friction, freeing up resources to focus on strategic initiatives rather than administrative overhead.

- Strategic Congruence ▴ This dimension assesses the degree to which a supplier is a true partner in value creation. It includes their contribution to innovation, their willingness to collaborate on process improvements, and their proactivity in identifying and mitigating risks. Strategic congruence is the hallmark of a mature, high-value relationship that transcends a simple transactional dynamic.

- Risk Posture ▴ This pillar provides a forward-looking view of potential disruptions. It involves evaluating a supplier’s financial stability, their compliance with regulatory and ethical standards, and the transparency of their own supply chain. A favorable risk posture indicates a resilient partner who contributes to the stability of the entire operational ecosystem.

Each of these pillars can be deconstructed into a set of specific, quantifiable metrics. The power of an RFP platform is its ability to systematically capture data against each of these pillars, transforming an abstract concept like “relationship quality” into a structured, empirical dataset ready for analysis.

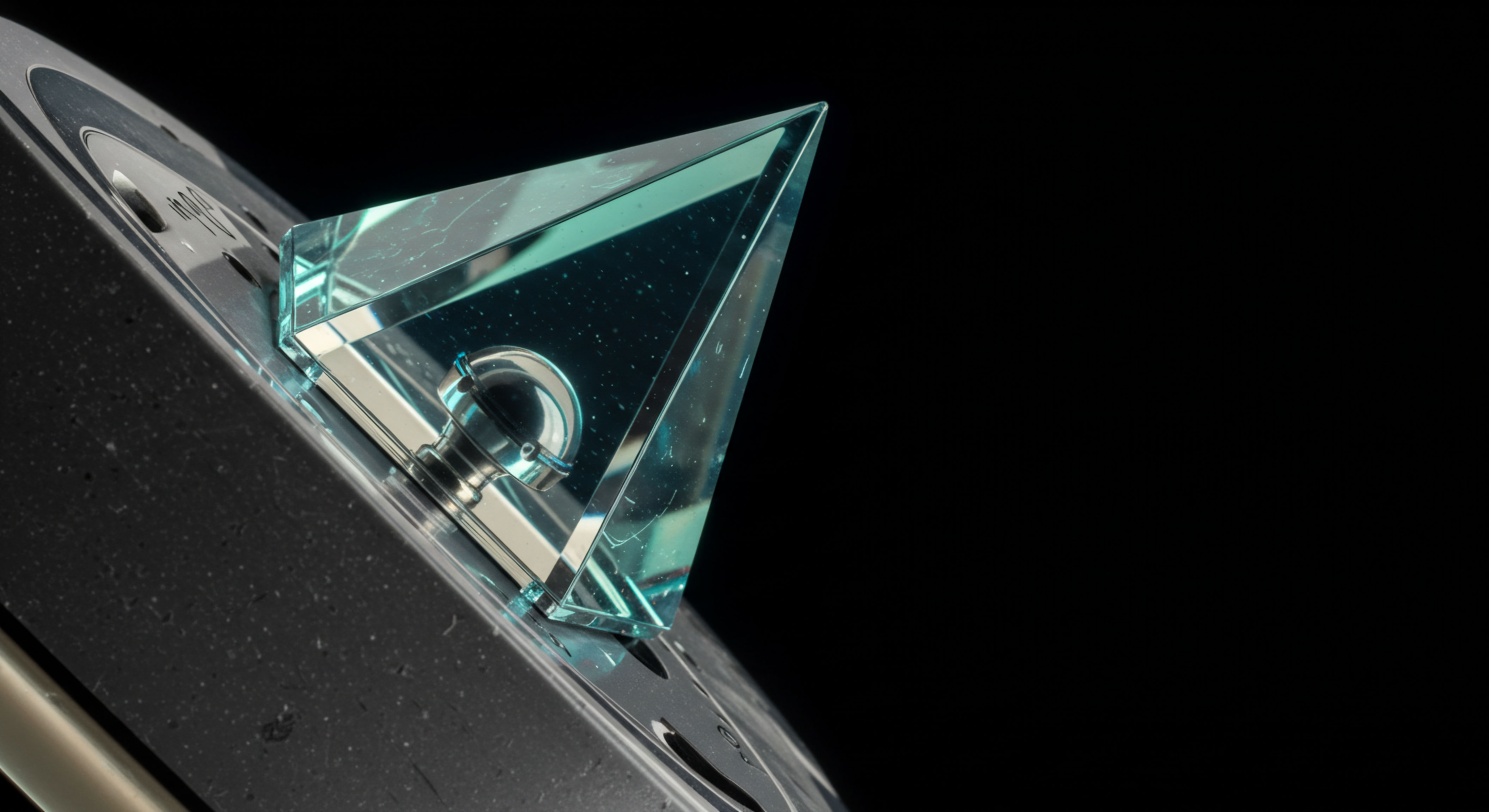

Strategy

Designing the Measurement Architecture

A strategic approach to measuring supplier relationship quality requires a deliberate design of the measurement architecture. This is not about an ad-hoc collection of interesting data points; it is about building a coherent system where each metric serves a specific analytical purpose. The architecture must balance different types of metrics to create a multi-dimensional and dynamic view of supplier relationships. This involves a strategic classification of metrics into distinct categories, each providing a unique layer of insight.

The initial design phase within the RFP platform should focus on defining the objectives of the measurement program. Is the primary goal to drive cost savings, mitigate risk, foster innovation, or improve operational efficiency? The answer to this question will determine the relative weighting and importance of different metric categories.

A well-designed architecture is adaptable, allowing for shifts in strategic priorities over time without requiring a complete overhaul of the measurement framework. The RFP platform should be configured to support this adaptability, allowing administrators to adjust metric sets and scoring models as business needs evolve.

A Taxonomy of Relationship Metrics

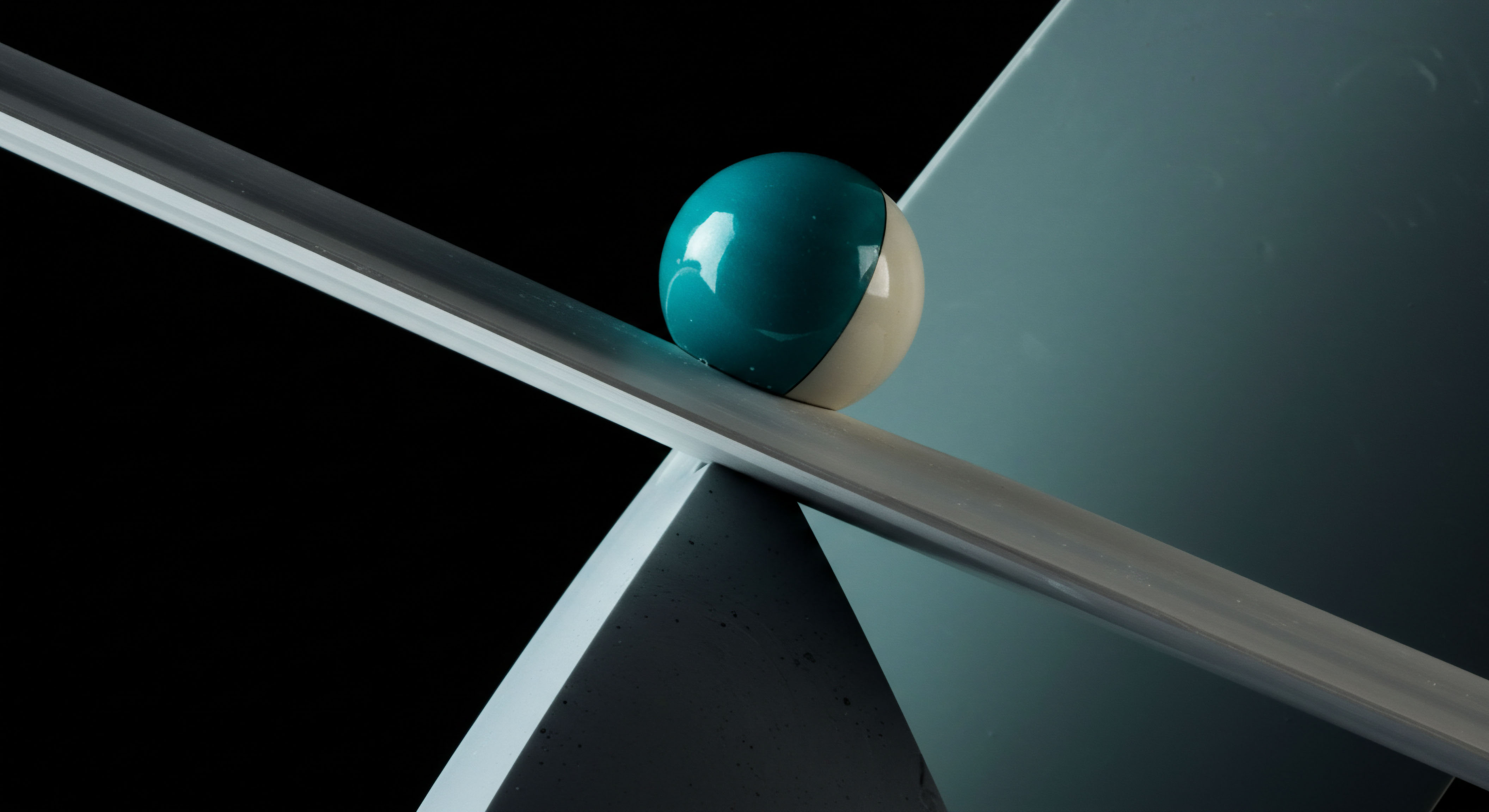

To construct a comprehensive view, metrics can be classified along two key axes ▴ their nature (quantitative vs. qualitative) and their temporal focus (leading vs. lagging). Understanding this taxonomy is fundamental to building a balanced and insightful supplier scorecard.

- Quantitative Metrics ▴ These are the objective, numerical data points that reflect supplier performance. They are easily aggregated and tracked over time. Examples include On-Time Delivery (OTD) rates, defect rates, and cost variance. These metrics provide a hard, factual basis for performance evaluation.

- Qualitative Metrics ▴ These metrics capture the more subjective aspects of the relationship. They are often collected through surveys and assessments completed by internal stakeholders who interact with the supplier. Examples include ratings for communication effectiveness, responsiveness, and collaborative spirit. While subjective, these metrics provide essential context to the quantitative data.

- Lagging Indicators ▴ These metrics measure past performance. They tell you what has already happened. Defect rates and on-time delivery percentages are classic lagging indicators. They are useful for evaluating historical performance but have limited predictive power on their own.

- Leading Indicators ▴ These metrics offer insight into future performance. They are often process-oriented and can signal potential issues before they impact outcomes. A supplier’s rate of participation in joint planning sessions or their investment in new technology could be considered leading indicators. They are more difficult to measure but are invaluable for proactive relationship management.

A balanced scorecard integrates all four types of metrics, creating a system that evaluates past performance while generating predictive insights.

The following table illustrates how different metrics fit within this classification framework, providing a blueprint for a balanced supplier scorecard within an RFP platform.

| Metric Category | Metric Example | Nature | Temporal Focus | Strategic Purpose |

|---|---|---|---|---|

| Delivery Performance | On-Time In-Full (OTIF) Rate | Quantitative | Lagging | Measures reliability and operational excellence. |

| Quality Management | Defect Rate (PPM) | Quantitative | Lagging | Assesses adherence to quality standards. |

| Cost Management | Cost Savings Achieved | Quantitative | Lagging | Evaluates financial contribution and negotiation effectiveness. |

| Collaboration & Innovation | Supplier Innovation Contribution Index | Qualitative/Quantitative | Leading | Gauges potential for future value creation. |

| Responsiveness | Corrective Action Request (CAR) Closure Rate | Quantitative | Leading | Indicates problem-solving capability and process agility. |

| Relationship Health | Supplier Relationship Index (SRI) Score | Qualitative | Leading | Assesses the overall health and stability of the partnership. |

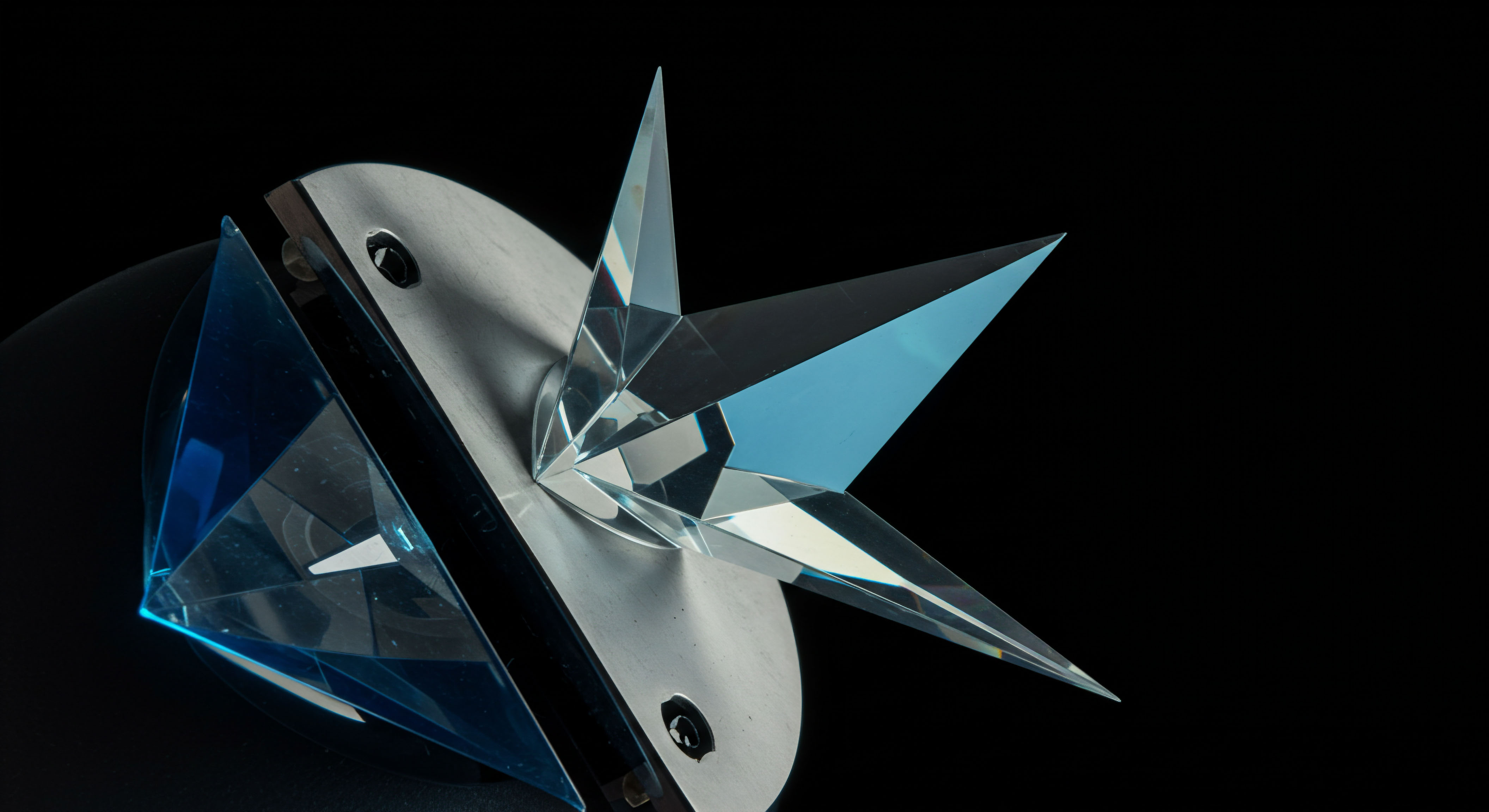

Execution

The Operational Playbook for Metric Implementation

The execution of a supplier relationship quality measurement system within an RFP platform is a multi-stage process that moves from data aggregation to analytical modeling. It requires a disciplined, procedural approach to ensure the resulting intelligence is both accurate and actionable. This playbook outlines the critical steps for operationalizing the measurement framework.

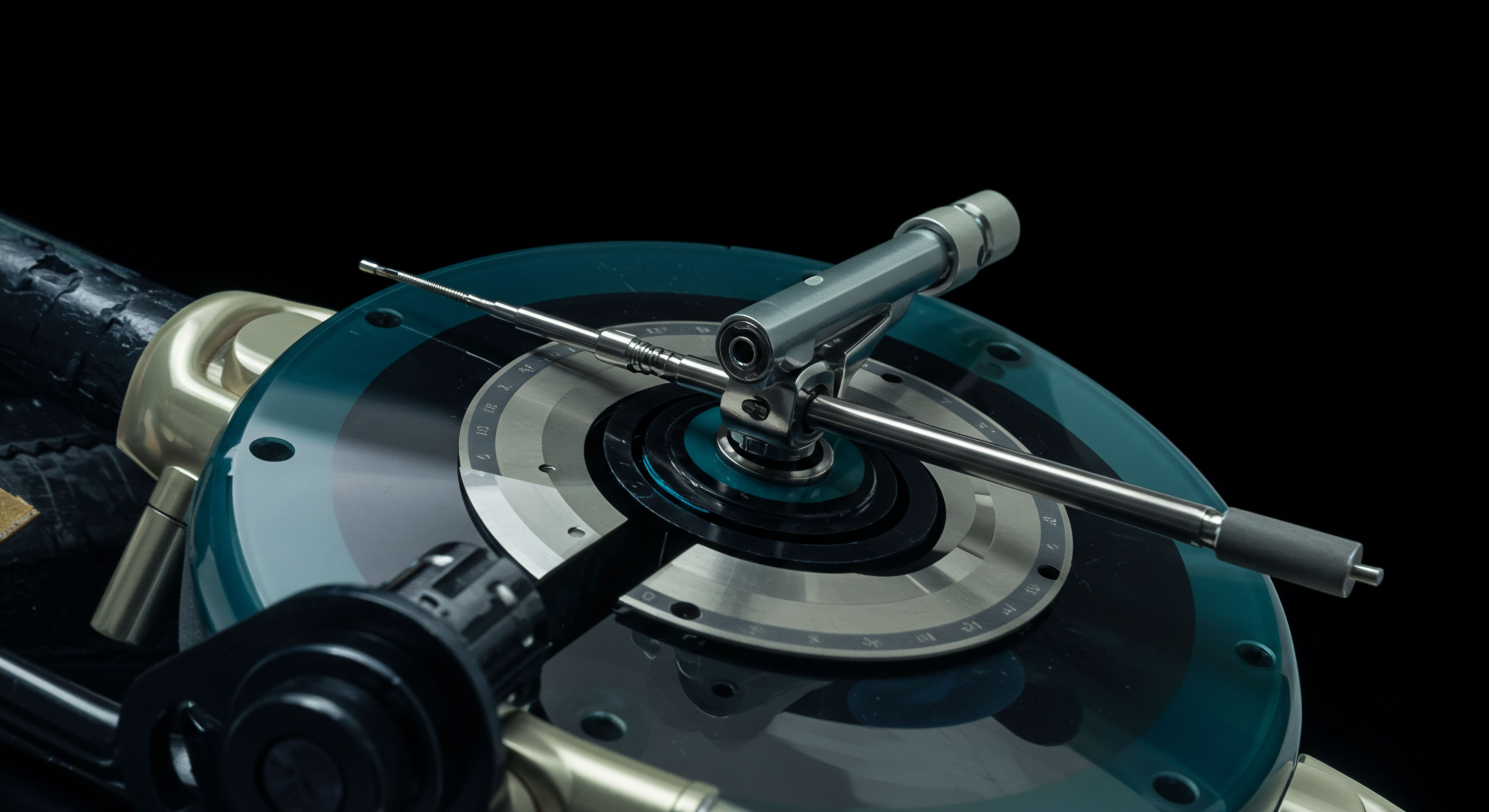

- Define The Data Schema ▴ The first step is to precisely define every metric that will be tracked. For each metric, specify the data source (e.g. ERP system, survey module in the RFP platform, manual input), the unit of measure, the calculation formula, and the desired reporting frequency. This foundational work ensures data consistency and integrity across the entire system.

- Configure The Platform For Data Capture ▴ The RFP platform must be configured to act as the central repository for all relationship quality data. This may involve setting up integrations with other enterprise systems, such as an ERP for transactional data or a QMS for quality data. For qualitative data, it involves designing and deploying standardized surveys and assessment forms directly within the platform’s communication modules.

- Establish Scoring And Weighting ▴ Once data is flowing, the next step is to develop a scoring model. This involves converting raw metric data into a normalized score (e.g. on a 1-100 scale). Following normalization, strategic weights are assigned to each metric based on its importance to the organization’s objectives. For instance, for a critical component, the ‘Defect Rate’ metric might carry a higher weight than for a commodity item.

- Automate The Composite Score Calculation ▴ The platform should be programmed to automatically calculate a composite Supplier Relationship Quality (SRQ) score for each supplier. This score is a weighted average of all the individual normalized metric scores. This provides a single, high-level indicator of relationship health that can be tracked over time and used to segment the supplier base.

- Develop Action-Oriented Dashboards ▴ The final step is to visualize the data. Create dashboards within the RFP platform that present the SRQ scores, as well as the underlying metric data, in an intuitive format. These dashboards should enable procurement professionals to quickly identify trends, drill down into performance issues, and compare suppliers. The visualization should be designed to support decision-making, not just to display data.

Quantitative Modeling for a Composite Quality Score

The heart of the execution phase is the quantitative model that synthesizes diverse metrics into a single, coherent Supplier Relationship Quality (SRQ) score. This model provides a systematic and objective basis for evaluating and comparing suppliers. The table below provides a hypothetical example of how this model would function for two different suppliers, illustrating the calculation from raw data to the final composite score.

| Metric | Strategic Weight | Supplier A Raw Data | Supplier A Normalized Score (1-100) | Supplier A Weighted Score | Supplier B Raw Data | Supplier B Normalized Score (1-100) | Supplier B Weighted Score |

|---|---|---|---|---|---|---|---|

| On-Time In-Full (OTIF) | 25% | 98.5% | 98.5 | 24.63 | 95.2% | 95.2 | 23.80 |

| Defect Rate (PPM) | 30% | 500 | 90.0 | 27.00 | 1,200 | 76.0 | 22.80 |

| Lead Time Variance | 15% | +/- 1 day | 95.0 | 14.25 | +/- 3 days | 85.0 | 12.75 |

| Responsiveness Score (Survey) | 15% | 4.8 / 5.0 | 96.0 | 14.40 | 3.9 / 5.0 | 78.0 | 11.70 |

| Innovation Contribution Score | 15% | 8 / 10 | 80.0 | 12.00 | 5 / 10 | 50.0 | 7.50 |

| Total SRQ Score | 100% | 92.28 | 78.55 |

This model demonstrates how the RFP platform can serve as an analytical engine. It transforms a complex array of performance data into a clear, objective, and strategically relevant output. The SRQ score becomes a key input for supplier segmentation, risk assessment, and the development of targeted relationship management strategies.

Systematic quantitative modeling elevates supplier management from a reactive function to a strategic, data-driven capability.

System Integration and Technological Architecture

The successful execution of a supplier quality measurement program hinges on a robust technological architecture. The RFP platform must function as the central hub in a connected ecosystem of enterprise applications. This requires a carefully planned approach to system integration, ensuring a seamless and automated flow of data. The primary integration points typically include Enterprise Resource Planning (ERP) systems, Quality Management Systems (QMS), and sometimes even financial analysis platforms for assessing supplier fiscal health.

API-driven integration is the modern standard for this architecture. The RFP platform should expose a set of well-documented APIs (Application Programming Interfaces) that allow other systems to both push and pull data. For example, an ERP system could use an API to automatically push purchase order and delivery data into the platform, which would then update the OTIF and order accuracy metrics. Conversely, the RFP platform’s calculated SRQ scores could be pulled via an API into a central business intelligence dashboard.

This two-way data synchronization creates a single source of truth and eliminates the need for manual data entry, which is both inefficient and prone to error. The architecture must be secure, scalable, and resilient, ensuring that the data feeding the quality models is always timely and accurate.

References

- Bridges, Mark. “Top 10 Supplier Relationship Management (SRM) KPIs.” Medium, 15 Mar. 2024.

- “8 Supplier Performance Management KPIs for 2025.” Procurement Tactics, 25 July 2025.

- “10 Supplier Quality Metrics For Procurement.” ClicData, 4 Mar. 2024.

- “Key Non-Financial KPIs for Managing Supplier Relationships.” Growing Your Numbers.

- “14 Key Metrics for Assessing Supplier Performance.” Veridion, 12 Jan. 2025.

- Handfield, R. B. et al. “A Causal Model of Supplier-Buyer Relationship and Performance Outcomes in a Service Environment.” International Journal of Physical Distribution & Logistics Management, vol. 45, no. 1/2, 2015, pp. 144-165.

- Carr, A. S. and J. N. Pearson. “Strategically managed buyer ▴ supplier relationships and performance outcomes.” Journal of Operations Management, vol. 17, no. 5, 1999, pp. 497-519.

- Forker, L. B. and R. M. Monczka. “Supplier-base management ▴ a multi-objective mathematical programming approach.” International Journal of Production Economics, vol. 56-57, 1998, pp. 207-219.

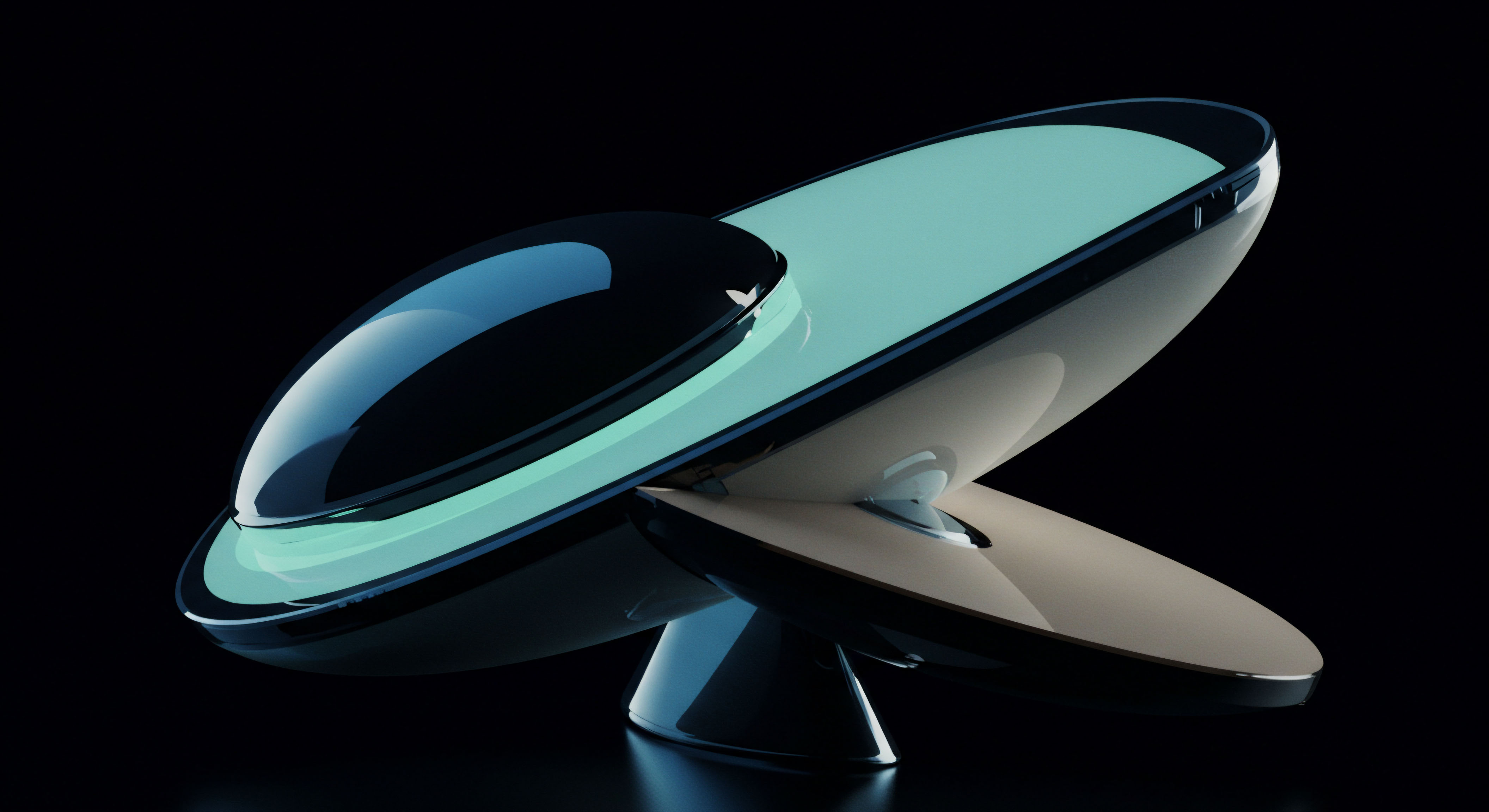

Reflection

From Measurement to Systemic Advantage

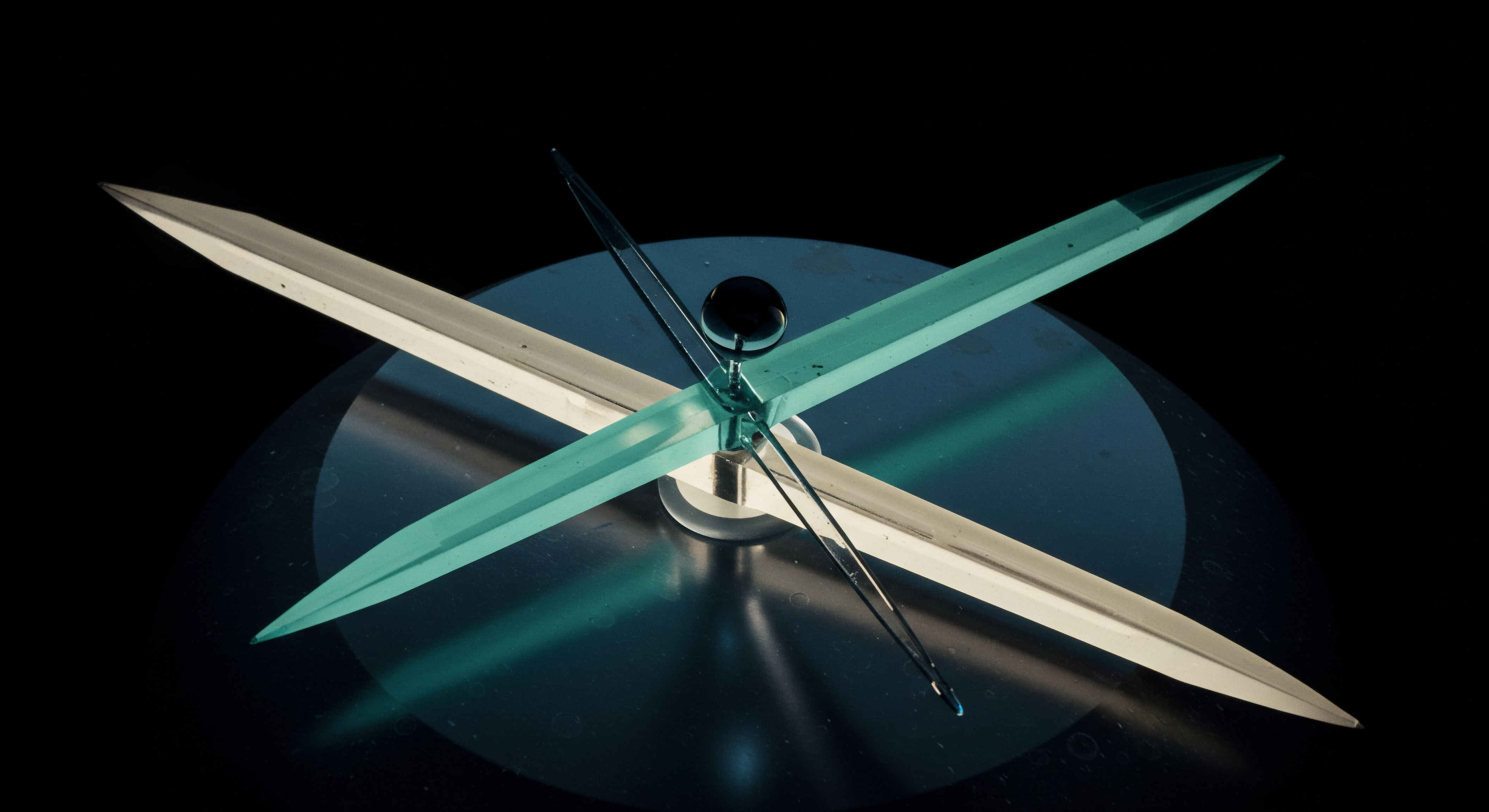

The implementation of a data-driven framework for measuring supplier relationship quality is not an end in itself. Its ultimate purpose is the creation of a durable, systemic advantage. The intelligence generated by this system provides the foundation for a more strategic and resilient approach to supply chain architecture.

It allows an organization to move beyond reactive problem-solving and begin proactively shaping its supplier ecosystem to align with long-term strategic goals. The RFP platform, in this context, evolves from a simple transactional tool into a strategic command center.

Consider how the continuous stream of quality data informs the very structure of future RFPs. An understanding of which suppliers excel in innovation allows for the design of more collaborative, co-development-focused proposal requests. Knowledge of which partners demonstrate the highest operational alignment can lead to the creation of streamlined, automated procurement channels for certain categories.

The data illuminates the path forward, enabling a level of strategic precision that is unattainable through intuition alone. The question then becomes not just “who is our best supplier today?” but “what is the optimal composition of our supplier network for tomorrow?” This shift in perspective is the true return on the investment in a measurement system.

Glossary

Supplier Relationship Quality

Measurement Framework

Supplier Performance

Rfp Platform

Supplier Relationship

Relationship Quality

Measuring Supplier Relationship Quality

Supplier Relationships

Platform Should

These Metrics