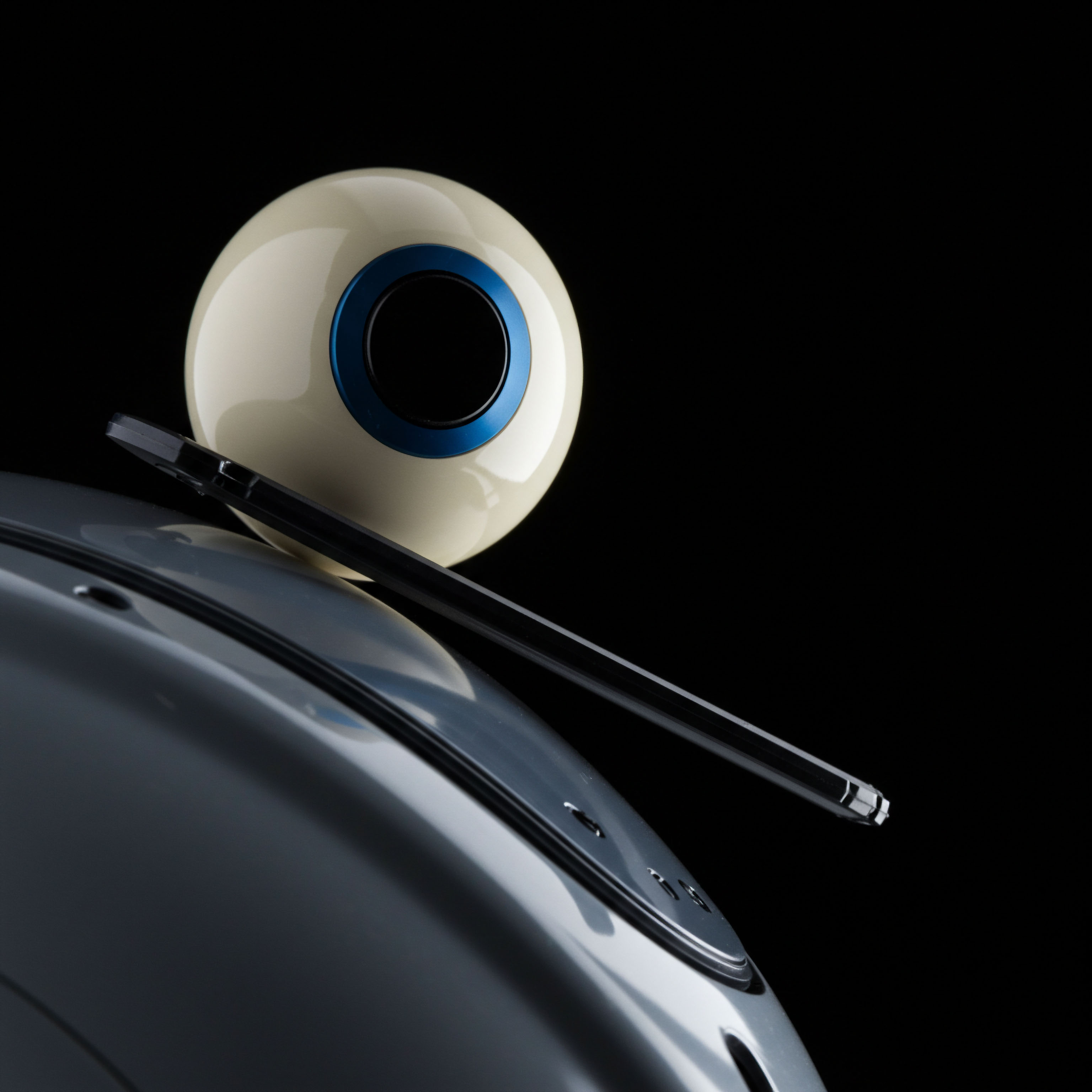

Concept

An inquiry into the architectural requirements of a real-time leakage detection system (LDS) begins with a foundational understanding of its purpose. A modern LDS is an integrated nerve center for asset integrity. Its function is to translate a constant stream of physical data into actionable intelligence, preserving operational continuity, safeguarding environmental standards, and protecting capital-intensive infrastructure. The system’s architecture is the blueprint for a high-fidelity monitoring apparatus designed to identify, quantify, and locate anomalous material losses with precision and speed.

At its core, the architecture answers a critical operational question ▴ how can we achieve a persistent, verifiable, and dynamic understanding of a containment system’s state? This question moves the objective from simple anomaly flagging to a comprehensive surveillance capability. The architectural design must therefore be predicated on the seamless fusion of sensor physics, data telemetry, computational modeling, and human-factor engineering.

It is a system built to provide certainty in environments where uncertainty carries significant financial and safety implications. The primary goal is to minimize the time between a loss of containment and a confirmed detection, thereby reducing the potential impact of an event.

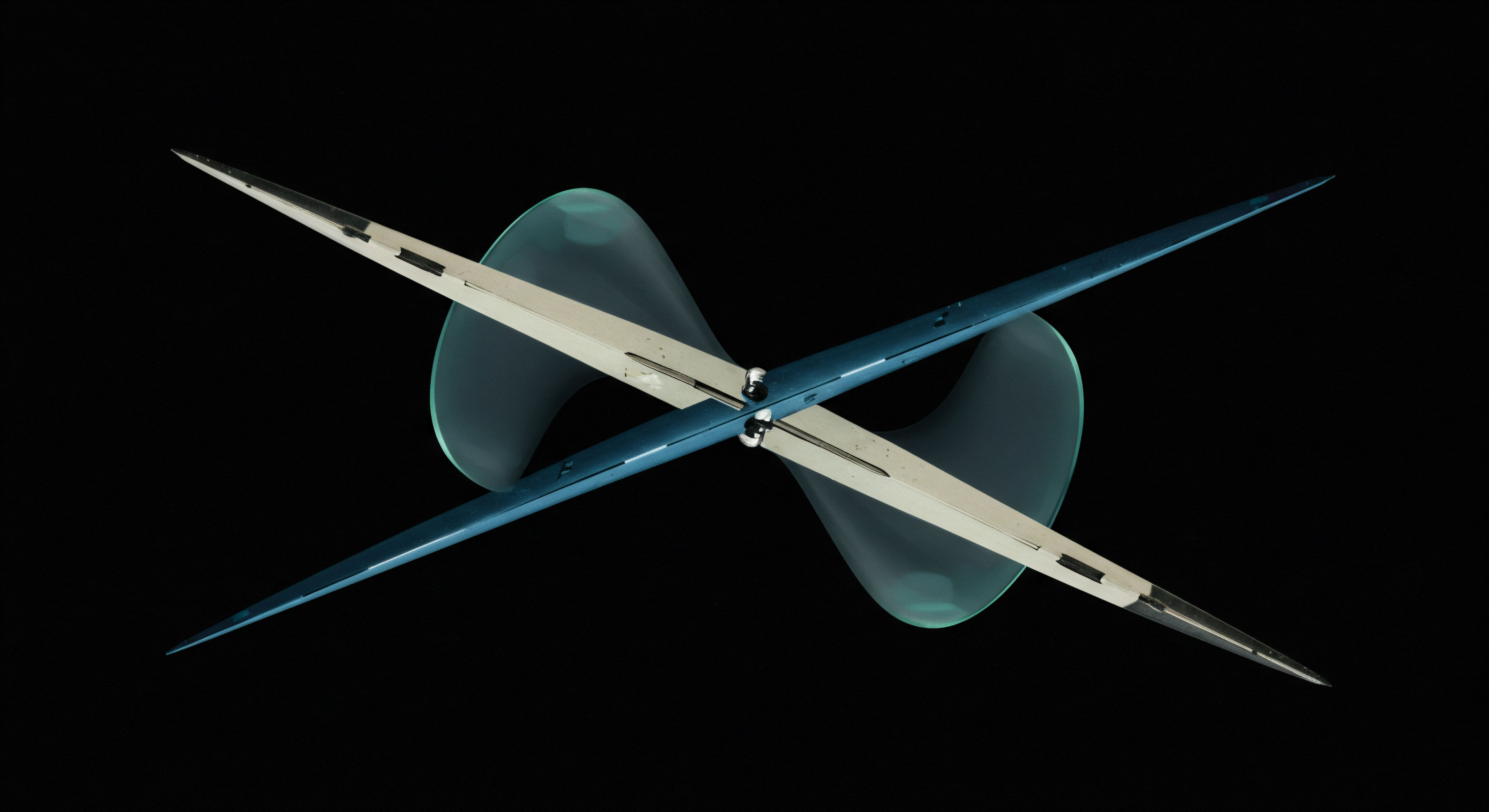

The design philosophy of a robust LDS architecture is rooted in defense-in-depth. This involves layering multiple, often complementary, detection methodologies to create a system that is more sensitive and reliable than any single component. For instance, a Real-Time Transient Model (RTTM) might be complemented by statistical process control analysis or specialized hardware like fiber-optic sensing cables.

This layered approach acknowledges that no single method is infallible and that different leak scenarios present unique physical signatures. The architecture must therefore be a flexible framework, capable of integrating diverse data streams and analytical techniques into a single, coherent operational picture for the controller.

What Defines the System’s Core Mandate?

The core mandate of a leakage detection system is to provide immediate, reliable, and accurate alerts upon a loss of containment. This mandate is driven by regulatory requirements, operational safety protocols, and the economic imperative to prevent product loss and environmental damage. The system must be engineered to overcome the inherent challenges of its operating environment, such as signal noise, transient operational states, and the vast physical scale of the monitored asset, like a pipeline stretching for hundreds of kilometers. Consequently, the architecture must prioritize sensitivity to detect small leaks, reliability to avoid false alarms, and accuracy in locating the source.

A system’s value is directly tied to the trust operators place in it. An architecture that generates frequent false alarms will lead to operator fatigue and a desensitization to genuine alerts, undermining its entire purpose. Reliability is therefore an architectural pillar, achieved through sophisticated algorithms that can distinguish between a genuine leak signature and normal operational fluctuations. This involves advanced modeling and, increasingly, machine learning techniques that learn the unique hydraulic or acoustic profile of the pipeline under normal conditions.

Data as the Foundation of Detection

Data is the lifeblood of any real-time leakage detection system. The architecture is fundamentally a design for data acquisition, transmission, processing, and interpretation. The quality and granularity of the input data directly constrain the system’s detection capabilities. Key data streams typically include:

- Pressure ▴ High-resolution pressure readings from multiple points along a pipeline are critical for detecting the negative pressure wave that propagates from a leak point.

- Flow Rate ▴ Precise measurement of flow in and out of a defined pipeline segment allows for mass balance calculations, a foundational method for leak detection.

- Temperature ▴ Fluid temperature affects its viscosity and density, which are important parameters for hydraulic models. Temperature can also be a direct indicator of a leak in some applications.

- Acoustic Signals ▴ Specialized sensors can listen for the specific acoustic signature generated by fluid escaping a pressurized pipe, offering a highly sensitive detection method.

The system architecture must specify the required resolution, sampling rate, and accuracy of these sensors. It must also define the communication infrastructure (e.g. SCADA telemetry networks, fiber-optic cables) responsible for transmitting this data to a central processing unit in a timely and reliable manner. The robustness of this data acquisition network is as critical as the analytical software itself; corrupted or delayed data renders even the most advanced algorithms ineffective.

Strategy

The strategic design of a real-time leakage detection system involves a series of critical decisions that balance performance, cost, and operational constraints. The selection of a detection methodology, or more commonly a combination of methodologies, is the central strategic choice. This choice is governed by the nature of the fluid, the type and scale of the infrastructure, the regulatory environment, and the specific risks the operator seeks to mitigate. A strategy for a subsea oil pipeline will differ significantly from one for a municipal water distribution network or a data center’s liquid cooling circuit.

A well-defined strategy transforms a leakage detection system from a reactive alarm tool into a proactive asset management framework.

Selecting the Appropriate Detection Paradigm

The primary strategic decision is the selection of the core detection paradigm. These paradigms fall into two broad categories ▴ internally based systems that rely on internal process variables (pressure, flow) and externally based systems that use dedicated, localized sensors to detect escaping fluid. The optimal strategy often involves a hybrid approach, leveraging the strengths of multiple methods to enhance sensitivity and reliability.

Internally Based Systems (Software-Based)

These systems utilize existing Supervisory Control and Data Acquisition (SCADA) infrastructure to gather data from pressure, flow, and temperature sensors. Their primary advantage is the ability to monitor the entire length of a pipeline from a central location without requiring additional field hardware along the asset’s right-of-way.

- Mass Balance ▴ This is the most straightforward method, calculating the difference between the fluid volume entering a pipeline segment and the volume exiting it over a specific time. While simple in concept, its effectiveness depends on highly accurate and synchronized flow meters.

- Real-Time Transient Modeling (RTTM) ▴ This is a more sophisticated, physics-based approach. The system creates a detailed mathematical model of the pipeline’s hydraulic behavior. It compares real-time sensor readings to the model’s predictions. A significant deviation between the measured and predicted values indicates an anomaly, such as a leak. E-RTTM, or Extended RTTM, further enhances this by integrating statistical methods to reduce false alarms during transient conditions.

- Statistical Process Control (SPC) ▴ These methods analyze the patterns and statistical properties of pressure and flow data. They do not rely on a physical model but instead learn the normal “statistical signature” of the pipeline. A deviation from this learned baseline can indicate a leak. This approach is particularly effective for identifying small, slow-developing leaks that might be missed by other methods.

Externally Based Systems (Hardware-Based)

These systems employ sensors installed along the pipeline to directly detect the physical presence of the leaking substance or a related phenomenon. They offer high sensitivity and precise location accuracy but typically involve higher installation and maintenance costs.

The table below compares common externally based detection strategies:

| Detection Strategy | Sensing Mechanism | Primary Advantage | Key Limitation |

|---|---|---|---|

| Acoustic Sensing | Microphones or hydrophones detect the ultrasonic noise generated by escaping, pressurized fluid. | High sensitivity to very small leaks and rapid detection speed. | Can be susceptible to background noise from pumps or valves. |

| Fiber-Optic Sensing | A fiber-optic cable buried along the pipeline detects changes in temperature (Distributed Temperature Sensing) or strain/vibration (Distributed Acoustic Sensing) caused by a leak. | Provides continuous monitoring along the entire length of the cable with precise location accuracy. | Higher initial installation cost and vulnerability to cable damage. |

| Vapor Sensing | Chemical sensors detect airborne particles of the leaking substance. | Very specific to the substance being monitored, reducing false alarms from other sources. | Requires the leak to be large enough to create a detectable vapor cloud, limiting its use for sub-surface leaks. |

| Digital Sensing Cables | Specially designed cables trigger an alarm when they come into physical contact with the leaking fluid. | Provides definitive, unambiguous detection with good location accuracy. | Requires close proximity to the potential leak point, often used in contained environments like data centers or valve stations. |

How Should the Architecture Address Scalability and Future Needs?

A forward-looking strategy considers the entire lifecycle of the asset. The LDS architecture must be scalable to accommodate future expansions of the network and adaptable to incorporate new technologies. A modular design is highly advantageous, allowing for the addition of new sensor types or the upgrading of analytical software without requiring a complete system overhaul.

Furthermore, the strategy should anticipate the increasing role of artificial intelligence and machine learning. Architectures that facilitate cloud integration and advanced data analytics will be better positioned to leverage AI for predictive diagnostics, identifying pre-leak conditions before a failure occurs.

Execution

The execution phase translates architectural design and strategic choices into a functioning, reliable system. This is where theoretical models meet operational reality. The process demands meticulous attention to detail in system integration, quantitative modeling, and procedural planning. A successful execution results in an LDS that is not only technically proficient but also seamlessly integrated into the operational workflow of the control room, empowering operators to respond to events with speed and confidence.

The Operational Playbook

Deploying a real-time leakage detection system is a multi-stage project that requires a clear, actionable plan. This playbook outlines the critical steps from conception to continuous operation.

- System Requirements Definition ▴ This initial phase involves a thorough assessment of the asset to be monitored. Key activities include defining the minimum detectable leak size, the required detection time, and the acceptable false alarm rate. This stage must also consider all relevant regulatory mandates, such as those from API, CSA, or PHMSA.

- Technology and Vendor Selection ▴ Based on the requirements, a selection process is undertaken to choose the appropriate blend of detection technologies (e.g. RTTM, acoustic sensing). This involves evaluating potential vendors based on their system’s proven performance, technical support, and ability to integrate with existing SCADA and IT infrastructure.

- Sensor and Hardware Installation ▴ This step involves the physical installation of all required hardware. For software-based systems, this may involve upgrading existing pressure and flow transmitters to meet accuracy and resolution requirements. For external systems, it includes the deployment of acoustic sensors or the trenching and installation of fiber-optic cables.

- System Integration and Configuration ▴ The LDS software is installed and integrated with the SCADA system. This is a critical step where data communication pathways are established and tested. The analytical models (e.g. RTTM, statistical models) are configured with the specific physical parameters of the pipeline, such as diameter, length, material properties, and fluid characteristics.

- System Tuning and Baseline Generation ▴ The system is run in a learning mode to collect data under a wide range of normal operating conditions (e.g. startups, shutdowns, changes in flow rate). This data is used to fine-tune the models and establish a robust operational baseline. This tuning process is critical to maximizing sensitivity while minimizing nuisance alarms.

- Acceptance Testing and Operator Training ▴ The system undergoes a rigorous testing phase, which should include both simulated and, where feasible, live product withdrawal tests to validate its performance against the defined requirements. Concurrently, control room operators receive comprehensive training on the system’s interface, alarm interpretation, and response protocols.

- Continuous Performance Monitoring ▴ An LDS is not a “set and forget” system. Its performance must be continuously monitored. This includes regular reviews of alarm logs, periodic re-tuning of the models to account for changes in pipeline conditions, and ongoing operator training and drills.

Quantitative Modeling and Data Analysis

The core of a software-based LDS is its ability to quantitatively analyze real-time data. The system continuously processes incoming data streams to identify statistical signatures that indicate a leak. For an RTTM-based system, the engine computes a set of “residuals” ▴ the differences between the values measured by sensors and the values predicted by the hydraulic model.

Under normal conditions, these residual values fluctuate around zero, but a leak creates a distinct and persistent deviation.

The following table illustrates a simplified snapshot of data processed by an E-RTTM system before and during a simulated leak event on a crude oil pipeline. The leak begins at timestamp 14:32:10.

| Timestamp | Inlet Flow (m³/hr) | Outlet Flow (m³/hr) | Inlet Pressure (bar) | Model-Predicted Outlet Pressure (bar) | Pressure Residual (bar) | Leak Alarm State |

|---|---|---|---|---|---|---|

| 14:32:00 | 1205.4 | 1205.1 | 75.21 | 42.66 | -0.01 | Normal |

| 14:32:05 | 1205.6 | 1205.3 | 75.22 | 42.68 | 0.00 | Normal |

| 14:32:10 | 1205.5 | 1198.2 | 75.15 | 42.67 | -0.25 | Potential Leak |

| 14:32:15 | 1205.7 | 1190.5 | 74.98 | 42.69 | -0.88 | Confirmed Leak |

| 14:32:20 | 1205.8 | 1182.1 | 74.75 | 42.70 | -1.54 | Confirmed Leak |

In this example, the system detects a discrepancy in the mass balance (Inlet vs. Outlet Flow) and a growing negative residual in the outlet pressure. The leak signature analysis module recognizes this combined pattern as a high-probability leak event, escalating the alarm state from “Potential” to “Confirmed” and providing the operator with a clear and immediate notification.

Predictive Scenario Analysis

Consider a 150-kilometer natural gas transmission pipeline operating at 80 bar. The pipeline is equipped with an E-RTTM system and fiber-optic Distributed Acoustic Sensing (DAS). At 03:45 AM, a third-party contractor performing unauthorized excavation work strikes the pipeline, creating a pinhole leak equivalent to 1% of the nominal flow rate. The event unfolds within the LDS as follows:

Instantly, the escaping high-pressure gas generates a unique acoustic signature. The DAS system, with its continuous fiber-optic sensor running parallel to the pipe, detects this acoustic event. Within seconds, the system’s central processor receives the signal. The processor’s pattern recognition algorithm compares the signature to its library of known events and immediately classifies it as a gas leak.

It pinpoints the location to within 5 meters, at kilometer post 87.45. An alarm flashes on the SCADA HMI in the central control room, displaying “HIGH-PROBABILITY LEAK DETECTED” with the precise location coordinates.

Simultaneously, the E-RTTM system, which polls pressure and flow sensors every five seconds, begins to register anomalies. The flow meter downstream of the event shows a slight but persistent drop relative to the upstream meter. The pressure sensors near the leak location record a subtle but accelerating decay that deviates from the hydraulic model’s predictions. At 03:45:15, just seconds after the DAS alarm, the E-RTTM’s statistical analysis engine flags these deviations.

The residuals for flow balance and pressure exceed their predefined thresholds. The system correlates its findings with the DAS alarm, confirming the event with two independent methodologies. This confirmation automatically elevates the alarm’s severity.

The control room operator, awakened by the audible alarm, sees the confirmed leak on their main display. The system has already plotted the location on a map and provided the calculated leak rate from the RTTM model. Following protocol, the operator initiates the emergency shutdown procedure. Remotely, they begin closing the mainline block valves upstream and downstream of the leak location to isolate the segment.

The entire sequence, from the physical impact to the initiation of a targeted shutdown, takes less than two minutes. The rapid, accurate, and multi-layered detection prevented a small pinhole leak from escalating into a catastrophic rupture, saving millions in lost product and potential environmental cleanup costs. The system archives all relevant data ▴ acoustic signatures, pressure readings, flow rates, and operator actions ▴ for subsequent regulatory reporting and root cause analysis.

System Integration and Technological Architecture

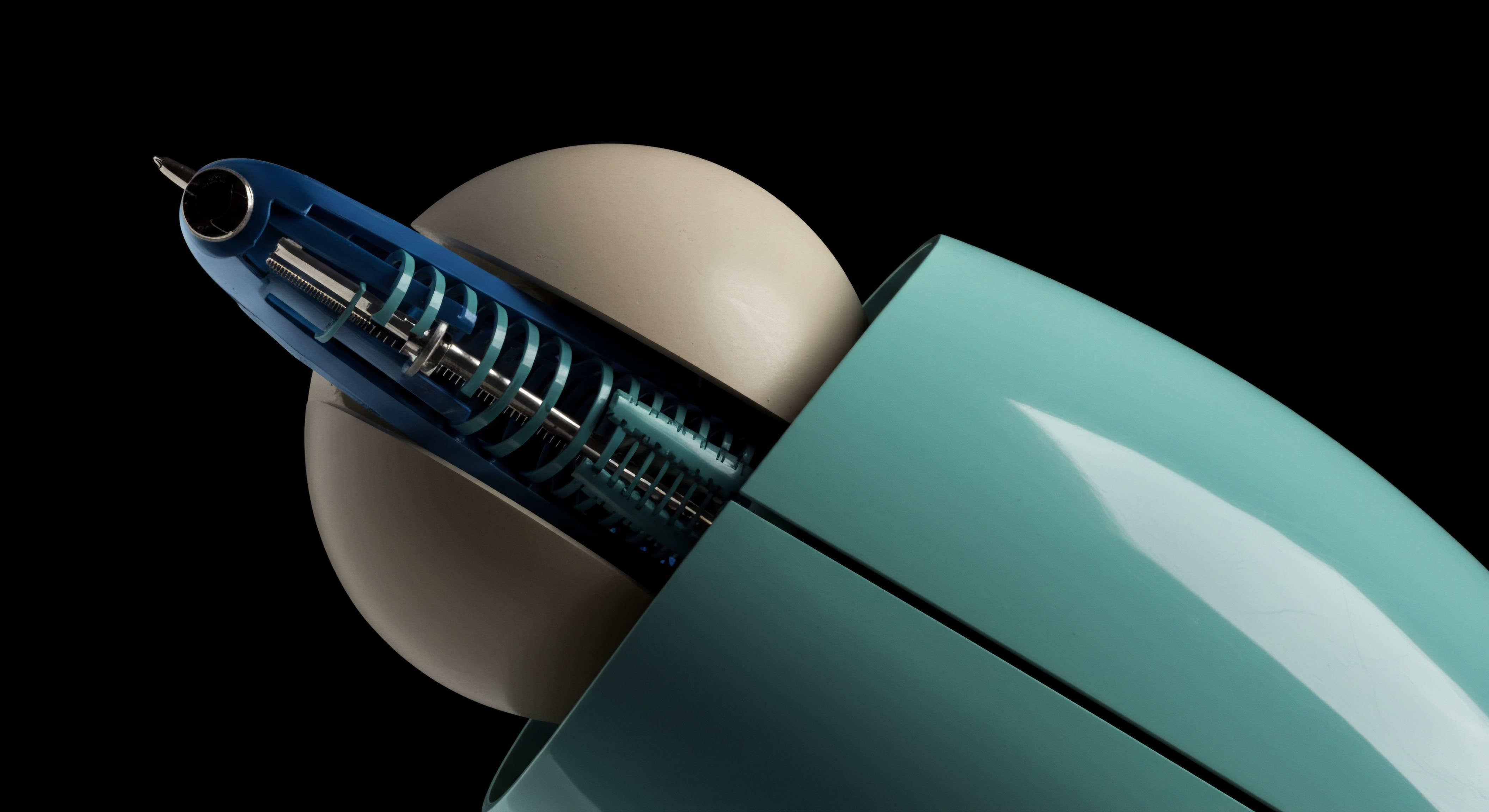

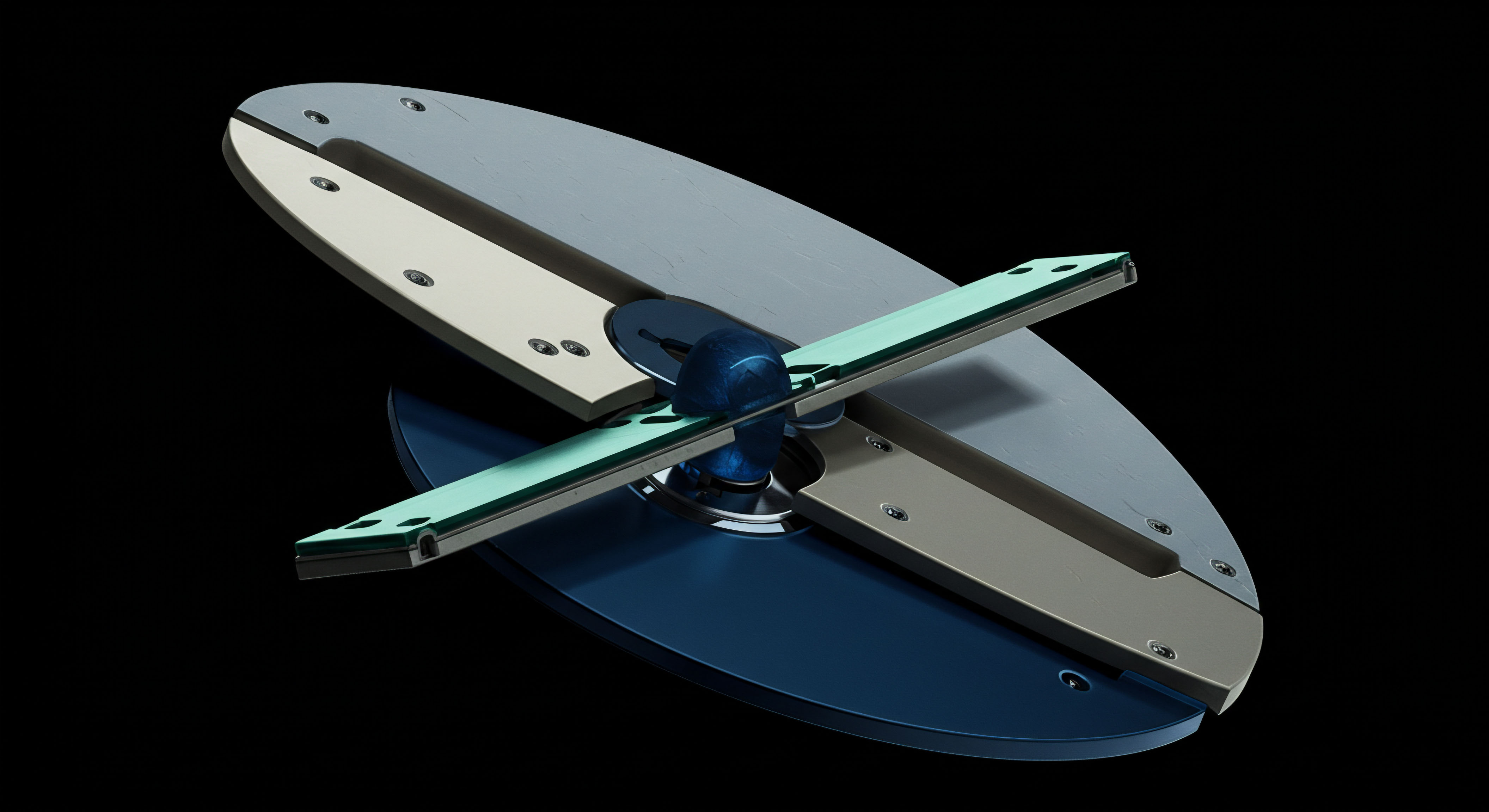

The technological architecture is the complete set of hardware and software components that constitute the LDS. It is a multi-layered structure designed for high availability and real-time performance.

- Layer 1 The Sensor and Field Layer ▴ This is the foundation, comprising all field-level instrumentation. This includes high-precision pressure transmitters, ultrasonic or turbine flow meters, temperature sensors, and any specialized external sensors like acoustic microphones or fiber-optic interrogator units. These devices must be robust enough for their operating environment and calibrated to a high degree of accuracy.

- Layer 2 The Data Acquisition and Telemetry Layer ▴ This layer consists of Remote Terminal Units (RTUs) or Programmable Logic Controllers (PLCs) that poll the sensors and digitize their signals. This data is then transmitted to the central system via a communication network. This network can be based on various technologies, including satellite, microwave, cellular, or a dedicated fiber-optic backbone. Communication protocols like Modbus or DNP3 are commonly used.

- Layer 3 The Processing and Modeling Layer ▴ This is the system’s brain. It typically consists of high-availability servers, which can be located on-premise or in a cloud environment. These servers run the core LDS application software. This software ingests the real-time data, runs the configured analytical models (RTTM, statistical analysis, etc.), and generates alarms. This layer also includes the historical database where all raw and processed data is archived for analysis and reporting.

- Layer 4 The Presentation and HMI Layer ▴ This is the interface to the human operator. It is typically integrated directly into the main SCADA system’s Human-Machine Interface (HMI). This layer provides clear, unambiguous alarm notifications, graphical displays of pipeline profiles, trend charts of key variables, and tools that allow the operator to analyze the data and acknowledge alarms. The design of this layer is critical for enabling rapid and correct decision-making under pressure.

References

- Pipewise Technology. “Building a Leak Detection Architecture Around Your SCADA.” 2025.

- Wang, Shouxi, and John Joseph Carroll. “Leak Detection for Gas and Liquid Pipelines by Online Modeling.” Journal of Pipeline Engineering, 2007.

- Delta Engineering. “Leak detection.” Technical Document.

- “Data Center Leak Detection ▴ A Vital Safety Measure for Modern Infrastructure.” 2024.

- “Hardware architecture of the leakage detection system.” ResearchGate, Technical Drawing.

Reflection

The implementation of a real-time leakage detection system represents a significant commitment to operational excellence. The architectural framework, from the sensor on the pipeline to the alarm on the operator’s screen, is a testament to a proactive stance on safety and asset management. The true value of such a system is realized not just in the leaks it detects, but in the operational discipline it instills. The constant stream of high-fidelity data provides an unprecedented level of insight into the health and behavior of the infrastructure.

As you consider your own operational framework, view this architecture as more than a safety net. It is a source of intelligence. The data it generates can inform predictive maintenance strategies, optimize operational efficiency, and provide a verifiable record of integrity to regulators and stakeholders.

The ultimate goal is to build a system so deeply integrated and so well understood that it transforms the management of the asset from a reactive process to a predictive and controlled science. The architecture you build is the foundation for that transformation.

Glossary

Real-Time Leakage Detection System

Leakage Detection System

False Alarms

Real-Time Leakage Detection

Data Acquisition

System Architecture

Real-Time Leakage

Detection System

Based Systems

Real-Time Transient Modeling

Control Room

Leakage Detection

False Alarm Rate

Distributed Acoustic Sensing