Concept

An institutional approach to a Request for Proposal (RFP) negotiation begins with the construction of an independent reality. This is achieved through a bottom-up cost analysis, a rigorous process of deconstructing a potential supplier’s product or service into its fundamental components of cost. The objective is to build a granular, data-driven model of what a good or service should cost, establishing a profoundly powerful baseline for all subsequent commercial discussions.

This analytical model functions as a system for converting deep operational knowledge into strategic leverage. It moves the procurement function from a reactive posture, dependent on evaluating submitted bids, to a proactive one, where the buying organization defines the financial parameters of a fair agreement before the negotiation even commences.

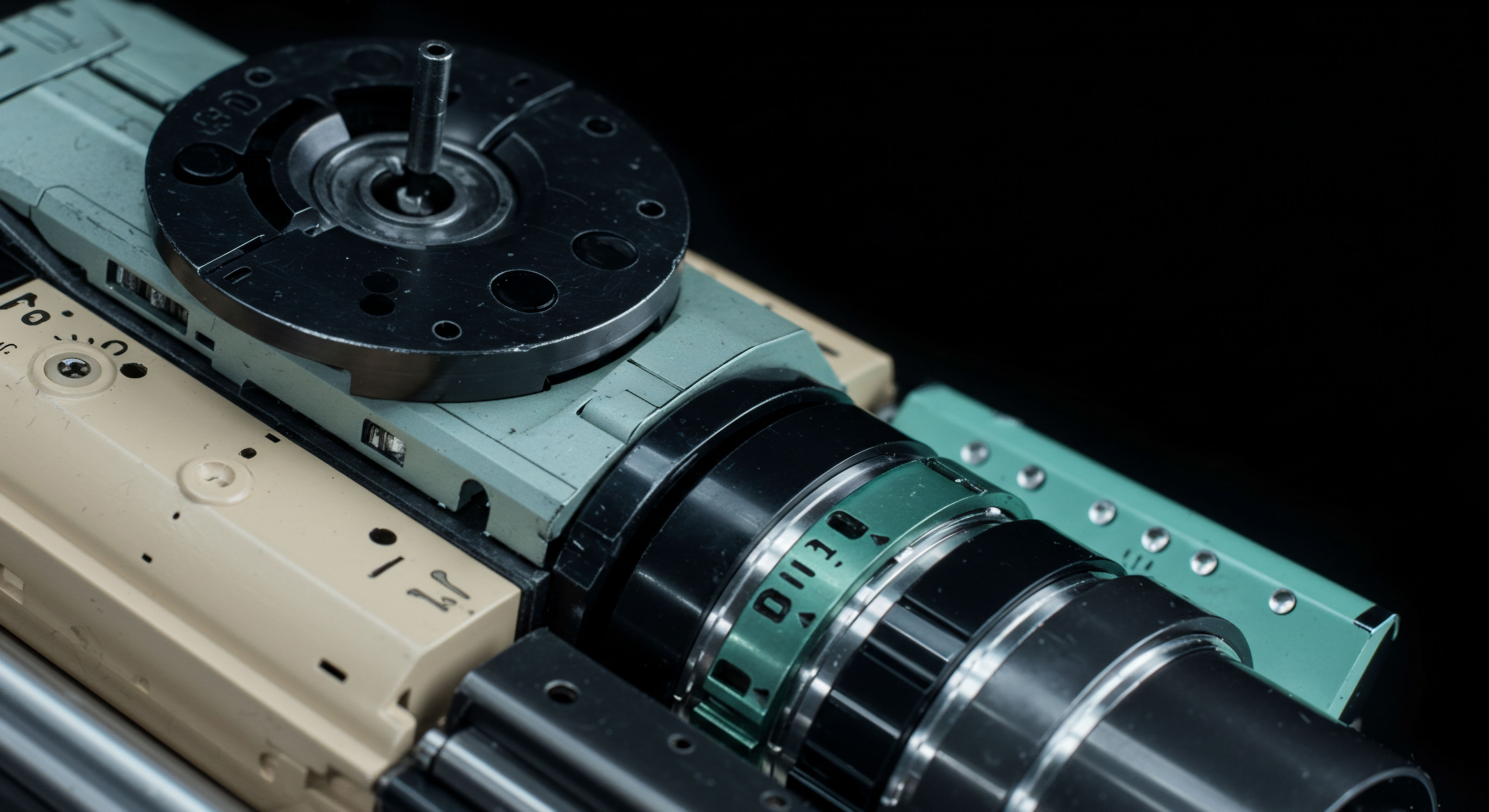

The foundation of this methodology rests on the principle of first-principles thinking applied to procurement. Instead of relying on historical pricing, which may contain legacy inefficiencies, or top-down market comparisons, which can be imprecise, the bottom-up analysis assembles a cost structure from the ground level. This involves quantifying the precise amount and market price of every raw material, calculating the labor hours and standard wages for every assembly and finishing process, and allocating a reasonable proportion of manufacturing and corporate overhead.

A defensible profit margin, aligned with industry and complexity norms, is then added to complete the model. The resulting “should-cost” figure represents a true north, a data-backed position of what a reasonably efficient supplier should be able to achieve.

A bottom-up cost analysis is the architectural process of building a verifiable cost model for a supplier’s offering from its most fundamental components.

This undertaking transforms the nature of the negotiation itself. The dialogue shifts from a contest of wills over a single quoted price to a collaborative, albeit assertive, examination of underlying cost drivers. When a supplier’s proposal deviates significantly from the should-cost model, the conversation can be surgically focused on the specific points of variance.

The analysis provides the vocabulary and the quantitative evidence to ask highly specific, penetrating questions about a supplier’s material sourcing strategies, their labor efficiency, their overhead allocation methods, or their profit expectations. It establishes the buying organization as a highly informed, analytically sophisticated partner, one who negotiates from a position of deep operational intelligence.

Strategy

Forging the Factual Baseline for Negotiation

The strategic utility of a bottom-up cost analysis is its capacity to re-architect the negotiation landscape. It replaces the traditional, often adversarial, dynamic of offer and counter-offer with a framework of objective, verifiable data. By developing a comprehensive should-cost model, the procurement organization establishes an independent, fact-based anchor that grounds the entire negotiation process.

This model serves as the central reference point, enabling the negotiation team to evaluate supplier proposals not against each other, but against a meticulously constructed benchmark of what is reasonable and efficient. This fundamentally alters the power dynamic, positioning the buyer as the authority on cost and value.

Implementing this strategy involves a disciplined, multi-stage process of data aggregation and analysis. The initial phase is dedicated to information gathering, where technical specifications, blueprints, and service level agreements are translated into a detailed Bill of Materials (BOM) or a comprehensive list of required activities. Following this, each element is methodically costed.

This requires deep market intelligence, accessing real-time data on commodity prices, prevailing wage rates for specific labor skills, logistics costs, and industry-standard overhead structures. The synthesis of this data into a coherent model provides a powerful lens through which all supplier bids are viewed, enabling a level of scrutiny that is impossible to achieve with high-level comparisons alone.

The following table illustrates a simplified structure for this analytical model, breaking down the constituent elements of a hypothetical manufactured component.

| Cost Category | Component Element | Unit of Measure | Assumed Quantity | Cost Per Unit ($) | Total Element Cost ($) |

|---|---|---|---|---|---|

| Direct Materials | High-Grade Steel | Kilogram | 2.5 | 3.10 | 7.75 |

| Direct Materials | Polymer Casing | Unit | 1.0 | 1.45 | 1.45 |

| Direct Materials | Fasteners & Fixings | Lot | 1.0 | 0.60 | 0.60 |

| Direct Labor | CNC Machining | Hour | 0.2 | 45.00 | 9.00 |

| Direct Labor | Manual Assembly | Hour | 0.1 | 30.00 | 3.00 |

| Manufacturing Overhead | Machine Depreciation | Per Unit | 1.0 | 2.50 | 2.50 |

| Manufacturing Overhead | Factory Utilities | Per Unit | 1.0 | 1.20 | 1.20 |

| SG&A Overhead | Corporate Allocation | Per Unit | 1.0 | 3.50 | 3.50 |

| Subtotal Cost | 29.00 | ||||

| Profit Margin | Target Profit (15%) | Percentage | 15% | 4.35 | 4.35 |

| Should-Cost Target | 33.35 |

Deconstructing Supplier Proposals with Precision

With a robust should-cost model in place, the strategic focus shifts to its application during the RFP review and negotiation phases. The model becomes a diagnostic tool, used to dissect supplier submissions with surgical precision. When a supplier’s bid is received, it is not treated as a monolithic number. Instead, it is a dataset to be analyzed against the established factual baseline.

The primary activity is variance analysis, where the supplier’s implicit or explicit cost structure is compared to the should-cost model, element by element. This process immediately illuminates the specific areas where the supplier’s pricing diverges from the efficient benchmark.

The strategic purpose of the analysis is to shift negotiation from a debate over price to a data-driven audit of underlying costs and efficiencies.

This granular deconstruction equips the negotiation team with a powerful and targeted line of inquiry. The conversation is elevated from a generic “your price is too high” to a series of specific, data-backed questions that probe the core of the supplier’s operational efficiency and commercial strategy. The analysis provides the foundation to challenge assumptions and uncover the true drivers of a supplier’s price. This strategic questioning fosters a transparent dialogue and compels the supplier to justify their pricing on a factual basis, often revealing opportunities for cost reduction that benefit both parties.

The strategic questions enabled by a bottom-up analysis include:

- Material Economics ▴ Our analysis, based on current market indices, indicates a material cost of $7.75 per unit. Your pricing suggests a figure closer to $9.00. Could you elaborate on the sourcing or specification factors that account for this variance?

- Labor Efficiency ▴ We have modeled the required assembly time at 0.1 hours per unit based on time studies of similar components. What are the specific process steps or labor rates that contribute to the higher labor content in your proposal?

- Overhead Allocation ▴ The allocated manufacturing overhead in your bid appears to be 30% higher than industry benchmarks for a process of this nature. Can you provide insight into the specific cost pools and allocation bases that result in this figure?

- Profit Structure ▴ The implied profit margin in your quote is 25%, whereas the industry standard for components of this complexity and risk profile is closer to 15%. What unique value or risk mitigation justifies this premium?

Execution

The Operational Cadence of Cost Decomposition

The execution of a bottom-up cost analysis is a systematic and disciplined process that translates technical requirements into a financial model. It demands cross-functional collaboration, bringing together engineering, procurement, and finance professionals to build a comprehensive and defensible cost picture. The process unfolds in a logical sequence, with each step building upon the last to create a granular and robust estimate.

This operational cadence ensures that the final should-cost model is not an academic exercise, but a practical tool grounded in the realities of manufacturing and service delivery. It is a core operational competency for any organization seeking to achieve mastery over its supply chain costs.

The successful execution of this analysis hinges on a rigorous, multi-step methodology. This structured approach ensures that all potential costs are identified, quantified, and validated, leading to a highly credible negotiation baseline. It is a process of systematic investigation, moving from the high-level product specification to the most granular cost elements.

- Define Scope and Deconstruct the Work ▴ The process begins with a thorough deconstruction of the product or service using a Work Breakdown Structure (WBS). For a physical product, this involves creating a detailed Bill of Materials (BOM) from engineering drawings and specifications. For a service, this means defining every discrete activity and deliverable required by the service level agreement.

- Quantify and Price Direct Materials ▴ Each item on the BOM is quantified. Procurement specialists then apply current market pricing to these quantities. This involves gathering quotes from multiple raw material suppliers, consulting commodity market data (e.g. LME for metals, ICIS for chemicals), and factoring in costs for scrap, waste, and yield loss.

- Calculate Direct Labor Input ▴ Industrial engineers or production specialists estimate the labor hours required for each step of the manufacturing or service delivery process. This can be based on time studies, established industry standards, or expert analysis. These hours are then multiplied by blended, fully-burdened labor rates appropriate for the geographic region and skill level required.

- Analyze and Allocate Overhead ▴ This is often the most complex step. Manufacturing overhead (including factory supervision, utilities, and machine maintenance) is calculated and applied using a logical allocation basis, such as direct labor hours or machine hours. A separate calculation is performed for Selling, General, and Administrative (SG&A) overhead, which is then allocated to the product cost.

- Determine a Fair Profit Margin ▴ The analysis concludes by adding a reasonable profit margin. This is not an arbitrary number; it is determined by analyzing the supplier’s industry, the complexity of the product, the level of risk being assumed by the supplier, and prevailing profit norms for similar goods or services.

- Synthesize and Validate the Model ▴ All cost elements are aggregated into the final should-cost model. This model is then subject to a peer review or validation process, where assumptions are challenged and data sources are verified to ensure the final output is robust, defensible, and ready for use in negotiation.

Quantitative Modeling in Practice

The analytical core of the execution phase is the direct comparison of the internal should-cost model against the proposals received from suppliers. This quantitative analysis moves beyond simple price comparison to a structural evaluation of each supplier’s bid. The goal is to pinpoint not just that a supplier’s price is higher, but precisely where and why it is higher.

This diagnostic capability is what transforms the analysis from a simple estimating exercise into a powerful negotiation weapon. The table below presents a hypothetical scenario, comparing the internal should-cost model with proposals from three different suppliers for the same component.

| Cost Element | Internal Should-Cost Model ($) | Supplier A Bid (Implied, $) | Variance A (%) | Supplier B Bid (Implied, $) | Variance B (%) | Supplier C Bid (Implied, $) | Variance C (%) |

|---|---|---|---|---|---|---|---|

| Direct Materials | 9.80 | 11.50 | +17.3% | 10.10 | +3.1% | 9.90 | +1.0% |

| Direct Labor | 12.00 | 12.50 | +4.2% | 14.00 | +16.7% | 12.20 | +1.7% |

| Manufacturing Overhead | 3.70 | 4.50 | +21.6% | 4.00 | +8.1% | 5.00 | +35.1% |

| SG&A Overhead | 3.50 | 3.80 | +8.6% | 3.60 | +2.9% | 4.50 | +28.6% |

| Total Cost | 29.00 | 32.30 | 31.70 | 31.60 | |||

| Profit Margin | 4.35 (15%) | 6.46 (20%) | +48.5% | 4.76 (15%) | +9.4% | 7.90 (25%) | +81.6% |

| Final Price | 33.35 | 38.76 | 36.46 | 39.50 |

This comparative analysis immediately reveals distinct narratives for each supplier. Supplier A appears to have significant issues in their material sourcing or has embedded a large risk premium in their material costs. Supplier B is competitive on materials but shows potential labor inefficiencies or higher wage structures.

Supplier C, while efficient in core production costs, carries a substantially higher overhead and profit expectation. This level of insight allows the negotiation team to tailor its strategy for each supplier, focusing on the specific areas of variance.

Executing a bottom-up analysis provides a granular, data-driven map to navigate the complexities of supplier pricing and uncover hidden value.

Translating Analysis into Negotiation Levers

The final stage of execution is the weaponization of the analysis. The quantitative insights are translated into specific, actionable negotiation levers. These are not blunt demands for a lower price; they are sophisticated, data-informed inquiries and proposals designed to probe specific cost elements and drive toward the should-cost target.

This approach empowers the negotiation team to control the dialogue, frame the discussion around objective facts, and systematically dismantle a supplier’s justifications for an inflated price. The ultimate goal is to align the supplier’s price with the efficient benchmark established by the should-cost model, creating value for the buying organization.

- Material Cost Audits ▴ For a supplier like A, the negotiation can focus on material costs. The team can present its market data and ask the supplier to provide evidence for their higher costs, potentially leading to discussions about joint sourcing, alternative materials, or long-term contracting to secure better pricing.

- Process Efficiency Reviews ▴ With a supplier like B, the conversation can center on labor and process efficiency. The team might propose a collaborative value analysis/value engineering (VAVE) event to identify and remove non-value-added activities from the production process, sharing the resulting savings.

- Overhead and Profit Rationalization ▴ For a supplier like C, the negotiation must address the commercial structure of the deal. The team can challenge the high overhead allocation and excessive profit margin, using industry benchmarks to argue for a more reasonable structure that reflects the actual complexity and risk of the business.

- Unbundling and Re-bundling ▴ The analysis allows the team to “unbundle” costs. For instance, they can ask for the price without logistics included, and then source transportation separately if the supplier’s logistics costs are too high. Conversely, they can propose bundling larger volumes for price concessions based on modeled economies of scale.

References

- Monczka, Robert M. et al. Purchasing and Supply Chain Management. Cengage Learning, 2015.

- Dobler, Donald W. and David N. Burt. Purchasing and Supply Management ▴ Text and Cases. McGraw-Hill, 1996.

- Garrison, Ray H. et al. Managerial Accounting. 16th ed. McGraw-Hill Education, 2018.

- National Contract Management Association. The Contract Management Body of Knowledge (CMBOK). 6th ed. 2019.

- Steele, Paul, and Brian Court. Profitable Purchasing Strategies ▴ A Manager’s Guide for Improving Organizational Competitiveness Through Better Buying. McGraw-Hill, 1996.

- Ashenbaum, Bryan, and William L. Michels. The Procurement and Supply Manager’s Desk Reference. John Wiley & Sons, 2011.

- Council of the Inspectors General on Integrity and Efficiency. “Contract Cost and Price Analysis Guide.” 2011.

- U.S. Government Accountability Office. “GAO Cost Estimating and Assessment Guide ▴ Best Practices for Developing and Managing Capital Program Costs.” GAO-09-3SP, 2009.

Reflection

Calibrating the Organizational Lens

Integrating a bottom-up cost analysis into the procurement function is an exercise in organizational transformation. It requires a commitment to developing a deep, systemic understanding of the markets in which a company operates and the products it buys. The process itself builds institutional muscle, fostering a culture of analytical rigor and data-driven decision-making.

The should-cost model becomes more than a negotiation tool; it evolves into a dynamic lens through which the organization views its supply chain, revealing inefficiencies, illuminating risks, and uncovering opportunities for profound value creation. The ultimate role of this analysis is to provide the clarity needed to exert precise control over the economic architecture of a company’s supply base.

Glossary

Cost Analysis

Profit Margin

Should-Cost Model

Bill of Materials

Variance Analysis

Manufacturing Overhead

Work Breakdown Structure

Direct Materials